- Vous êtes ici :

- Accueil

Étudespratiques

| Secteur : | Construction d’équipements |

| Materiau : | Aciers non alliés à hautement alliés |

| Procédés de soudage : | Soudage TIG |

| Mots-clés : | Phoenix, Taurus, Acier, magschweissen, |

The user-friendly way to process all kinds of material thicknesses

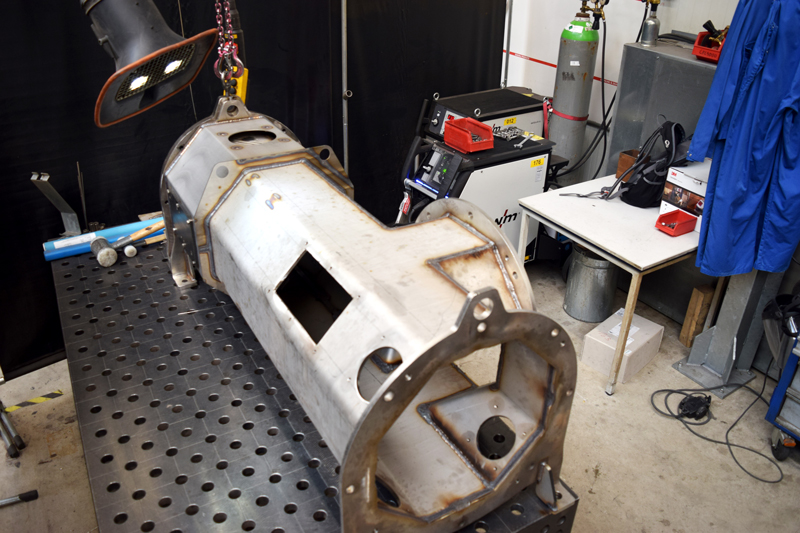

La situation de départ :

With its machines, the Essen-Oldenburg-based company focuses on the waste management, abattoir, fishing and agricultural sectors. Almost all of its products involve welding work on a wide range of materials, including unalloyed and low-alloy construction steels or chrome-nickel steels with various material thicknesses. This diverse spectrum of work is bolstered by Vogelsang’s high degree of vertical integration. With such a wide range of materials and material thicknesses, the company has high demands for ist welding machines.

With its machines, the Essen-Oldenburg-based company focuses on the waste management, abattoir, fishing and agricultural sectors. Almost all of its products involve welding work on a wide range of materials, including unalloyed and low-alloy construction steels or chrome-nickel steels with various material thicknesses. This diverse spectrum of work is bolstered by Vogelsang’s high degree of vertical integration. With such a wide range of materials and material thicknesses, the company has high demands for ist welding machines.

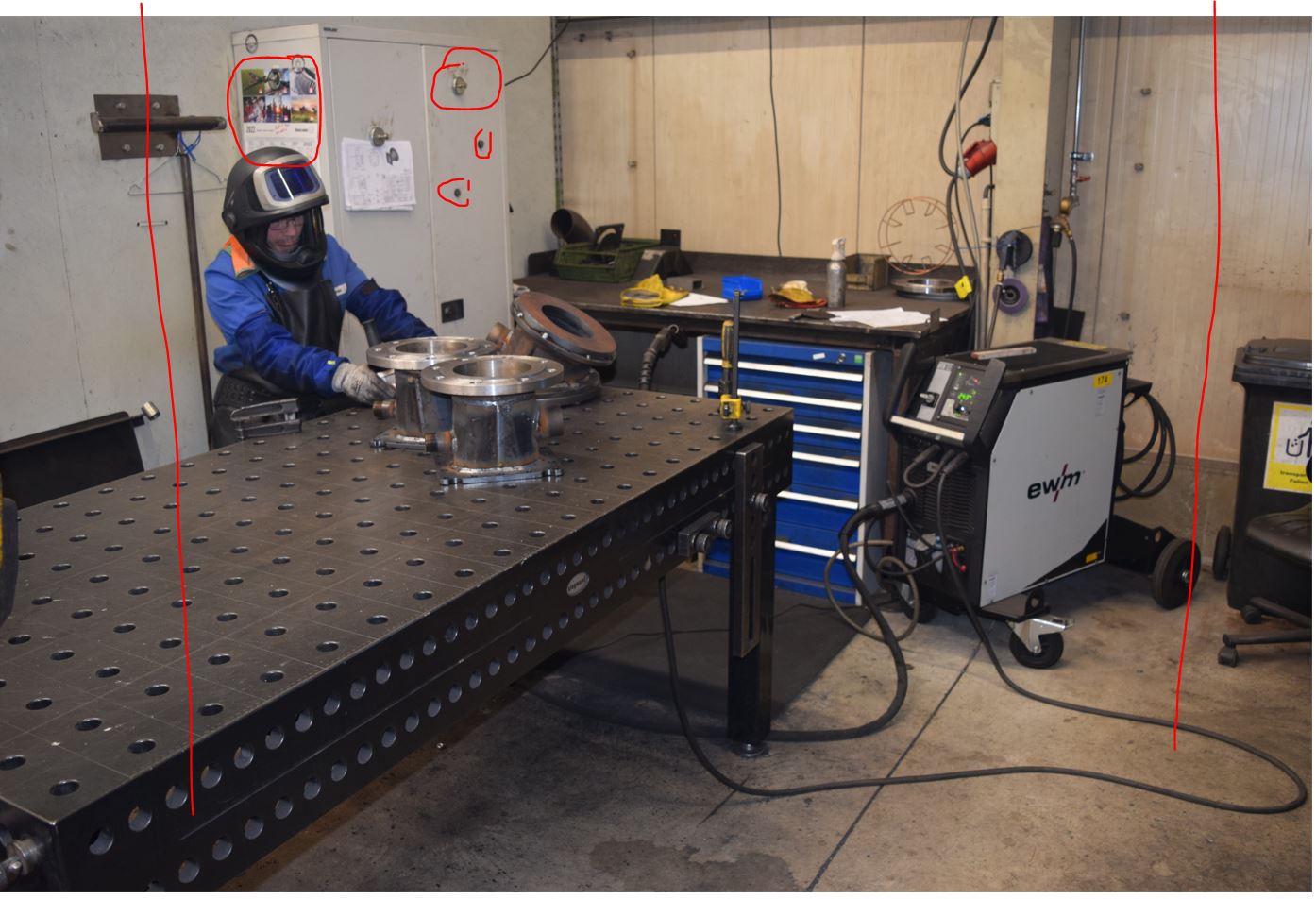

La solution :

In 2021, the company quickly settled on EWM’s new XQ series. Vogelsang was immediately blown away by what was possible with the new power sources, noting in particular how user-friendly the machines were. The saved JOBs for different materials and material thicknesses were a particular highlight for the company, offering potential to significantly simplify work sequences. These allow the welder to load optimised, pre-programmed machine settings for every task.

In 2021, the company quickly settled on EWM’s new XQ series. Vogelsang was immediately blown away by what was possible with the new power sources, noting in particular how user-friendly the machines were. The saved JOBs for different materials and material thicknesses were a particular highlight for the company, offering potential to significantly simplify work sequences. These allow the welder to load optimised, pre-programmed machine settings for every task.

La réussite :

The new XQ machines and their processes allow the company to work with extremely low spatter. They also significantly reduce the amount of post-weld work required. In just a few weeks, the positive effects of the XQ welding machines on energy and material consumption will also be clear to see. The machine users were also impressed: they wanted to replace all welding machines with the MIG/MAG XQ series as soon as the first machines were commissioned.

The new XQ machines and their processes allow the company to work with extremely low spatter. They also significantly reduce the amount of post-weld work required. In just a few weeks, the positive effects of the XQ welding machines on energy and material consumption will also be clear to see. The machine users were also impressed: they wanted to replace all welding machines with the MIG/MAG XQ series as soon as the first machines were commissioned.