- Du er her:

- Hjem

PraxisReport

| Bransje: | Stålkonstruksjon |

| Materiale: | u- til lavlegert stål |

| Sveiseprosesser: | Xnet |

| Nøkkelord: | Xnet, Nettverkskobling, Beregne, Optimere, Sveisestyringsprogramvare, |

Get certifiable quality with EWM

Utgangspunktet:

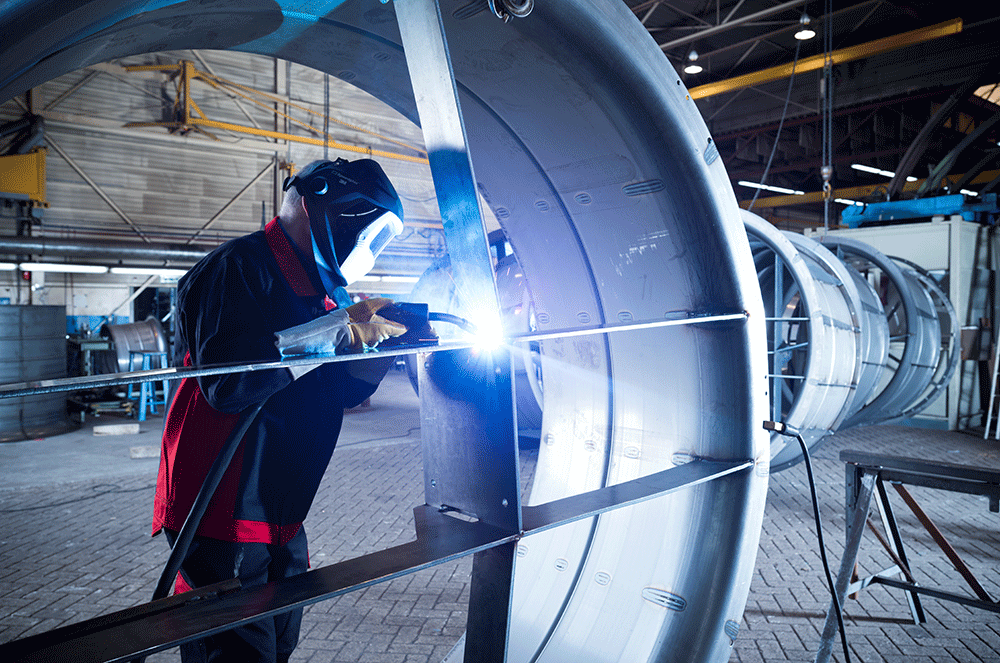

The heat exchangers complete with steel constructions manufactured by Geha are used worldwide, even under very climatically challenging conditions. Geha already had EWM welding machines with the oldest one dating back to 2002. The aim was to network all the machines and continuously record all the welding parameters to be able to reliably prove the weld seam quality at any time. According to Franc van Wilgen, Managing Director of Geha B.V., continuous welding data recording is becoming more and more important. Quality can really only be proven through continuously recorded data. These requirements now apply for compliance with DIN EN 1090.

The heat exchangers complete with steel constructions manufactured by Geha are used worldwide, even under very climatically challenging conditions. Geha already had EWM welding machines with the oldest one dating back to 2002. The aim was to network all the machines and continuously record all the welding parameters to be able to reliably prove the weld seam quality at any time. According to Franc van Wilgen, Managing Director of Geha B.V., continuous welding data recording is becoming more and more important. Quality can really only be proven through continuously recorded data. These requirements now apply for compliance with DIN EN 1090.

Løsningen:

After pre-installation of LAN cables – there is too much steel in Geha’s production to establish a WiFi connection as steel disrupts radio communications necessary for a WiFi network – all five welding machines were integrated into the network within one day. Since then, Geha has used ewm Xnet to log all the data for the five welding machines completely automatically online. This allows the data to be analysed and evaluated by welding coordination personnel, both in real-time and also at a later point. Data are recorded offline on external construction sites and stored temporarily on a storage medium. The data are then transferred to the server.

After pre-installation of LAN cables – there is too much steel in Geha’s production to establish a WiFi connection as steel disrupts radio communications necessary for a WiFi network – all five welding machines were integrated into the network within one day. Since then, Geha has used ewm Xnet to log all the data for the five welding machines completely automatically online. This allows the data to be analysed and evaluated by welding coordination personnel, both in real-time and also at a later point. Data are recorded offline on external construction sites and stored temporarily on a storage medium. The data are then transferred to the server.

Resultatet:

ewm Xnet guarantees welding quality, makes it possible to prove quality and helps the welder to work proactively. The welding data allow welders to determine the optimum time to change wear parts so as to leave them on for as long as possible. This has two advantages in terms of savings: It means that working, functional parts are not exchanged, thus postponing downtimes as much as possible and increasing welding productivity. Using ewm Xnet means that Geha can always be sure that they have manufactured their products to the required quality – and can prove it.

ewm Xnet guarantees welding quality, makes it possible to prove quality and helps the welder to work proactively. The welding data allow welders to determine the optimum time to change wear parts so as to leave them on for as long as possible. This has two advantages in terms of savings: It means that working, functional parts are not exchanged, thus postponing downtimes as much as possible and increasing welding productivity. Using ewm Xnet means that Geha can always be sure that they have manufactured their products to the required quality – and can prove it.