- 我在这里:

- 首页

CustomerStory

| Industry: | Pipe construction |

| Material: | Steel |

| Welding processes: | Degauss |

| Keywords: | Degauss 600, Entmagnetisieren, Activegauss, Degaussing, Pipeline, E-Hand-Schweißen, Magnetismus, |

Degaussing of pipelines

The challenge:

The Stuttgart-based company, terranets bw GmbH, connects Baden-Württemberg and the surrounding countries to European energy infrastructure. The gas transport lines and systems are controlled and monitored using a high-quality fibreglass network to ensure an efficient, round-the-clock supply. As high-pressure gas lines must comply with the strictest safety standards, terranets bw GmbH, as the operating company, regularly inspects pipe wall thicknesses using so-called “pigs”. However, this inspection system can be problematic as it magnetises the pipelines. If repairs are needed, this magnetisation causes arc deflection during welding, resulting in trapped pores in the weld and a lack of fusion.

The Stuttgart-based company, terranets bw GmbH, connects Baden-Württemberg and the surrounding countries to European energy infrastructure. The gas transport lines and systems are controlled and monitored using a high-quality fibreglass network to ensure an efficient, round-the-clock supply. As high-pressure gas lines must comply with the strictest safety standards, terranets bw GmbH, as the operating company, regularly inspects pipe wall thicknesses using so-called “pigs”. However, this inspection system can be problematic as it magnetises the pipelines. If repairs are needed, this magnetisation causes arc deflection during welding, resulting in trapped pores in the weld and a lack of fusion.

The solution:

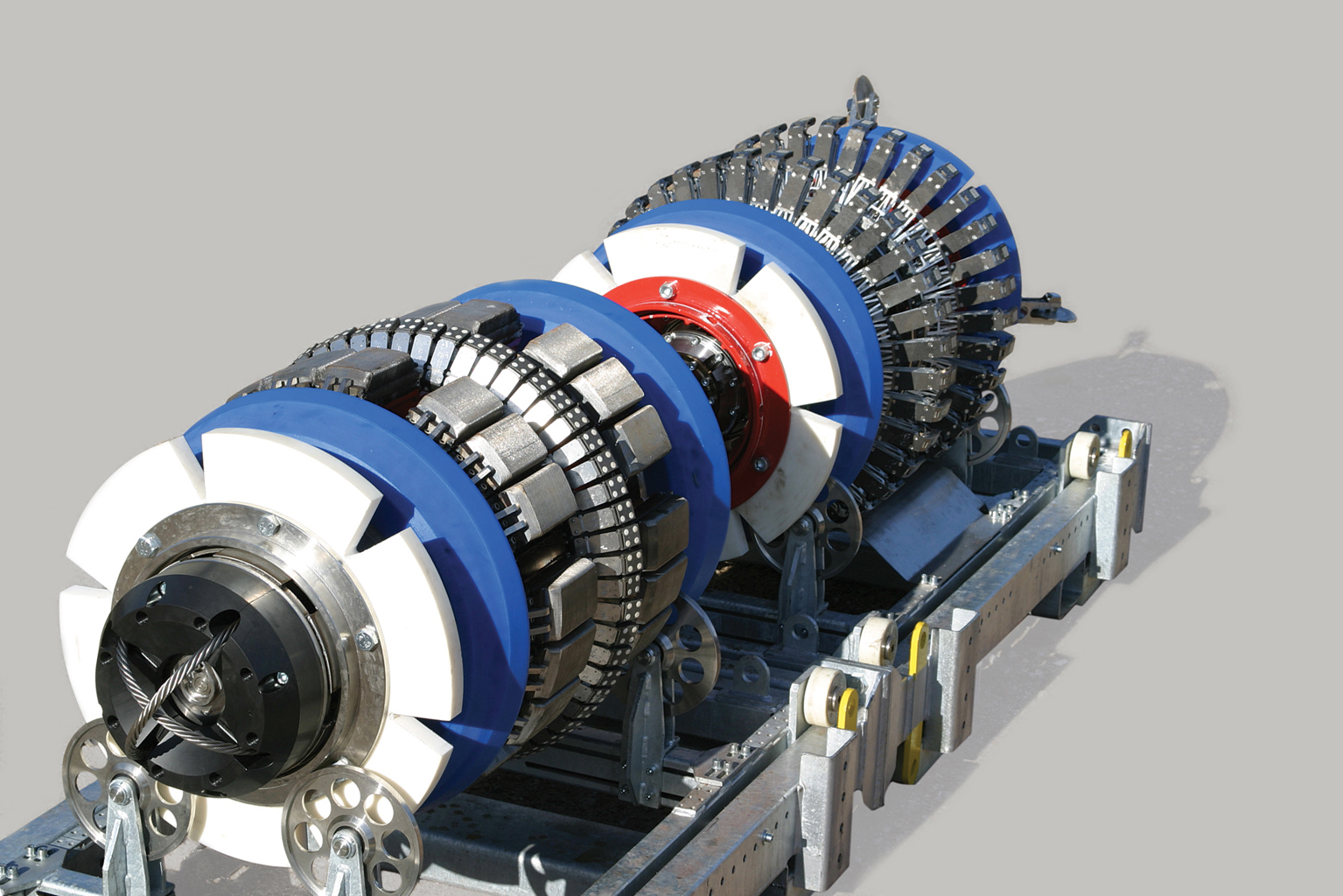

To solve this problem, EWM AG developed the Degauss 600 degaussing machine. The handy, compact machine is both user-friendly and suitable for use on the construction site. To degauss the pipe, a power cable is coiled around it as tightly as possible. A current flow through the cable then creates an opposing magnetic field of equal strength to eliminate the residual magnetism. The more coils are wrapped around the pipe, the greater the maximum field strength that can be generated with a constant current. The Degauss 600 is able to degauss in two ways: Using the degauss function, the current flow starts off high and is subsequently reduced in steps and alternating polarity. This has the effect of degaussing the component. This method is great for short components. In contrast, the activgauss method is suitable for long components such as pipelines. Using the activgauss method, the current flows continuously through the coils to create a permanent magnetic field.

To solve this problem, EWM AG developed the Degauss 600 degaussing machine. The handy, compact machine is both user-friendly and suitable for use on the construction site. To degauss the pipe, a power cable is coiled around it as tightly as possible. A current flow through the cable then creates an opposing magnetic field of equal strength to eliminate the residual magnetism. The more coils are wrapped around the pipe, the greater the maximum field strength that can be generated with a constant current. The Degauss 600 is able to degauss in two ways: Using the degauss function, the current flow starts off high and is subsequently reduced in steps and alternating polarity. This has the effect of degaussing the component. This method is great for short components. In contrast, the activgauss method is suitable for long components such as pipelines. Using the activgauss method, the current flows continuously through the coils to create a permanent magnetic field.

The success:

The Degauss 600 is easy to operate thanks to its light weight and compact size, perfect for use on the construction site. As it comes with a remote control, the power source can even be placed outside the excavation. The problem of magnetism when repair welding in pipe construction is not a problem anymore with the Degauss 600, even when there are strong magnetic fields. Seeing the degaussing machine in action on terranets bw GmbH’s construction sites didn’t only convince the operating company itself of how great this machine is, but construction contractors Leonhard & Weiss GmbH and the responsible, independent inspecting engineer from TÜV Süd were also blown away by it.

The Degauss 600 is easy to operate thanks to its light weight and compact size, perfect for use on the construction site. As it comes with a remote control, the power source can even be placed outside the excavation. The problem of magnetism when repair welding in pipe construction is not a problem anymore with the Degauss 600, even when there are strong magnetic fields. Seeing the degaussing machine in action on terranets bw GmbH’s construction sites didn’t only convince the operating company itself of how great this machine is, but construction contractors Leonhard & Weiss GmbH and the responsible, independent inspecting engineer from TÜV Süd were also blown away by it.