It’s beginning

Your all-new welding experience.

Digital, universal, personal – reimagined without compromise, the new era of welding starts now with the TETRIX XQ. Smart networking. Robust operation. Sophisticated casing. Revolutionary control. The innovative XQ technology with Power Factor Correction (PFC) enables high-performance welding technology with a current of up to 230 A directly from a single-phase 230-V power socket. For the best welding results you’ve ever achieved.

-

-

Technical data Tetrix XQ 350 puls DC 5P

Version Tetrix XQ 350 puls DC W Comfort 3.0 5P R1 5m Setting range for welding current 3 A - 350 A Duty cycle 40 °C 350 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains voltage (possible) 3 x 440 V - 460 V Mains voltage (possible) 3 x 480 V - 500 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 14.3 kVA Efficiency 90 % Power consumption Pi 25 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 126.5 kg / 278.9 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 400 puls DC 5P

Version Tetrix XQ 400 puls DC W Comfort 3.0 5P R1 5m Setting range for welding current 3 A - 400 A Duty cycle 40 °C 400 A / 80 % 370 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains voltage (possible) 3 x 440 V - 460 V Mains voltage (possible) 3 x 480 V - 500 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 17.8 kVA Efficiency 90 % Power consumption Pi 25 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 126.5 kg / 278.9 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 500 puls DC 5P

Version Tetrix XQ 500 puls DC W Comfort 3.0 5P R1 5m Setting range for welding current 3 A - 500 A Duty cycle 40 °C 500 A / 80 % 470 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains voltage (possible) 3 x 440 V - 460 V Mains voltage (possible) 3 x 480 V - 500 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 25.5 kVA Efficiency 90 % Power consumption Pi 27 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 128.5 kg / 283.3 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 600 puls DC 5P

Version Tetrix XQ 600 puls DC W Comfort 3.0 5P R1 5m Setting range for welding current 3 A - 600 A Duty cycle 40 °C 600 A / 40 % 550 A / 60 % 470 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains voltage (possible) 3 x 440 V - 460 V Mains voltage (possible) 3 x 480 V - 500 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 34.8 kVA Efficiency 90 % Power consumption Pi 27 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 128.5 kg / 283.3 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 350 puls DC 8P

Version Tetrix XQ 350 puls DC W Comfort 3.0 8P R1 5m Setting range for welding current 3 A - 350 A Duty cycle 40 °C 350 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains voltage (possible) 3 x 440 V - 460 V Mains voltage (possible) 3 x 480 V - 500 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 14.3 kVA Efficiency 90 % Power consumption Pi 25 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 126.5 kg / 278.9 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Daten Tetrix XQ 400 puls DC 8P

Version Tetrix XQ 400 puls DC W Comfort 3.0 8P R1 5m Setting range for welding current 3 A - 400 A Duty cycle 40 °C 400 A / 80 % 370 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains voltage (possible) 3 x 440 V - 460 V Mains voltage (possible) 3 x 480 V - 500 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 17.8 kVA Efficiency 90 % Power consumption Pi 25 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 126.5 kg / 278.9 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 500 puls DC 8P

Version Tetrix XQ 500 puls DC W Comfort 3.0 8P R1 5m Setting range for welding current 3 A - 500 A Duty cycle 40 °C 500 A / 80 % 470 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains voltage (possible) 3 x 440 V - 460 V Mains voltage (possible) 3 x 480 V - 500 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 25.5 kVA Efficiency 90 % Power consumption Pi 27 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 128.5 kg / 283.3 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 600 puls DC 8P

Version Tetrix XQ 600 puls DC W Comfort 3.0 8P R1 5m Setting range for welding current 3 A - 600 A Duty cycle 40 °C 600 A / 40 % 550 A / 60 % 470 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains voltage (possible) 3 x 440 V - 460 V Mains voltage (possible) 3 x 480 V - 500 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 34.8 kVA Efficiency 90 % Power consumption Pi 27 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 128.5 kg / 283.3 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A

-

TIG DC Functions

Standard DC

Perfect TIG welding with ignition parameters adapted depending on power output.

Pulsed TIG DC welding

Decreases the heat input which reduces distortion and discolouration.

spotmatic

Triggers constant tack points only upon contact with the torch tip.

spotArc

Minimised time required for tacking and spot welding due to individual triggering of the tack points with the torch trigger.

activArc

Dynamic TIG arc with automatic arc stabilisation. The high arc force ensures a secure sidewall fusion and a targeted and uniform heat input. Particularly beneficial when welding fillet welds and root passes.

HF start

Prevents tungsten inclusions through non-contact arc ignition.

liftArc

Simple ignition of the arc without HF by pulling up the welding torch electrode after touching the workpiece.

TIG Antistick

Prevents damage to tungsten electrode in case of inadvertent contact with the workpiece.

TIG AC functions

Standard AC

Aluminium welding in just one click thanks to perfect presets. Easy adjustment of AC parameters for special applications.

Pulsed TIG DC welding

Reduced distortion and discolouration through energy per unit length and heat input.

AC balling

Ensures optimum tungsten balling and therefore a stable, easy-to-handle arc.

AC frequency

Adjustment of the arc force – ideal for thin metal sheets and fillet welds.

AC balance

Vary between more positive and more negative current proportion.

AC amplituden balance

Enables adjustment of negative and positive welding current.

AC waveforms

Optimum stability and reduced noise level thanks to adjustable AC waveforms (sine, trapezoidal, square and customised).

MMA functions

Standard MMA

Unlimited potential applications for electrode welding.

Hotstart

Prevents a lack of fusion at the start of the weld seam by briefly increasing the current when welding begins.

Arcforce

Adjustable arc dynamics from soft to hard.

Antistick

Prevents the electrode from annealing by briefly switching off the welding current.

Cel

100% reliable vertical-down welding with all cellulose electrodes.

MMA pulse welding

Vertical-up welding without using the “Christmas tree” technique, but still with reliable root fusion..

-

-

-

Technical data Tetrix XQ 350 puls AC/DC 5P

Version Tetrix XQ 350 puls AC/DC W Comfort 3.0 5P R1 5m Setting range for welding current 3 A - 350 A Duty cycle 40 °C 350 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 14.7 kVA Efficiency 88 % Power consumption Pi 28 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 128.5 kg / 283.3 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 400 puls AC/DC 5P

Version Tetrix XQ 400 puls AC/DC W Comfort 3.0 5P R1 5m Setting range for welding current 3 A - 400 A Duty cycle 40 °C 400 A / 80 % 370 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 18.1 kVA Efficiency 88 % Power consumption Pi 28 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 129.5 kg / 285.5 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 500 puls AC/DC 5P

Version Tetrix XQ 500 puls AC/DC W Comfort 3.0 5P R1 5m Setting range for welding current 3 A - 500 A Duty cycle 40 °C 500 A / 40 % 400 A / 80 % 370 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 26.2 kVA Efficiency 88 % Power consumption Pi 30 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 129.5 kg / 285.5 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 350 puls AC/DC 8P

Version Tetrix XQ 350 puls AC/DC W Comfort 3.0 8P R1 5m Setting range for welding current 3 A - 350 A Duty cycle 40 °C 350 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 14.7 kVA Efficiency 88 % Power consumption Pi 28 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 128.5 kg / 283.3 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 400 puls AC/DC 8P

Version Tetrix XQ 400 puls AC/DC W Comfort 3.0 8P R1 5m Setting range for welding current 3 A - 400 A Duty cycle 40 °C 400 A / 80 % 370 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 18.1 kVA Efficiency 88 % Power consumption Pi 28 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 129.5 kg / 285.5 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A Technical data Tetrix XQ 500 puls AC/DC 8P

Version Tetrix XQ 500 puls AC/DC W Comfort 3.0 8P R1 5m Setting range for welding current 3 A - 500 A Duty cycle 40 °C 500 A / 40 % 400 A / 80 % 370 A / 100 % Open circuit voltage 82 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 26.2 kVA Efficiency 88 % Power consumption Pi 30 W Cooling capacity at 1 l/min. 1500 W Pump pressure 3.5 bar Tank capacity 8 l Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch Weight 129.5 kg / 285.5 lbs Standards IEC 60974-1, -2, -3 and -10 CL.A

-

TIG DC Functions

Standard DC

Perfect TIG welding with ignition parameters adapted depending on power output.

Pulsed TIG DC welding

Decreases the heat input which reduces distortion and discolouration.

spotmatic

Triggers constant tack points only upon contact with the torch tip.

spotArc

Minimised time required for tacking and spot welding due to individual triggering of the tack points with the torch trigger.

activArc

Dynamic TIG arc with automatic arc stabilisation. The high arc force ensures a secure sidewall fusion and a targeted and uniform heat input. Particularly beneficial when welding fillet welds and root passes.

HF start

Prevents tungsten inclusions through non-contact arc ignition.

liftArc

Simple ignition of the arc without HF by pulling up the welding torch electrode after touching the workpiece.

TIG Antistick

Prevents damage to tungsten electrode in case of inadvertent contact with the workpiece.

TIG AC functions

Standard AC

Aluminium welding in just one click thanks to perfect presets. Easy adjustment of AC parameters for special applications.

Pulsed TIG DC welding

Reduced distortion and discolouration through energy per unit length and heat input.

AC balling

Ensures optimum tungsten balling and therefore a stable, easy-to-handle arc.

AC frequency

Adjustment of the arc force – ideal for thin metal sheets and fillet welds.

AC balance

Vary between more positive and more negative current proportion.

AC amplituden balance

Enables adjustment of negative and positive welding current.

AC waveforms

Optimum stability and reduced noise level thanks to adjustable AC waveforms (sine, trapezoidal, square and customised).

MMA functions

Standard MMA

Unlimited potential applications for electrode welding.

Hotstart

Prevents a lack of fusion at the start of the weld seam by briefly increasing the current when welding begins.

Arcforce

Adjustable arc dynamics from soft to hard.

Antistick

Prevents the electrode from annealing by briefly switching off the welding current.

Cel

100% reliable vertical-down welding with all cellulose electrodes.

MMA pulse welding

Vertical-up welding without using the “Christmas tree” technique, but still with reliable root fusion..

-

-

An overview of the Tetrix XQ series

TETRIX XQ puls DC

- / TIG

- / MMA

- / Standard DC

- / Pulsed TIG DC welding

- / spotmatic

- / spotArc

- / activArc

- / HF start

- / liftArc

- / TIG Antistick

TIG functions

- / Standard MMA

- / Hotstart

- / Arcforce

- / Antistick

- / Cel

- / MMA pulse welding

MMA functions

TETRIX XQ puls AC/DC

- / TIG

- / MMA

- / Standard DC

- / Pulsed TIG DC welding

- / spotmatic

- / spotArc

- / activArc

- / HF start

- / liftArc

- / TIG Antistick

- / Standard AC

- / Pulsed TIG welding

TIG functions

- / AC balling

- / AC frequency

- / AC balance

- / AC amplitude balance

- / AC waveforms

- / Standard MMA

- / Hotstart

- / Arcforce

- / Antistick

- / Cel

- / MMA pulse welding

MMA functions

IT MAKES YOU EVEN BETTER – the new TETRIX XQ demodular

TETRIX XQ HAS ALL YOU NEED TO MAKE YOUR WELDING PERFECT.

WHATEVER YOU’RE PLANNING. Making every welding task fun.

Whether DC or AC/DC, gas or water-cooled – the Tetrix XQ series has an individual solution for every need. The machines boast an above-average duty cycle to make your work more eff ective and, thanks to the wide range of accessories, there’s always a machine to meet any special, unusual requirements.

ALWAYS AT HAND.

The ergonomic handles allow you to move your machine safely and effortlessly. The workpiece lead or torch hose package can be properly fixed to the handles. There welding torch.

FULLY CONNECTABLE.

Your Tetrix XQ is outfitted with an interface for remote controls as standard. There’s also a 7-pole digital interface for your ewm Xnet welding management software.

ALWAYS IN SIGHT.

The large LED infobar with four unambiguous signal colours always shows you the current operating status of your TETRIX XQ.

INTELLIGENT CONNECTIONS.

Connections tilted slightly downwards on the front and back reduce the risk of connected cables kinking. You can easily connect all cable connections without tools.

Protected control.

The protective cap protects against water, dirt and impact.

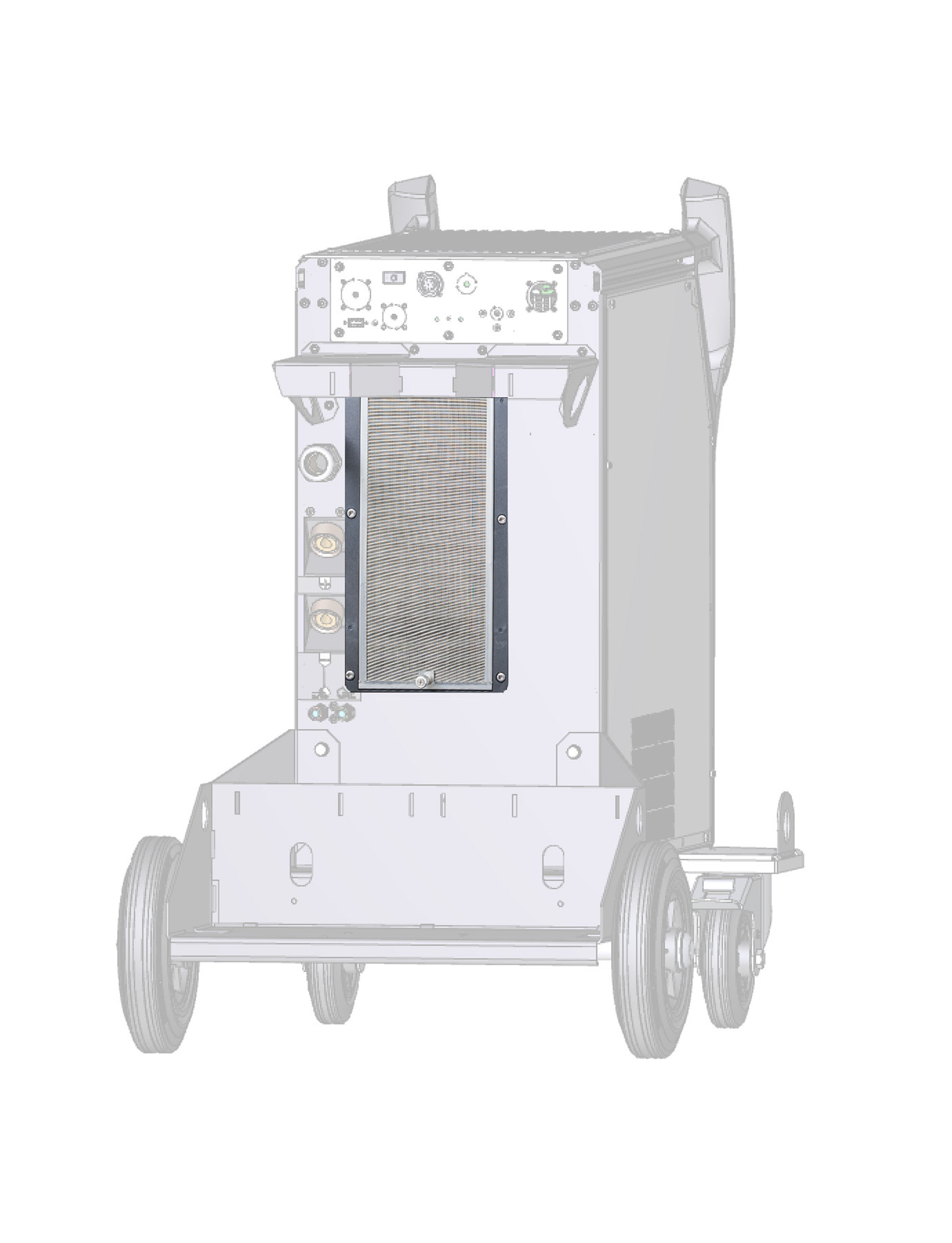

NO DISRUPTIVE AIR.

The new grille ensures that the airflow is diverted downwards so that it doesn’t disrupt you or the welding process.

LARGE WHEELS FOR ANY PURPOSE.

Wheels with a generous 250 mm diameter allow the welding machine to be easily moved and effortlessly overcome obstacles such as cables or thresholds. The large track widths ensure stability, even on inclinations of up to 15°.

Now it’s getting personal. The best controls for your best welding.

-

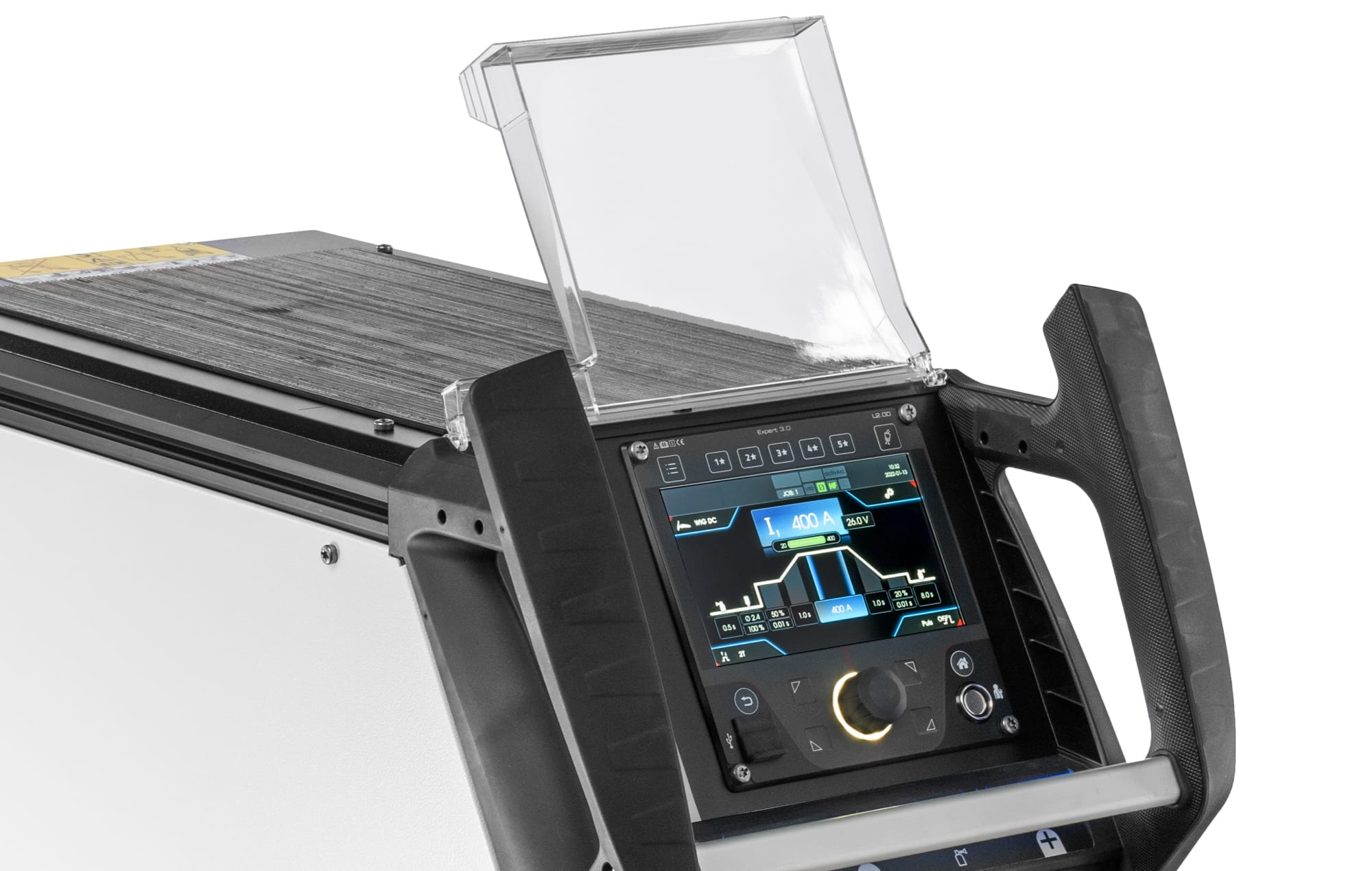

Expert 3.0You want perfect welding results, and that's exactly what you get. The Expert 3.0 control provides you with the ideal basis for this. It is available for all MIG/MAG-XQ welding machines and offers you an unrivalled level of intuitive operability. The possibilities for customising your welding experience are (almost) limitless. Experience welding at the highest level.

-

Comfort 3.0 DCThe Comfort 3.0 control unit impresses with its user-friendly and practice-oriented features. Two large, easy-to-read 7-segment displays ensure a clear presentation of all essential information. Five favorite buttons allow quick access to frequently used settings. Thanks to the ergonomic click-wheel, comfortable operation is guaranteed even when wearing welding gloves. In addition, the robust push-buttons provide reliable and precise control. All relevant functions are directly accessible. With Comfort 3.0, you always have all parameters in view – for efficient work and maximum control during welding.

-

Comfort 3.0 AC/DCThe Comfort 3.0 control unit impresses with its user-friendly and practice-oriented features. Two large, easy-to-read 7-segment displays ensure a clear presentation of all essential information. Five favorite buttons allow quick access to frequently used settings. Thanks to the ergonomic click-wheel, comfortable operation is guaranteed even when wearing welding gloves. In addition, the robust push-buttons provide reliable and precise control. All relevant functions are directly accessible. With Comfort 3.0, you always have all parameters in view – for efficient work and maximum control during welding.

STAY COOL AND CLEAN, ALL THE TIME.

THE NEW COOLING SYSTEM AND AIR ROUTING OF THE TETRIX XQ ENSURE TOP PERFORMANCE.

We have developed a new cooling system to keep your welding torch well cooled, even under the heaviest loads. With excellent cooling capacity and integrated flow and temperature monitoring, it’s the perfect addition to your new TETRIX XQ, even at high currents and over long durations. Air routing of the TETRIX XQ operates in a targeted way, so only those parts which really need to be cooled are cooled. The sophisticated design minimises contamination, even in rough environments.

Inside values.

- Need-based fan control

- Flow monitoring as standard

- Temperature monitoring as standard

- Powerful pump

Air escape on the side.

The air escape is located on the side of the welding machine to prevent contamination from the workplace entering the machine – no interruptions for you or the welding process.

SECURE WATER CONNECTION

The water connections are recessed and optimally protected against damage.

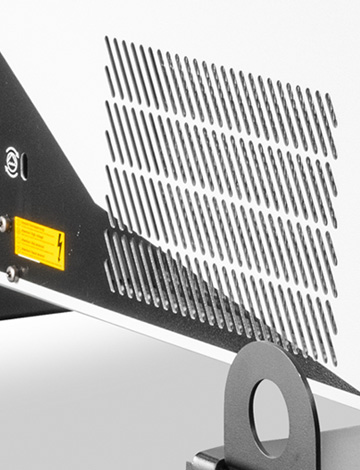

NO DISTURBING AIR.

The new gill field ensures that the airflow is directed downward and does not disturb you or the welding process.

FILLING LEVEL INDICATOR AND INSTRUCTIONS IN PLAIN SIGHT.

You can easily check the filling level of the coolant from the indicator on the front, right next to the operating information.

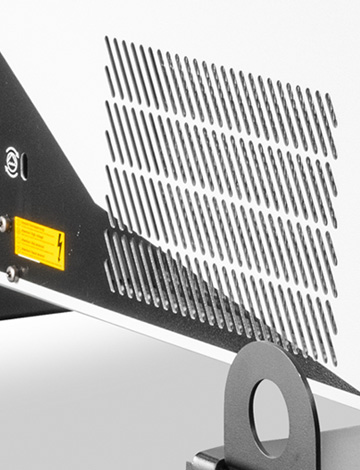

DUST FILTER. NOTHING GETS THROUGH.

The reusable stainless-steel dust filter for the welding machine and cooling system can be mounted without tools.

ewm Xnet

DIGITISE ANY WELDING OPERATION.

THE EWM XNET WELDING MANAGEMENT SYSTEM AND XBUTTON.

Better output for less money? Impossible? Or not!

Xnet digitises your welding operations, making it the perfect addition to your new TETRIX XQ. This future-oriented welding management system organises production, planning, quality management, welding coordination personnel and administration. In this way, it decisively helps you improve efficiency, quality and documentation. This is Welding 4.0 – and our answer to Industry 4.0.

XBUTTON – SMALL BUTTON. BIG EFFECT.

The Xbutton makes your TETRIX XQ even more reliable and a bit more “you”. You can easily transfer all the parameters from your personal welding plan and your specific menu settings to the machine.

Simply be more productive.

With ewm Xnet, you get more done in the same amount of time. Paperless transfer of all relevant data directly to the workplace, fewer error corrections thanks to specified welding parameters and less unnecessary downtime thanks to timely maintenance notices simply allow you to work more efficiently.

XQ series accessories demodular

XQ Series

As is typical for EWM, the system is well thought out and every component has been tested in tough everyday working conditions. Thanks to the wide range of user-oriented accessories, the XQ series can be flexibly adapted to all challenges and applications.

XQ Device Documents

Here you will find documents for the Tetrix XQ series. For more documents and additional operating instructions, please refer to our

Online Shop

Brochures

Operating instructions

Contact

-

-

Technical data Tetrix XQ 230 puls DC 5P

Version Tetrix XQ 230 puls DC Comfort 3.0 5POL 5P Setting range for welding current 3 A - 230 A Duty cycle 40 °C 230 A / 45 % 205 A / 60 % 170 A / 100 % Duty cycle @ 110 V - 120 V 170 A / 40 % 150 A / 60 % 120 A / 100 % Open circuit voltage 96 V Mains voltage (ex works) 1 x 230 V Mains voltage (possible) 1 x 110 V - 120 V Mains tolerances (ex works) -40 % up to +15 % Mains tolerances (ex works) @ 110 V - 120 V -15 % up to +15 % Mains frequency 50 Hz / 60 Hz Recommended generator power 6.9 kVA Recommended generator power @ 110 V - 120 V 4.5 kVA Efficiency 87 % Power consumption Pi 28 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 17.5 kg / 38.6 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data Tetrix XQ 300 puls DC 5P

Version Tetrix XQ 300 puls DC Comfort 3.0 5POL Setting range for welding current 3 A - 300 A Duty cycle 40 °C 300 A / 40 % 270 A / 60 % 220 A / 100 % Open circuit voltage 87 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 15.3 kVA Efficiency 87 % Power consumption Pi 21 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 20.5 kg / 45.2 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data TETRIX XQ 300 SiC puls DC 5P

Version Tetrix XQ 300 SiC puls DC Comfort 3.0 5POL Setting range for welding current 3 A - 300 A Duty cycle 40 °C 300 A / 40 % 270 A / 60 % 220 A / 100 % Open circuit voltage 87 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 14.7 kVA Efficiency 90 % Power consumption Pi 35 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 20.5 kg / 45.2 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data Tetrix XQ 230 puls DC 8P

Version Tetrix XQ 230 puls DC Comfort 3.0 8POL 8P Setting range for welding current 3 A - 230 A Duty cycle 40 °C 230 A / 45 % 205 A / 60 % 170 A / 100 % Duty cycle @ 110 V - 120 V 170 A / 40 % 150 A / 60 % 120 A / 100 % Open circuit voltage 96 V Mains voltage (ex works) 1 x 230 V Mains voltage (possible) 1 x 110 V - 120 V Mains tolerances (ex works) -40 % up to +15 % Mains tolerances (ex works) @ 110 V - 120 V -15 % up to +15 % Mains frequency 50 Hz / 60 Hz Recommended generator power 6.9 kVA Recommended generator power @ 110 V - 120 V 4.5 kVA Efficiency 87 % Power consumption Pi 28 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 17.5 kg / 38.6 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data Tetrix XQ 300 puls DC 8P

Version Tetrix XQ 300 puls DC Comfort 3.0 8POL Setting range for welding current 3 A - 300 A Duty cycle 40 °C 300 A / 40 % 270 A / 60 % 220 A / 100 % Open circuit voltage 87 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 15.3 kVA Efficiency 87 % Power consumption Pi 21 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 20.5 kg / 45.2 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data Tetrix XQ 300 SiC puls DC 8P

Version Tetrix XQ 300 SiC puls DC Comfort 3.0 8POL Setting range for welding current 3 A - 300 A Duty cycle 40 °C 300 A / 40 % 270 A / 60 % 220 A / 100 % Open circuit voltage 87 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 14.7 kVA Efficiency 90 % Power consumption Pi 35 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 20.5 kg / 45.2 lbs Standards IEC 60974-1, -3 and -10 CL.A

-

TIG DC Functions

Standard DC

Perfect TIG welding with ignition parameters adapted depending on power output.

Pulsed TIG DC welding

Decreases the heat input which reduces distortion and discolouration.

spotmatic

Triggers constant tack points only upon contact with the torch tip.

spotArc

Minimised time required for tacking and spot welding due to individual triggering of the tack points with the torch trigger.

activArc

Dynamic TIG arc with automatic arc stabilisation. The high arc force ensures a secure sidewall fusion and a targeted and uniform heat input. Particularly beneficial when welding fillet welds and root passes.

HF start

Prevents tungsten inclusions through non-contact arc ignition.

liftArc

Simple ignition of the arc without HF by pulling up the welding torch electrode after touching the workpiece.

TIG Antistick

Prevents damage to tungsten electrode in case of inadvertent contact with the workpiece.

TIG AC functions

Standard AC

Aluminium welding in just one click thanks to perfect presets. Easy adjustment of AC parameters for special applications.

Pulsed TIG DC welding

Reduced distortion and discolouration through energy per unit length and heat input.

AC balling

Ensures optimum tungsten balling and therefore a stable, easy-to-handle arc.

AC frequency

Adjustment of the arc force – ideal for thin metal sheets and fillet welds.

AC balance

Vary between more positive and more negative current proportion.

AC amplituden balance

Enables adjustment of negative and positive welding current.

AC waveforms

Optimum stability and reduced noise level thanks to adjustable AC waveforms (sine, trapezoidal, square and customised).

MMA functions

Standard MMA

Unlimited potential applications for electrode welding.

Hotstart

Prevents a lack of fusion at the start of the weld seam by briefly increasing the current when welding begins.

Arcforce

Adjustable arc dynamics from soft to hard.

Antistick

Prevents the electrode from annealing by briefly switching off the welding current.

Cel

100% reliable vertical-down welding with all cellulose electrodes.

MMA pulse welding

Vertical-up welding without using the “Christmas tree” technique, but still with reliable root fusion..

-

-

-

Technical data Tetrix XQ 230 puls AC/DC 5P

Version Tetrix XQ 230 puls AC/DC Comfort 3.0 5POL 5P Setting range for welding current 3 A - 230 A Duty cycle 40 °C 230 A / 40 % 200 A / 60 % 170 A / 100 % Duty cycle @ 110 V - 120 V 170 A / 40 % 150 A / 60 % 120 A / 100 % Open circuit voltage 96 V Mains voltage (ex works) 1 x 230 V Mains voltage (possible) 1 x 110 V - 120 V Mains tolerances (ex works) -40 % up to +15 % Mains tolerances (ex works) @ 110 V - 120 V -15 % up to +15 % Mains frequency 50 Hz / 60 Hz Recommended generator power 7.4 kVA Recommended generator power @ 110 V - 120 V 4.7 kVA Efficiency 83 % Power consumption Pi 31 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 19.2 kg / 42.3 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data Tetrix XQ 300 puls AC/DC 5P

Version Tetrix XQ 300 puls AC/DC Comfort 3.0 5POL Setting range for welding current 3 A - 300 A Duty cycle 40 °C 300 A / 40 % 270 A / 60 % 220 A / 100 % Open circuit voltage 87 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 15.9 kVA Efficiency 83 % Power consumption Pi 24 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 22 kg / 48.5 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data Tetrix XQ 300 SiC puls AC/DC 5P

Version Tetrix XQ 300 SiC puls AC/DC Comfort 3.0 5POL Setting range for welding current 3 A - 300 A Duty cycle 40 °C 300 A / 40 % 270 A / 60 % 220 A / 100 % Open circuit voltage 87 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 15.3 kVA Efficiency 87 % Power consumption Pi 37 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 22 kg / 48.5 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data Tetrix XQ 230 puls AC/DC 8P

Version Tetrix XQ 230 puls AC/DC Comfort 3.0 8POL 8P Setting range for welding current 3 A - 230 A Duty cycle 40 °C 230 A / 40 % 200 A / 60 % 170 A / 100 % Duty cycle @ 110 V - 120 V 170 A / 40 % 150 A / 60 % 120 A / 100 % Open circuit voltage 96 V Mains voltage (ex works) 1 x 230 V Mains voltage (possible) 1 x 110 V - 120 V Mains tolerances (ex works) -40 % up to +15 % Mains tolerances (ex works) @ 110 V - 120 V -15 % up to +15 % Mains frequency 50 Hz / 60 Hz Recommended generator power 7.4 kVA Recommended generator power @ 110 V - 120 V 4.7 kVA Efficiency 83 % Power consumption Pi 31 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 19.2 kg / 42.3 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data Tetrix XQ 300 puls AC/DC 8P

Version Tetrix XQ 300 puls AC/DC Comfort 3.0 8POL Setting range for welding current 3 A - 300 A Duty cycle 40 °C 300 A / 40 % 270 A / 60 % 220 A / 100 % Open circuit voltage 87 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 15.9 kVA Efficiency 83 % Power consumption Pi 24 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 22 kg / 48.5 lbs Standards IEC 60974-1, -3 and -10 CL.A Technical data Tetrix XQ 300 SiC puls AC/DC 8P

Version Tetrix XQ 300 SiC puls AC/DC Comfort 3.0 8POL Setting range for welding current 3 A - 300 A Duty cycle 40 °C 300 A / 40 % 270 A / 60 % 220 A / 100 % Open circuit voltage 87 V Mains voltage (ex works) 3 x 380 V - 400 V Mains tolerances (ex works) -25 % up to +20 % Mains frequency 50 Hz / 60 Hz Recommended generator power 15.3 kVA Efficiency 87 % Power consumption Pi 37 W Protection classification IP23 Test mark EMC class A Dimensions (L x B x H) 550 mm x 257 mm x 415 mm 21.7 inch x 10.1 inch x 16.3 inch Weight 22 kg / 48.5 lbs Standards IEC 60974-1, -3 and -10 CL.A

-

TIG DC Functions

Standard DC

Perfect TIG welding with ignition parameters adapted depending on power output.

Pulsed TIG DC welding

Decreases the heat input which reduces distortion and discolouration.

spotmatic

Triggers constant tack points only upon contact with the torch tip.

spotArc

Minimised time required for tacking and spot welding due to individual triggering of the tack points with the torch trigger.

activArc

Dynamic TIG arc with automatic arc stabilisation. The high arc force ensures a secure sidewall fusion and a targeted and uniform heat input. Particularly beneficial when welding fillet welds and root passes.

HF start

Prevents tungsten inclusions through non-contact arc ignition.

liftArc

Simple ignition of the arc without HF by pulling up the welding torch electrode after touching the workpiece.

TIG Antistick

Prevents damage to tungsten electrode in case of inadvertent contact with the workpiece.

TIG AC functions

Standard AC

Aluminium welding in just one click thanks to perfect presets. Easy adjustment of AC parameters for special applications.

Pulsed TIG DC welding

Reduced distortion and discolouration through energy per unit length and heat input.

AC balling

Ensures optimum tungsten balling and therefore a stable, easy-to-handle arc.

AC frequency

Adjustment of the arc force – ideal for thin metal sheets and fillet welds.

AC balance

Vary between more positive and more negative current proportion.

AC amplituden balance

Enables adjustment of negative and positive welding current.

AC waveforms

Optimum stability and reduced noise level thanks to adjustable AC waveforms (sine, trapezoidal, square and customised).

MMA functions

Standard MMA

Unlimited potential applications for electrode welding.

Hotstart

Prevents a lack of fusion at the start of the weld seam by briefly increasing the current when welding begins.

Arcforce

Adjustable arc dynamics from soft to hard.

Antistick

Prevents the electrode from annealing by briefly switching off the welding current.

Cel

100% reliable vertical-down welding with all cellulose electrodes.

MMA pulse welding

Vertical-up welding without using the “Christmas tree” technique, but still with reliable root fusion..

-

-

An overview of the Tetrix XQ series

TETRIX XQ puls DC

- / TIG

- / MMA

- / Standard DC

- / Pulsed TIG DC welding

- / spotmatic

- / spotArc

- / activArc

- / HF start

- / liftArc

- / TIG Antistick

TIG functions

- / Standard MMA

- / Hotstart

- / Arcforce

- / Antistick

- / Cel

- / MMA pulse welding

MMA functions

TETRIX XQ puls AC/DC

- / TIG

- / MMA

- / Standard DC

- / Pulsed TIG DC welding

- / spotmatic

- / spotArc

- / activArc

- / HF start

- / liftArc

- / TIG Antistick

- / Standard AC

- / Pulsed TIG welding

TIG functions

- / AC balling

- / AC frequency

- / AC balance

- / AC amplitude balance

- / AC waveforms

- / Standard MMA

- / Hotstart

- / Arcforce

- / Antistick

- / Cel

- / MMA pulse welding

MMA functions

IT MAKES YOU EVEN BETTER – the new TETRIX XQ modular

TETRIX XQ HAS ALL YOU NEED TO MAKE YOUR WELDING PERFECT.

WHATEVER YOU’RE PLANNING. Making every welding task fun.

Modular casing system for workstations in all kinds of environments. Gas- or water-cooled. DC or AC/DC. Flexible design: suitable for use both in production or as a mobile machine on the construction site or job. Portable or mobile on a trolley. Space-saving and lightweight design guarantees fl exibility and mobility.

EVERYTHING WITHIN REACH.

You can stow consumables in the storage compartment on the newly designed handle and always have them ready-to-go.

FULLY CONNECTABLE.

Your Tetrix XQ is outfitted with an interface for remote controls as standard. There’s also a 7-pole digital interface for your ewm Xnet welding management software.

ALWAYS IN SIGHT.

The large LED infobar with four unambiguous signal colours always shows you the current operating status of your TETRIX XQ.

PROTECTED CONNECTIONS.

To protect against damage, all connections are recessed into the casing, yet still conveniently accessible.

Protected control.

The protective cap protects against water, dirt and impact.

NO DISRUPTIVE AIR.

The new grille ensures that the airflow is diverted to below so that it doesn’t disrupt you or the welding process.

HIGHLY STURDY.

The completely new, robust machine feet also guarantee stability on uneven surfaces and protect against oil and salt water. They are perfectly suited for use in rough environmental conditions.

ORDERLINESS AROUND THE MACHINE.

The protruding frame on the side around the control can be used to coil up the welding torch and hose package to keep the machine neat, tidy, and safe.

Now it’s getting personal. The best controls for your best welding.

-

Expert 3.0You want perfect welding results, and that's exactly what you get. The Expert 3.0 control provides you with the ideal basis for this. It is available for all MIG/MAG-XQ welding machines and offers you an unrivalled level of intuitive operability. The possibilities for customising your welding experience are (almost) limitless. Experience welding at the highest level.

-

Comfort 3.0 DCThe Comfort 3.0 control unit impresses with its user-friendly and practice-oriented features. Two large, easy-to-read 7-segment displays ensure a clear presentation of all essential information. Five favorite buttons allow quick access to frequently used settings. Thanks to the ergonomic click-wheel, comfortable operation is guaranteed even when wearing welding gloves. In addition, the robust push-buttons provide reliable and precise control. All relevant functions are directly accessible. With Comfort 3.0, you always have all parameters in view – for efficient work and maximum control during welding.

-

Comfort 3.0 AC/DCThe Comfort 3.0 control unit impresses with its user-friendly and practice-oriented features. Two large, easy-to-read 7-segment displays ensure a clear presentation of all essential information. Five favorite buttons allow quick access to frequently used settings. Thanks to the ergonomic click-wheel, comfortable operation is guaranteed even when wearing welding gloves. In addition, the robust push-buttons provide reliable and precise control. All relevant functions are directly accessible. With Comfort 3.0, you always have all parameters in view – for efficient work and maximum control during welding.

Stay cool and clean, all the time.

THE NEW COOLING SYSTEM AND AIR DUCTING OF THE TETRIX XQ ENSURE TOP PERFORMANCE.

To keep your welding torch well cooled even under the heaviest loads, we developed the new COOL XQ cooling system. With excellent cooling capacity and integrated flow and temperature monitoring, it’s the perfect addition to your new TETRIX XQ. For those times when it takes a while. Air ducting of the TETRIX XQ operates in a targeted way, so only those parts which really need to be cooled are cooled. The sophisticated design minimises contamination, even in rough environments.

CAN BE USED WORLDWIDE.

In the multivolt version, the Tetrix XQ 230 puls with automatic adjustment of the mains voltage (110 - 120 V / 230 V) can only be combined with Cool XQ 40 MV.

Inside values.

- Need-based fan control

- Flow monitoring as standard

- Temperature monitoring as standard

- Powerful pump

Air escape on the side.

The air escape is located on the side of the cooler to prevent contamination from the workplace entering the machine – no interruptions, for you or the welding process.

SECURE WATER CONNECTION.

The water connections are recessed and optimally protected against damage.

Maintenance from the exterior.

Service-friendly design, e.g. access to centrifugal pump from exterior, without opening the casing.

FILLING LEVEL INDICATOR AND OPERATING INSTRUCTIONS DIRECTLY IN SIGHT.

You can easily check the filling level of the coolant from the indicator on the front, right next to the operating information.

DUST FILTERS. NOTHING GETS THROUGH.

The reusable stainless steel dust filter can be mounted without tools. It fits both your Cool XQ and your TETRIX XQ.

PERFECTLY POSITIONED CONNECTIONS.

The power and control connections are located on the top of the cooler, so it connects perfectly to the TETRIX XQ.

HIGHLY STURDY.

The completely new, robust machine feet ensure stability of the stand even on uneven ground which make it perfectly suited for use in rough environmental conditions.

Water outlet screw.

A water outlet screw is located on the front of the Cool XQ to make emptying the water tank easy, e.g. when cleaning the cooling circuit.

ewm Xnet

DIGITISE ANY WELDING OPERATION.

THE EWM XNET WELDING MANAGEMENT SYSTEM AND XBUTTON.

Better output for less money? Impossible? Or not!

Xnet digitises your welding operations, making it the perfect addition to your new TETRIX XQ. This future-oriented welding management system organises production, planning, quality management, welding coordination personnel and administration. In this way, it decisively helps you improve efficiency, quality and documentation. This is Welding 4.0 – and our answer to Industry 4.0.

XBUTTON – SMALL BUTTON. BIG EFFECT.

The Xbutton makes your TETRIX XQ even more reliable and a bit more “you”. You can easily transfer all the parameters from your personal welding plan and your specific menu settings to the machine.

Simply be more productive.

With ewm Xnet, you get more done in the same amount of time. Paperless transfer of all relevant data directly to the workplace, fewer error corrections thanks to specified welding parameters and less unnecessary downtime thanks to timely maintenance notices simply allow you to work more efficiently.

XQ Series Modular Accessories

XQ Series

DC or AC/DC? With or without cooling unit, site or workshop trolley?

You get exactly the Tetrix XQ you need for your welding tasks. As typical for EWM, the system is well thought out and every component is tested for tough everyday work.

Thanks to the variety of user-oriented accessories, the XQ series can be flexibly adapted to all challenges and applications.

DC

DC