Imagine this...

You’ve got the perfect solution for every welding task – in just one machine.

Titan XQ puls

Wishful thinking becomes reality.

That is exactly what you get with the Titan XQ puls from EWM: the latest RCC inverter technology and innovative EWM XQ welding processes included in your welding machine ex works and ready to use. Plus there are lots of other ways you can configure the Titan XQ puls to suit your needs.

Too good to be true?

Discover more...

Titan XQ puls – individually configurable

Titan XQ puls – a series of perfection. Individually configurable casing design for more flexibility thanks to a wide range of options. ...

Titan XQ puls decompact

With a wide range of options and accessories for the Drive XQ wire feeder, the 350 A, 400 A, 500 A and 600 A models (either gas or water cooled) can be adapted to all your requirements.

Titan XQ puls with double wire feeder

Customised design with and without a gas cylinder holder for one or two cylinders, mains cable length of up to 15 m, versions for two wire feeders and much more.

Titan XQ puls compact

with integrated eFeed wire feeder. In conjunction with the optional miniDrive intermediate drive, the action radius can be expanded to up to 30 m.

XQ - process

- Welding process finder

rootArc® XQ/rootArc® puls XQ

rootArc® XQ/rootArc® puls XQ coldArc® XQ/coldArc® puls XQ

coldArc® XQ/coldArc® puls XQ forceArc® XQ/forceArc® puls XQ

forceArc® XQ/forceArc® puls XQ wiredArc XQ/wiredArc puls XQ

wiredArc XQ/wiredArc puls XQ acArc puls XQ

acArc puls XQ Positionweld XQ

Positionweld XQ- TIG and MMA welding, gouging

- Pulse XQ/Standard XQ

Drive 4 XQ – great options to make life easier

Drive XQ wire feeder

At just 13 kg (excl. wire spool) and with a balanced, ergonomic handle, ... the Drive XQ wire feeder is the perfect companion for impassable scaffolding, hard-to-reach work spaces or large components – it can even fit through manholes.

-

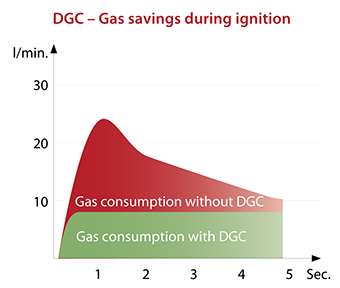

DGC – electronic gas flow control – save gas with ease and accuracy

- Prevents welding errors caused by too much or too little gas

- Efficiency through gas savings thanks to accurate settings

- Fully reproducible thanks to digital configuration and saving to the respective JOB (welding task) ...

- Constant gas flow rate thanks to electronic adjustment

- Nominal and actual value display of gas flow rate in l/min

- Extremely advantageous with long hose packages, e.g. for shipbuilding and steel construction

- No gas blast with turbulence when igniting the arc as electrical valve opens and closes gently

-

WRS – wire reserve sensor: no unexpected occurrences during welding

- The sensor warns at 10% residual quantity of the wire spool by means of a control lamp.

- It reduces the risk of seam errors occurring due to the wire running out during welding.

- A spool change can be planned in advance, which reduces downtime.

-

WHS – wire spool heater: regulated heat for better seam quality

- The wire is pre-heated, which reduces the build-up of moisture on the welding wire.

- The temperature is regulated at 50°C (adjustable).

- The welding results are perfect, especially for aluminium.

-

Electrode holder connection

- Ideal for MMA welding

- Ideal for gouging

eFeed wire feeder – full traction

-

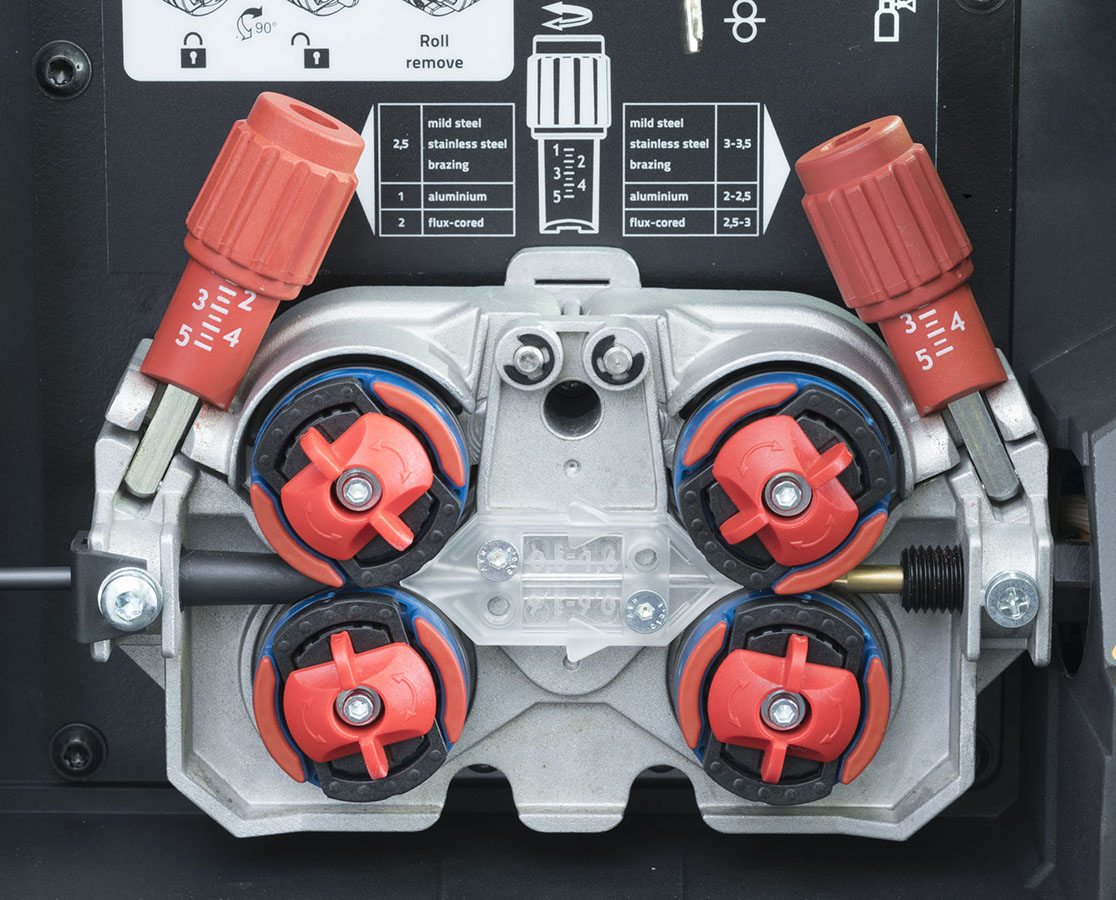

eFeed wire feeder with ball bearings and four driven drive rolls – one more step forward

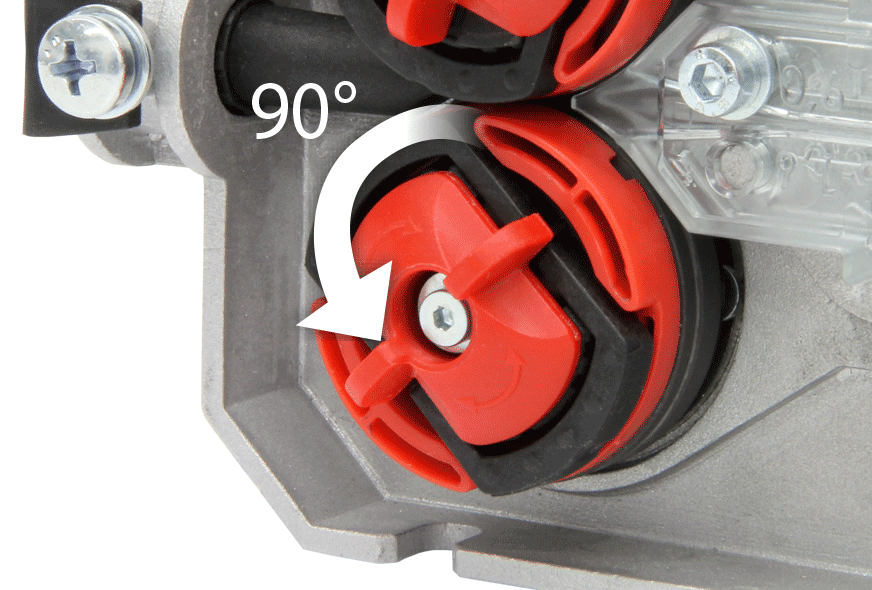

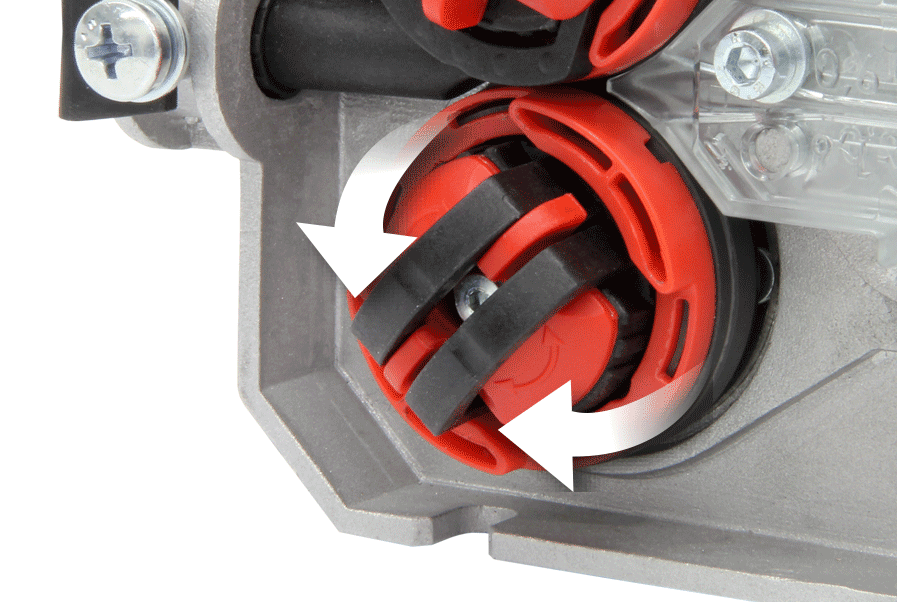

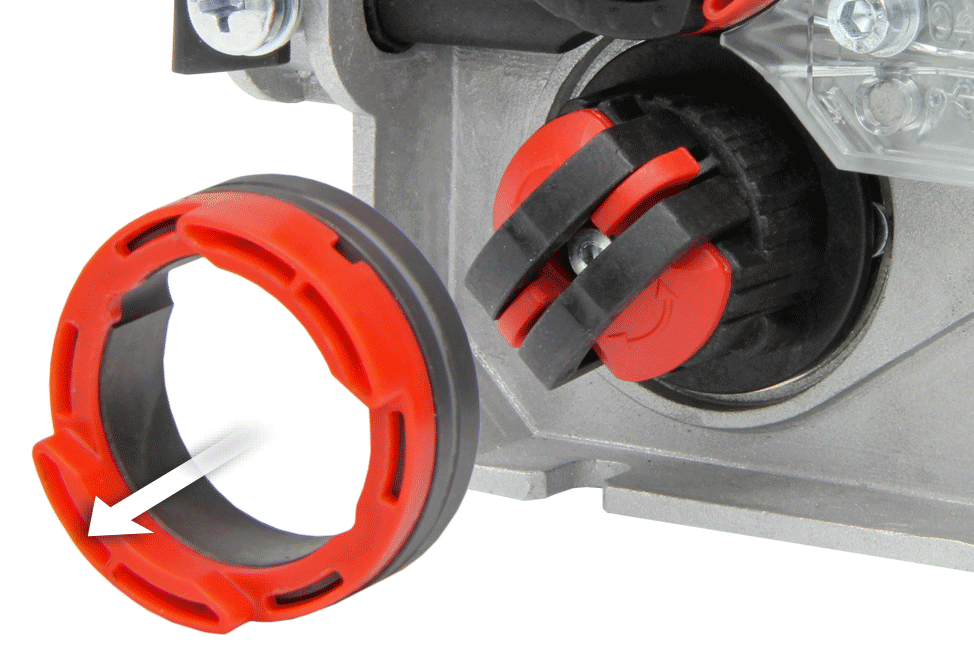

Exchange rolls in just three steps. Instantly, without tools and with captive parts

- Unlock the roll fastener

- Swivel out the captive roll fastener

- Exchange the roll

-

Colour-coded rolls – prevent confusion

The different groove diameters in the wire feed rolls are colour-coded. The grooves for aluminium (U-groove), steel, stainless steel and braze (V-groove) and flux cored wire (knurled) are indicated with coloured clips.

e.g. UNI rolls for Ø 1.0 mm to 1.2 mm with V-groove (blue/red) for stainless steel, steel

e.g. Ø 1 mm with U-groove (blue/yellow) for aluminium

e.g. Ø 1 mm with V-groove, knurled (blue/orange) for flux cored wire -

The eFeed wire feeder is accurate, durable and robust. The transfer is carried out cleanly via cogwheels housed in the high-quality aluminium die-cast casing. ... This improves the welding result even for flux cored wires and particularly soft or particularly hard, unmanageable wires.

4-wheel drive, the right way ... The four wire feed rolls are centrally driven by double ball bearing drive axles. Both this and the clean profile for different materials makes sure that precision is maintained even for particularly soft or particularly hard, unmanageable wires and flux cored wires.

Effective inching ... Wire inching takes place automatically and error-free with the eFeed. The casing can remain closed.

Quick roll changes ... The wire feed rolls can be changed quickly without tools: simply loosen the lock, open the bracket and remove the rolls. eFeed wire feeder with ball bearings and four driven drive rolls – one more step forward.

Titan XQ puls – control overview

-

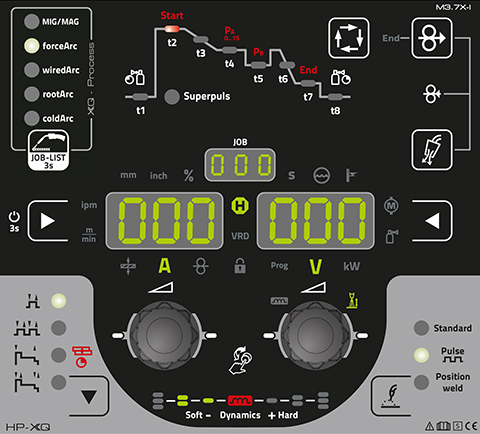

HP XQ

For perfectionists:

The HP-XQ control offers the highest level of requirement-specific setting options ... for the relevant welding task. The user can individually determine every detail of the welding sequence from the ignition current to the end crater program. The HP-XQ is the ideal control for professional users who leave nothing to chance for perfect results. -

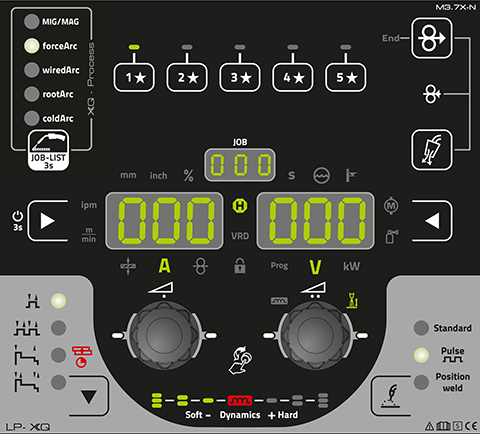

LP XQ

Turn it on and start welding:

Welders can use the favourites button to save their preferred settings ... and retrieve them. The LP-XQ control has the best parameters for the required welding sequence from the ignition current to the end crater program set up ex works. This saves training time: simply enter the operating point using the click wheel and start your work. The control is perfect for changing welding personnel, for example on construction sites and for assembly work. -

Expert XQ 2.0

Enjoy efficient working:

The Expert XQ 2.0 control shows what the machine offers. The user simply needs ... to select the welding procedure, material, gas and wire diameter using the click wheel. The appropriate characteristic for the welding task (JOB) is immediately shown on the robust and easy-to-read LCD display and the welder is ready to go.

The control is available in the following variants and network capabilities: Expert XQ 2.0, Expert XQ 2.0 LG with integrated LAN gateway and Expert XQ 2.0 WLG with integrated LAN/Wi-Fi gateway.

EWM professional welding torch: re-discover welding

Professional welding torch

Movement sensor, with motion-activated LED lighting, turns on automatically and ensures good visibility in dark work spaces (optional equipment) spaces (optional equipment)

-

Four operating variants – guaranteeing a good choice.

One standard torch and three function torches

are available for the Titan XQ. The modern two-component grip with its rubber anti-kink device and stable ball joint is a role model for ergonomic perfection and robust EWM quality. There are different operating concepts and display options. It’s your choice! -

RD3X function torch

Function torch with graphic display and LED light setting options:

- Welding current and wire feed speed

- Voltage correction

- Welding procedure

- Welding programs and tasks (JOBs)

- Operating mode (non-latched/latched)

- Component management

-

RD2X function torch

Function torch with graphic display and LED light setting options:

- Welding current and wire feed speed

- Voltage correction

- Welding programs

-

2U/DX function torch

MIG/MAG function torch

- Welding current and wire feed speed

- Voltage correction

- Program and JOB selection

-

Standard torch

Standard torch trigger for all MIG/MAG machines

Standard torch

Optional torch trigger on top

ewm Xnet 2.0

Welding 4.0 for large and small businesses. The modular system supports both welding coordination personnel and welders in their daily work.

Titan XQ puls options

Titan XQ

As you can expect from EWM, the system is well thought-out and each component tested under tough everyday conditions. Thanks to the extensive range of accessories, ... the welding machine can be customised to suit the individual needs of the welder and work environment.

The work radius can be expanded easily. Welding parameters can be changed from any location using a remote control. The optional brackets provide space for many components. The optional cooling unit with a reinforced pump ensures that the welding torch is cooled well even over long distances and height differences.

Wire feeder accessories

Drive XQ

For manual shielding gas flow setting, use in suspension operation ... or drum feeding: the Drive XQ wire feeder with its accompanying accessories can be easily customised for every user and every use.

Contact us!