Vocational students are being trained with ewm Xnet

Geschwister Scholl school uses EWM complete solution

Vocational students are being trained with ewm Xnet

Industry 4.0 is when people, machines and industrial processes connect intelligently. This is how the German Federal Ministry for Economic Affairs and Energy defines the fourth industrial revolution that is currently taking place in companies. The Geschwister Scholl school, a competence centre for business, care, social services and technology in Leutkirch, is preparing its students for this aspect of the future. To that end, Anton Netzer, technology instructor in the metal construction department, uses the Welding 4.0 solution by EWM AG in Mündersbach. It includes state-of-the-art welding machines and the digital quality management system for welding, ewm Xnet.

At Geschwister Scholl school in Leutkirch, a vocational competence centre for business, care, social services and technology, students are being prepared for a future with Industry 4.0. In recent years, the school has invested heavily in certain areas. Automotive mechanics trainees, for example, are working in a newly converted generous facility and with the latest technologies. In addition to the vehicle lifts, they now have an innovative testing station for driving assistance systems and high-voltage technology at their disposal. For the theoretical part of the training, smartboards are used.

Welding technology is already state of the art

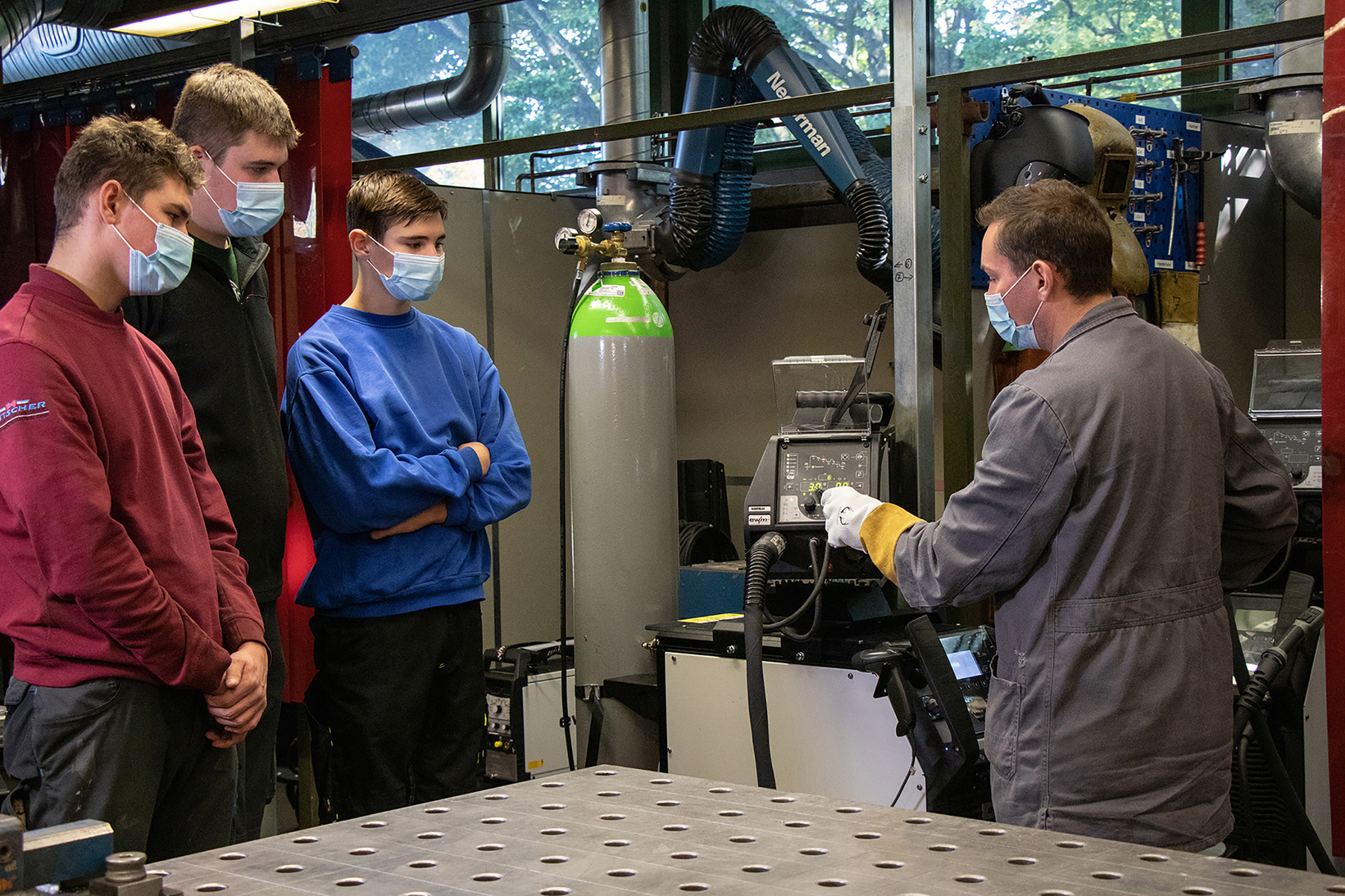

The metal construction department, where technology instructor Anton Netzer supervises 16 to 20 students, is now also being upgraded to Industry 4.0. Its facilities will be modernised in the coming months. The technical equipment of the nine welding booths has already been state of the art since the middle of 2020. The future construction mechanics and construction technicians training here are working with the EWM inverter welding machine Tetrix 230 for TIG and the Titan XQ puls for MIG/MAG and MMA. In addition, the multi-process welding machine provides the trainees directly with all the innovative XQ welding processes by EWM. “We want our students to learn the technologies that are offered in companies,” says Netzer. That’s how it is for metal construction trainee Jan Dullinger. He says, “We use EWM at work too. I can work quite well with the machines.” The new welding machines replace the step switch-controlled power sources the trainees used before to learn how to weld. The TIG machines are replacing the oxy-fuel welding process to a great extent.

Welding 4.0 with a complete system

Before investing in the machines, Anton Netzer, who as the technology instructor oversees selecting and purchasing machines, gathered comprehensive information. He knew exactly what he wanted: power sources that can handle all procedures, can be digitally linked and are ready for the future. “After all, technology keeps on evolving in the companies as well,” he explains. At the Blechexpo 2019 in Stuttgart, Anton Netzer first learned about Welding 4.0, the EWM complete welding system by Germany’s largest manufacturer for arc welding technology, and met Thomas Golz. During a visit to the school, the field service representative of EWM’s Tettnang plant assisted the metal construction department with planning and implementing an Industry 4.0 solution for training purposes.

All welding data in real time

Intelligently connecting people, machines and industrial processes: that’s exactly what EWM’s digital quality management system for welding can do. This software supports, documents and analyses a component’s entire production process, from work preparation to final costing, all completely paperless. ewm Xnet records all welding data in real time, manages it and communicates the consumption values on the connected monitors. In the process, the system recognises and signals parameter changes, which helps prevent errors, as Stanislav Wiens, Vice Head of Digital Welding Solutions at EWM, explains. He supports the Geschwister Scholl school with all questions about ewm Xnet. The system ensures that immersion of a tungsten electrode into the weld pool or insufficient penetration are always detected.

Weld seams can be analysed immediately

Anton Netzer takes advantage of these features for his training. He can see even while the students are working whether the weld seam is ok or not: “We can weld and then immediately look at the data together, analyse it and complete it. Where are the mistakes? Where is room for improvement? We don’t want to just make good weld seams. I want to make some bad weld seams with the students as well, so they know what’s important and how the work can be improved,” he explains and adds with a smile: “Students can’t do that in their companies, they want zero errors.”

How do I read a WPS?

Moreover, companies are more and more focused on complete documentation of weld seams in their own production for quality control and liability reasons. Students need to be prepared for this, too: how do I read and write a welding procedure specification (WPS), meaning a welding instruction that gives welders all the necessary parameters they need for a qualitatively perfect weld? Here again, Anton Netzer uses ewm Xnet to prepare his students. The integrated EN1090 WPQX package contains WPQR certificates and welding procedure specifications for the most used welding applications.

Questions are answered straightaway

Together with EWM field service representative Thomas Golz, an optimised practical complete solution was established for the school. Netzer is also very satisfied with EWM’s service: “I wanted a partner where I could ask questions after the purchase, guaranteed. EWM provides that guarantee,” Netzer happily explains.

For more information:

https://www.youtube.com/watch?v=9_S0RiJFL_U

Date: 10 November 2020

Volume: 5,664 characters including spaces

Figures: 6