- 我在这里:

-

首页

- 样板

CustomerStory

| Industry: | Steel construction |

| Material: | Unalloyed to high-alloy steels |

| Welding processes: | MAG forceArc puls |

| Keywords: |

Improved quality – increased competitiveness

The challenge:

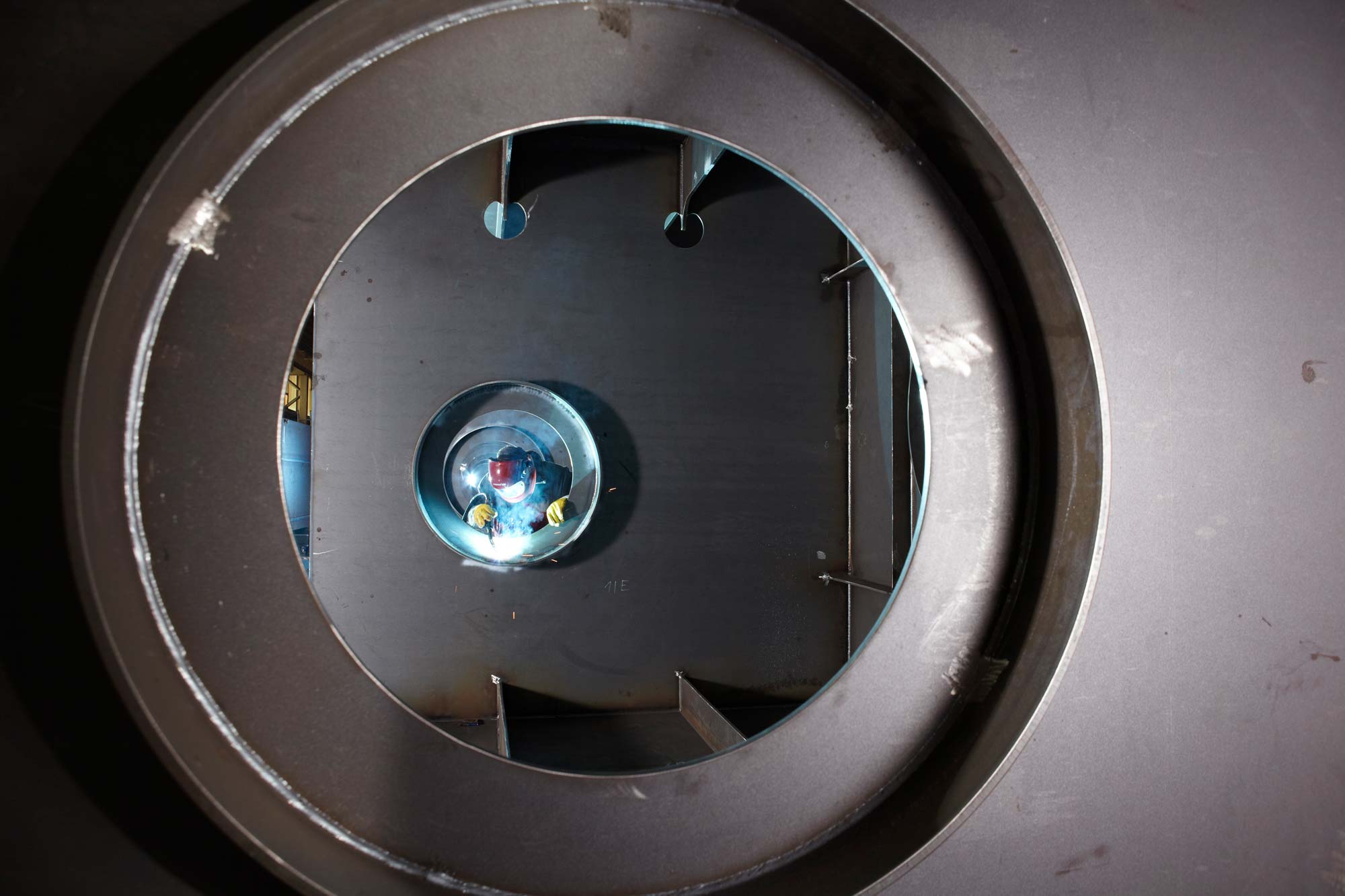

Plauen Stahl Technologie GmbH (PST) located in Vogtland in Germany works with large-volume components with individual parts weighing from 50 tonnes upwards on a daily basis. The components they handle include bridge segments such as those used for the Millau Viaduct in France, boiler support structures for power plants or floodgates with an enormous span. These kinds of constructions have the highest technical demands and safety and quality are extremely important. This is also true for extravagant architectural projects.

Plauen Stahl Technologie GmbH (PST) located in Vogtland in Germany works with large-volume components with individual parts weighing from 50 tonnes upwards on a daily basis. The components they handle include bridge segments such as those used for the Millau Viaduct in France, boiler support structures for power plants or floodgates with an enormous span. These kinds of constructions have the highest technical demands and safety and quality are extremely important. This is also true for extravagant architectural projects.

The solution:

The innovative forceArc welding process from EWM impressed PST senior employees with its welding results, boasting great binding properties with a deep penetration and excellent root and sidewall fusion. In addition, the forceArc also has some economic advantages: The reduced pre- and post-weld work and savings in wages, materials, gas and energy costs mean lower costs for the whole joining process, and all with increased productivity. PST welders also enjoyed working with the forceArc welding process.

The innovative forceArc welding process from EWM impressed PST senior employees with its welding results, boasting great binding properties with a deep penetration and excellent root and sidewall fusion. In addition, the forceArc also has some economic advantages: The reduced pre- and post-weld work and savings in wages, materials, gas and energy costs mean lower costs for the whole joining process, and all with increased productivity. PST welders also enjoyed working with the forceArc welding process.

The success:

In the past, PST welded sections over 500 millimetres using submerged arc welding. Today, sections up to 800 millimetres and material thicknesses up to 80 millimetres are joined using the forceArc process, significantly reducing setup time. Non-productive times when welding single-bevel groove seams could be considerably lowered by using forceArc, as this would require only minimal cleaning and gouging work. Excess weld metal on the root can be reached safely and its appearance controlled with definition. In this process, the excess weld metal on the root creates a fillet weld with a specified concave fillet, corresponding overlap and the required throat thickness.

In the past, PST welded sections over 500 millimetres using submerged arc welding. Today, sections up to 800 millimetres and material thicknesses up to 80 millimetres are joined using the forceArc process, significantly reducing setup time. Non-productive times when welding single-bevel groove seams could be considerably lowered by using forceArc, as this would require only minimal cleaning and gouging work. Excess weld metal on the root can be reached safely and its appearance controlled with definition. In this process, the excess weld metal on the root creates a fillet weld with a specified concave fillet, corresponding overlap and the required throat thickness.