- Sei qui:

-

Home

- Referenze

Relazione pratica

| Settore: | Costruzione di veicoli |

| Materiale: | Acciaio |

| Procedimenti di saldatura: | Saldatura MAG |

| Parole chiave: | Xnet, Saldatura MAG, Taurus, Nutzfahrzeuge, LKW-Achse, Pendelachse, Xbutton, |

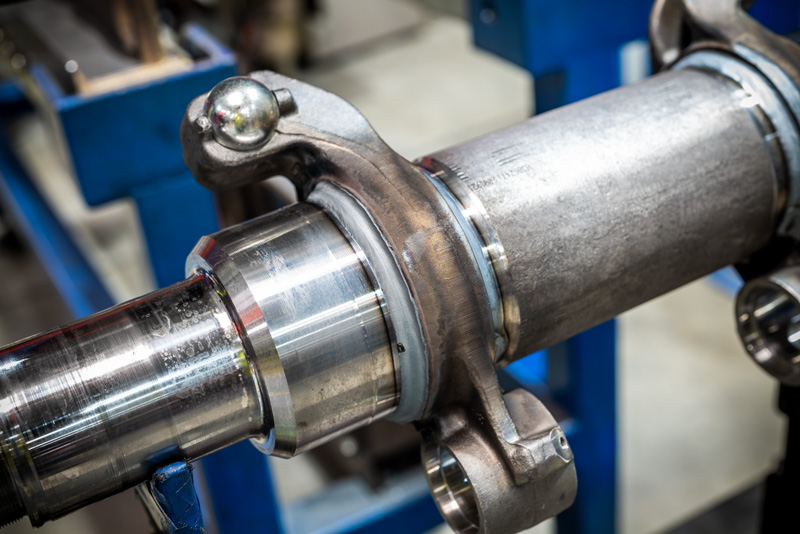

Chassis axles designed to carry huge axle loads represent a major challenge in the quality assurance process. This is why SAF-Holland relies on…

La situazione iniziale:

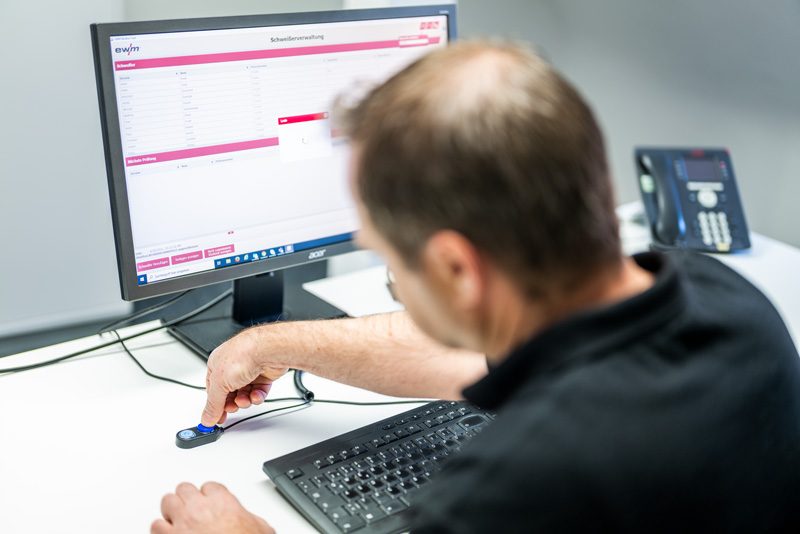

SAF-Holland has fully adopted the zero-defect strategy. When it comes to welding processes, this strategy ensures that every weld seam is created using exactly the right welding parameters – every single time. This is easy to verify when using automated and robotic processes, as these parameters are subject to continuous automatic monitoring. It’s more difficult with manual welding. This is where the welding management system ewm Xnet comes in.

SAF-Holland has fully adopted the zero-defect strategy. When it comes to welding processes, this strategy ensures that every weld seam is created using exactly the right welding parameters – every single time. This is easy to verify when using automated and robotic processes, as these parameters are subject to continuous automatic monitoring. It’s more difficult with manual welding. This is where the welding management system ewm Xnet comes in.

La soluzione:

ewm Xnet works continuously to record and store every welding parameter during the manual welding process, allowing them to be accessed and checked whenever necessary. If the welding parameters are within certain predefined tolerances, then the welding result is of the required quality. In order to achieve a clear allocation between the welding parameters and the component, every single component at SAF-Holland receives a unique dot-peened serial number as well as a QR code. This ensures that the component is clearly defined and allows all parameters to be assigned to it.

ewm Xnet works continuously to record and store every welding parameter during the manual welding process, allowing them to be accessed and checked whenever necessary. If the welding parameters are within certain predefined tolerances, then the welding result is of the required quality. In order to achieve a clear allocation between the welding parameters and the component, every single component at SAF-Holland receives a unique dot-peened serial number as well as a QR code. This ensures that the component is clearly defined and allows all parameters to be assigned to it.

Il successo:

This makes the welder’s job a lot easier, and choosing incorrect welding parameters is impossible. Before welding, the welder scans the component’s serial number. They then hold the Xbutton in front of the welding machine. The Xbutton is an RFID chip in which the welding coordination personnel preset the relevant parameters and tolerances. Wrong choices of settings are avoided thanks to the welding parameters being allocated to components on the Xbutton. This is because the welder only has access to the preset parameters. An essential component of the zero-defect strategy.

This makes the welder’s job a lot easier, and choosing incorrect welding parameters is impossible. Before welding, the welder scans the component’s serial number. They then hold the Xbutton in front of the welding machine. The Xbutton is an RFID chip in which the welding coordination personnel preset the relevant parameters and tolerances. Wrong choices of settings are avoided thanks to the welding parameters being allocated to components on the Xbutton. This is because the welder only has access to the preset parameters. An essential component of the zero-defect strategy.