- Olet tässä:

-

Etusivu

- Referenssi

Array

(

[0] => stdClass Object

(

[id] => 38

[catid] => 57

[name] => Stadler Winterthur AG

[alias] => stadler-winterthur-ag

[customer] => Stadler Winterthur AG

[customer_logo] => images/referenzen/logos_schienen/stadler_blue_rgb_png.png

[titelbild] => images/referenzen/sliderbilder/stadler_L211977_web.jpg

[sectorId] => COM_EWMREFERENCE_SCHIENENBAU

[materialId] => ["COM_EWMREFERENCE_STAHL"]

[processId] => ["COM_EWMREFERENCE_MIG_MAG","COM_EWMREFERENCE_WIG_SCHWEISSEN"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => How Stadler in Winterthur is optimising bogie production

with EWM technology

[benefit_subtext] => Groundbreaking e_ ciency in the manufacture of rail vehicles – Stadler Rail places high demands on the welding process in production. When manufacturing bogies,

it is not only cost-effectiveness and process reliability that are important, but above all precision and high weld seam quality.

EWM masters these challenges with welding machines that impress with their intuitive operation, digital interfaces and reliable performance in daily shift operation.

[teaser] => Groundbreaking e_ ciency in the manufacture of rail vehicles – Stadler Rail places high demands on the welding process in production. When manufacturing bogies,

it is not only cost-effectiveness and process reliability that are important, but above all precision and high weld seam quality.

EWM masters these challenges with welding machines that impress with their intuitive operation, digital interfaces and reliable performance in daily shift operation.

[casestudy_status] => Stadler Winterthur AG is the centre of excellence for bogies within the Stadler Rail Group. Its focus is on precision, cost-effectiveness and process reliability. The complex assemblies are manufactured in two shifts by over 120 welders using a high degree of automation. In addition to the required weld seam quality and reproducibility, the demands on digital welding data management are also growing. In order to ensure quality in the long term and standardise processes, Stadler decided to switch to EWM welding equipment and to use only machines from one manufacturer.

[casestudy_solution] => Since 2024, Stadler Winterthur AG has been relying on welding technology from EWM: over 80 welding machines are in use, including the Titan XQ 400 for MAG welding and the Tetrix XQ 300 for TIG welding. Both systems impress with their intuitive operation, ergonomic functional torches with integrated displays and robust performance in shift operation. The ewm Xnet digital welding management system centrally records, evaluates and documents all process data. This allows quality and efficiency to be monitored and continuously improved in real time.

[casestudy_effectiv] => The switch to EWM welding technology went smoothly and was quickly accepted by employees. The simple handling and clear menu navigation make it easier to train new welders and significantly reduce the error rate. Existing components could continue to be used, which further accelerated integration. Today, Stadler Winterthur AG benefits from more stable production, greater process reliability and a sustainable increase in manufacturing quality – a decisive step towards a future-proof welding process in rail vehicle construction.

[documents] => {"doc_name":["PraxisReport DE","PraxisReport EN"],"doc_link":["Stadler_Rail_CH_DE_201025_FIN_02.pdf","Stadler_Rail_CH_EN_201025_FIN_02.pdf"],"description":["PraxisReport DE","PraxisReport EN"]}

[imageslider] => {"image_link":["stadler_L211940_web.jpg","stadler_L211977_web.jpg","stadler_L211987_web.jpg","stadler_L212046_web.jpg","stadler_L212065_web.jpg"],"description":["Bild 1","Bild 2","Bild 3","Bild 4","Bild 5"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 37

[access] => 1

[language] => *

[params] =>

[created] => 2025-12-03 11:06:09

[created_by] => 590

[created_by_alias] =>

[modified] => 2026-01-06 05:58:23

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 5

[hits] => 0

)

[1] => stdClass Object

(

[id] => 37

[catid] => 67

[name] => WAAM3D

[alias] => waam3d

[customer] => WAAM3D

[customer_logo] => images/referenzen/logos_luft/WAAM.png

[titelbild] => images/referenzen/sliderbilder/WAAM_Bild2.png

[sectorId] => COM_EWMREFERENCE_SONSTIGE

[materialId] => ["COM_EWMREFERENCE_METALL","COM_EWMREFERENCE_STAHL"]

[processId] => ["COM_EWMREFERENCE_WAAM"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Precise welding technology for additive manufacturing

[benefit_subtext] => Wire Arc Additive Manufacturing (WAAM) has experienced a significant upswing in recent years. This advanced technology allows complex metal structures to be manufactured efficiently and precisely. The British company WAAM3D, a pioneer in the field of WAAM technology, works with EWM welding equipment to produce high-quality metal components for various industries such as aerospace, energy and shipping.

[teaser] => Wire Arc Additive Manufacturing (WAAM) has experienced a significant upswing in recent years. This advanced technology allows complex metal structures to be manufactured efficiently and precisely. The British company WAAM3D, a pioneer in the field of WAAM technology, works with EWM welding equipment to produce high-quality metal components for various industries such as aerospace, energy and shipping.

[casestudy_status] => Wire additive manufacturing (WAAM) offers enormous opportunities, but also presents companies with special challenges. In order to reliably build complex metal structures, the welding systems used must operate with absolute precision and stability over many hours. For WAAM3D, it was therefore clear that a solution had to be found that would ensure uniform layer formation, high repeatability and consistent quality, even during long manufacturing processes.

[casestudy_solution] => The choice fell on plasma welding systems from EWM. With the Tetrix 352 and 552 models, WAAM3D can precisely control the process parameters and thus ensure controlled, reproducible material application. The high duty cycle and flexibility in the use of different materials make the devices the ideal solution for the special requirements of WAAM technology. In addition, the power sources can be easily integrated into WAAM3D's existing automation systems, enabling a consistently efficient and robust production process.

[casestudy_effectiv] => By using EWM welding technology, WAAM3D has been able to significantly increase process reliability and stability. Welding errors, especially with demanding materials such as titanium or Inconel, are reliably avoided. The company benefits from consistently high component quality and can guarantee its customers reliable and reproducible results. In addition to the technical advantages, WAAM3D also values its close cooperation with EWM: fast support, expert advice and the certainty of being well equipped for the future development of the technology.

[documents] => {"doc_name":["PraxisReport DE","PraxisReport EN"],"doc_link":["WAAM_T4_DE_040825_FIN.pdf","WAAM_T4_EN_230725_FIN.pdf"],"description":["PraxisReport DE","PraxisReport EN"]}

[imageslider] => {"image_link":["WAAM_Bild1.jpg","WAAM_Bild2.png","WAAM_PTA-Part_web.jpg","WAAM_T1_web.jpg","WAAM_T2_web.jpg"],"description":["WAAM3D_Bild1","WAAM3D_Bild2","WAAM3D_Bild3","WAAM3D_Bild4","WAAM3D_Bild4"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 36

[access] => 1

[language] => *

[params] =>

[created] => 2025-10-06 09:50:46

[created_by] => 604

[created_by_alias] =>

[modified] => 2025-10-07 08:20:19

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 11

[hits] => 0

)

[2] => stdClass Object

(

[id] => 36

[catid] => 67

[name] => TANICS

[alias] => tanics

[customer] => TANICS™

[customer_logo] => images/referenzen/logos_sonst/Tanics_Blue_AW.png

[titelbild] => images/referenzen/sliderbilder/tanicsIMG_0313.jpg

[sectorId] => COM_EWMREFERENCE_NUR

[materialId] => [""]

[processId] => ["COM_EWMREFERENCE_FORCE_TIG"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => When radioactive materials need to be safely enclosed in containers,

every detail counts

[benefit_subtext] => especially the weld seam. With

TANICS™ R-TIG, a robot-assisted welding system for nuclear

applications, and the forceTig® high-performance TIG process

from EWM, a new solution has been developed speci_ cally for

this challenge: It automates the entire welding process, thereby

protecting personnel from radiation exposure and not only

o_ ers absolute process reliability, but also delivers reproducible

seam quality at the highest level.

[teaser] => When radioactive materials need to be safely enclosed in containers,

every detail counts - especially the weld seam. With

TANICS™ R-TIG, a robot-assisted welding system for nuclear

applications, and the forceTig® high-performance TIG process

from EWM, a new solution has been developed speci_ cally for

this challenge: It automates the entire welding process, thereby

protecting personnel from radiation exposure and not only

o_ ers absolute process reliability, but also delivers reproducible

seam quality at the highest level.

[casestudy_status] => Lifelong and absolutely secure sealing is a top priority when it comes to transporting and storing highly radioactive material in specially manufactured stainless steel containers. No one is allowed to be near the welding process when the containers with the nuclear material inside are being sealed. The protection of personnel and absolute process reliability are paramount, so reliable and automated welding solutions are essential. In collaboration with TANICS™, the joint venture between Amentum and Langfields Ltd., we have therefore developed TANICS™ R-TIG.

[casestudy_solution] => TANICS™ R-TIG is a robot-assisted welding system that, in combination with EWM's high-performance forceTig® TIG welding process, meets the highest standards of quality, safety and flexibility in accordance with PD5500 Category 1 and Sellafield Build Level specifications. Different container sizes and seam geometries can be reliably welded – directly on site, fully automated and remote-controlled. Cameras mounted directly on the robot and an integrated inspection system enable the weld seam to be viewed from different angles and ensure seamless quality control.

[casestudy_effectiv] => Reproducibility of seam quality, process reliability and personnel protection. The specifications at the start of the collaboration were clear. And it is precisely at the point where conventional TIG welding reaches its limits that the newly developed TANICS™ R-TIG solution comes into play. It is a practical response to the challenges faced by the nuclear industry and other sectors, meets the strict standards of European norms and is ASME-qualified. TANICS™ R-TIG provides optimum protection for personnel in hazardous environments and ensures the highest weld seam quality at all times.

[documents] => {"doc_name":["PraxisReport DE","PraxisReport EN"],"doc_link":["053-000281-00000_Tanics_310725_DE.pdf","053-000281-00001_Tanics_310725_EN.pdf"],"description":["PraxisReport DE","PraxisReport EN"]}

[imageslider] => {"image_link":["tanics1.png","tanics2.png","tanics3.png","tanicsDSC_0825.jpg","tanicsDSC_7146.jpg","tanicsIMG_0313.jpg"],"description":["Tanics","Tanics2","Tanics2","Tanics4","Tanics5","Tanics6"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 35

[access] => 1

[language] => *

[params] =>

[created] => 2025-08-19 09:50:01

[created_by] => 591

[created_by_alias] =>

[modified] => 2025-08-19 10:48:36

[modified_by] => 591

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 8

[hits] => 0

)

[3] => stdClass Object

(

[id] => 35

[catid] => 57

[name] => alwitra GmbH

[alias] => alwitra-gmbh

[customer] => alwitra GmbH

[customer_logo] => images/referenzen/logos_sonst/ALWITRA.jpg

[titelbild] => images/referenzen/sliderbilder/EWM-React-bei-Alwitra-Trier-022.jpg

[sectorId] => COM_EWMREFERENCE_SONSTIGE

[materialId] => [""]

[processId] => ["COM_EWMREFERENCE_REACT"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Efficient and automated welding with EWM React

[benefit_subtext] => Quality, efficiency and process optimisation. The demands in the manufacturing industry are constantly increasing and require the use of innovative welding technologies. For this reason, alwitra GmbH, a leading provider of system solutions for flat roofs, relies on EWM React. Almost all of the products used for the more than 175 million square metres of sealed roof surfaces per year have to be welded. It is often not only the functionality of the weld seams that counts, but also their appearance. With EWM React, alwitra secures a decisive competitive advantage.

[teaser] => Quality, efficiency and process optimisation. The demands in the manufacturing industry are constantly increasing and require the use of innovative welding technologies. For this reason, alwitra GmbH, a leading provider of system solutions for flat roofs, relies on EWM React. Almost all of the products used for the more than 175 million square metres of sealed roof surfaces per year have to be welded. It is often not only the functionality of the weld seams that counts, but also their appearance. With EWM React, alwitra secures a decisive competitive advantage.

[casestudy_status] => In the past, alwitra used a standard pulse MIG process to manufacture components. The level of automation in the company was rather low at around 30%, as special products made up the majority of production. However, there is great potential for optimisation, particularly in the production of standard components, as increasing automation can further improve quality and reduce costs. alwitra is constantly adapting its product range to current market requirements and is therefore all the more dependent on the use of innovative welding technology.

[casestudy_solution] => Process stability plays an important role for alwitra when using welding robots. This is where EWM React comes into play as an automation solution, as the welding process is the ideal combination of short arc and digital welding process control. Combined with a highly dynamic torch drive, the result is a precise and reliable automation process that delivers perfect welds. EWM React gives the user full control over the droplet transfer and, with the process variants Speed, Positionweld and superPulse, offers tailor-made solutions for even the most demanding welding tasks.

[casestudy_effectiv] => The objective of the cooperation between alwitra and EWM was clearly defined: Automated welding was to take productivity to a new level. This is exactly what has been achieved with EWM React, as the high deposition rates of the spray arc range have been combined with all the advantages of the short arc. Hardly any spatter, minimal distortion, enormous process stability and a reduction in heat input of up to 35% - these advantages speak for themselves. With alwitra, the result is a time saving of more than one minute per workpiece - both during welding and in post-processing.

[documents] => {"doc_name":["PraxisReport DE","PraxisReport EN"],"doc_link":["053-000272-00000_alwitra.pdf","053-000272-00001_alwitra.pdf"],"description":["PraxisReport DE","PraxisReport EN"]}

[imageslider] => {"image_link":["EWM-React-bei-Alwitra-Trier-022.jpg","EWM-React-bei-Alwitra-Trier-023.jpg","EWM-React-bei-Alwitra-Trier-027.jpg","EWM-React-bei-Alwitra-Trier-032.jpg","EWM-React-bei-Alwitra-Trier-033.jpg","EWM-React-bei-Alwitra-Trier-039.jpg","EWM-React-bei-Alwitra-Trier-042.jpg"],"description":["Alwitra_1","Alwitra_2","Alwitra_3","Alwitra_4","Alwitra_5","Alwitra_6","Alwitra_7"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 34

[access] => 1

[language] => *

[params] =>

[created] => 2024-11-15 06:47:36

[created_by] => 590

[created_by_alias] =>

[modified] => 2024-11-15 07:30:28

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 7

[hits] => 0

)

[4] => stdClass Object

(

[id] => 34

[catid] => 57

[name] => Nordic Steel AS

[alias] => nordic-steel-as

[customer] => Nordic Steel AS

[customer_logo] => images/referenzen/logos_sonst/LogoNordicSteel_WithSlogan_231x31.png

[titelbild] => images/referenzen/sliderbilder/NordicSteel4.jpg

[sectorId] => COM_EWMREFERENCE_STAHLBAU

[materialId] => ["COM_EWMREFERENCE_STAHL"]

[processId] => ["COM_EWMREFERENCE_MIG_MAG","COM_EWMREFERENCE_WIG_SCHWEISSEN"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => EWM enhances environmental commitment at Nordic Steel

[benefit_subtext] => Nordic Steel AS is a leading company in the steel industry and a comprehensive provider of mechanical production solutions. The company has firmly positioned itself as a driving force not only in Norway, but also on a global level. The extensive reference list includes major players from a wide range of industries, such as renewable energy, oil and gas, aquaculture, maritime, HVAC, transport, infrastructure, construction, piping, defence, aerospace, and various other sectors. Nordic Steel has strong and long-lasting partnerships in all these sectors, making it a full-service provider.

[teaser] => Nordic Steel AS is a leading company in the steel industry and a comprehensive provider of mechanical production solutions. The company has firmly positioned itself as a driving force not only in Norway, but also on a global level. The extensive reference list includes major players from a wide range of industries, such as renewable energy, oil and gas, aquaculture, maritime, HVAC, transport, infrastructure, construction, piping, defence, aerospace, and various other sectors. Nordic Steel has strong and long-lasting partnerships in all these sectors, making it a full-service provider.

[casestudy_status] => Nordic Steel AS has been using welding machines from EWM for many years. However, before the strategic partnership between them began, the Norwegian company had problems with various other welding machines. These occurred particularly when welding aluminium, which led to rapid downtimes throughout the welding operation. After analysing the situation in detail, Nordic Steel AS decided to work with EWM in 2010. Since then, the efficiency and quality of the entire welding operation has increased significantly.

[casestudy_solution] => Every welding task is different for the Norwegian full-service provider from the steel industry and with the welding machines from EWM, Nordic Steel is ideally prepared for a wide range of conditions. There are now 26 welding machines at the Bryne site, which are very well suited for aluminium welding thanks to the built-in position welding function and effectively reduce downtimes. In addition, the experience of the company's welders confirms that the machines are user-friendly, produce perfect weld seams and have a robust design.

[casestudy_effectiv] => A central component of Nordic Steel's corporate philosophy is its outstanding commitment to the environment. High standards for top performance and sustainability apply throughout the entire welding operation and are maintained using EWM welding equipment. This is ensured, among other things, by the resource-saving inverter technology and the energy-efficient welding processes. Nordic Steel has been recognised as the most environmentally friendly steelworks in Norway, and its status as an industry pioneer with a strong environmental focus was recognised in 2021 with the "Miljøfyrtårn" (Environmental Lighthouse) award.

[documents] => {"doc_name":["PraxisReport DE","PraxisReport EN"],"doc_link":["053-000246_00000_Praxisreport_NordicSteel_DE.pdf","053-000246_00001_Praxisreport_NordicSteel_EN.pdf"],"description":["PraxisReport DE","PraxisReport EN"]}

[imageslider] => {"image_link":["NordicSteel4.jpg","NordicSteelDSC_3067.jpg","NordicSteelDSC_3109.jpg","NordicSteelDSC_3118.jpg","NordicSteelSvein.jpg","NordicSteelwelder-on-stairs.jpg","NordicSteelwelder-table.jpg","NordicSteelworkbench.jpg"],"description":["Bild 1","Bild 2","Bild 3","Bild 4","Bild 5","Bild 6","Bild 7","Bild 8"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 33

[access] => 1

[language] => *

[params] =>

[created] => 2024-07-17 11:55:42

[created_by] => 590

[created_by_alias] =>

[modified] => 2024-07-17 11:57:34

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 3

[hits] => 0

)

[5] => stdClass Object

(

[id] => 33

[catid] => 57

[name] => Bilfinger SE

[alias] => bilfinger-se

[customer] => Bilfinger SE

[customer_logo] => images/referenzen/logos_sonst/bilfinger-logo.png

[titelbild] => images/referenzen/sliderbilder/Bilfinger_Noell_superconducting-magnets-bn_190731_11865.jpg

[sectorId] => COM_EWMREFERENCE_NUR

[materialId] => [""]

[processId] => ["COM_EWMREFERENCE_MIG_MAG"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

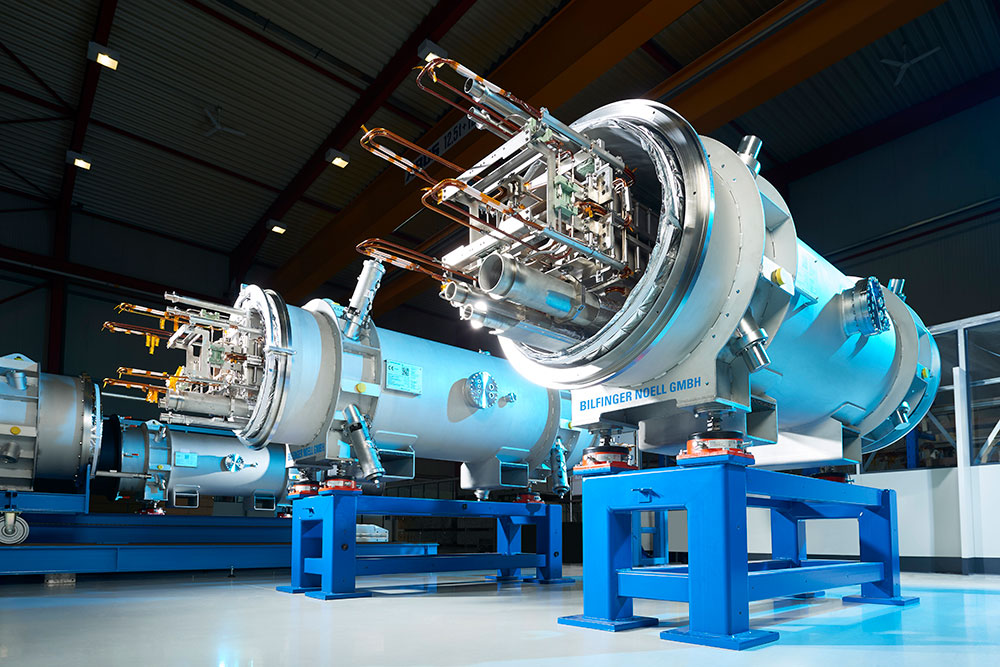

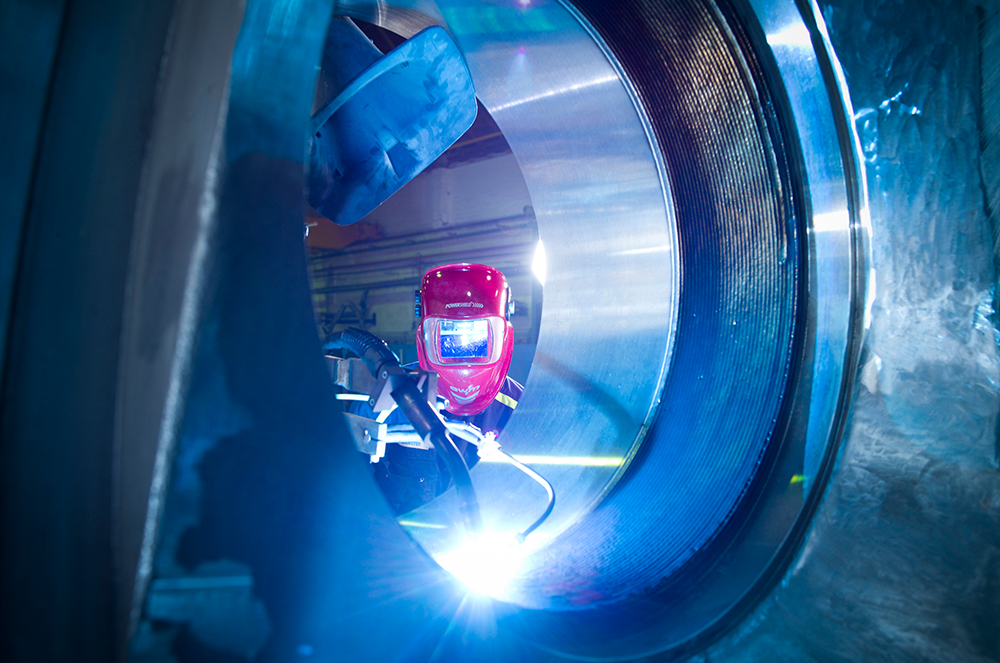

[benefit_headline] => Documentation down to seam level

[benefit_subtext] => Traceability and documentation are typical buzzwords, especially when it comes to certified components. Who welded which seam with which parameters and when? All this data is necessary to comply with the obligatory documentation requirements – an obligation that is often perceived as too time-consuming. ewm Xnet provides a remedy and supports welding coordinators and welders in their daily work – as well as doing so much more.

[teaser] => As a nuclear and magnet technology specialist, Bilfinger Noell is certified in accordance with DIN EN 10190 in the highest execution class EXC 4 – with special obligatory documentation.

[casestudy_status] => This documentation often involves huge sheets of paper with extensive tables that are shuffled back and forth between the welding coordination personnel's office and production at the welding site. Welders transfer the welding parameters and the coordinator countersigns them. But it’s so easy to make a writing error when transferring the welding parameters to the paper table. And is it really stored in such a way that it can be retrieved at any time? After all, the worst-case scenario for any welding coordination personnel is when something happens but the relevant documents are not available.

[casestudy_solution] => ewm Xnet brings together everything you need for the documentation. It starts with the relevant WPS. In addition to the parameters, the welding sequence can also be defined. When it comes to welding, the welder logs on via Xnet. This also fulfils the documentation requirements. The barcode assigned to each weld seam is used to set the correct parameters on the machine straight away. This ensures quality that can be proven. All data can be found at any time and can also be analysed afterwards – completely tamper-free.

[casestudy_effectiv] => The introduction of ewm Xnet changes everything in the daily work of a welding coordinator – but at the same time doesn’t really change anything at all. After all, ewm Xnet does not change the work itself. It simply makes work simpler, safer and more efficient. Secure and fast access to all data and the associated documents is a great help, especially during audits and in the event of a warranty claim. The additional recording of consumption data also gives users an idea of actual capacity and costs of the respective projects. The bottom line: weak points can be uncovered quickly and potential utilised.

[documents] => {"doc_name":["PraxisReport DE","PraxisReport EN"],"doc_link":["052-000232-00000_Praxisreport_Bilfinger_Noll_GmbH.pdf","052-000232-00001_Praxisreport_Bilfinger_Noll_GmbH.pdf"],"description":["PraxisReport DE","PraxisReport EN"]}

[imageslider] => {"image_link":["Bilfinger_Noell_Hot-Cell_KB18274.jpg","Bilfinger_Noell_Schleusen-bn_1803012261.jpg","Bilfinger_Noell_Sge-Rckbau_NPP_ret_DSC8492.jpg","Bilfinger_Noell_superconducting-magnets-bn_190731_11865.jpg","Bilfinger_ANSTO_KKF8004_b_fin_lr.jpg","Bilfinger_Bilder.jpg","Bilfinger_Bilder2.jpg","Bilfinger_Bilder4.jpg","Bilfinger_Bilder6.jpg","Bilfinger_Bilder9.jpg"],"description":["Bilfinger_1","Bilfinger_2","Bilfinger_3","Bilfinger_4","Bilfinger_5","Bilfinger_6","Bilfinger_7","Bilfinger_8","Bilfinger_9","Bilfinger_10"]}

[links] => {"doc_name":["YouTube"],"doc_link":["https://www.youtube.com/watch?v=5ir_qQvN95A"],"description":["Als Nuklear- und Magnettechnik-Spezialist ist Bilfinger Noell nach DIN EN 10190 in der höchsten Ausführungsklasse EXC 4 zertifiziert – mit besonderen Anforderungen an die Dokumentationspflicht."]}

[article_id] => 0

[ordering] => 32

[access] => 1

[language] => *

[params] =>

[created] => 2024-04-04 11:08:58

[created_by] => 590

[created_by_alias] =>

[modified] => 2024-04-04 11:19:24

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 3

[hits] => 0

)

[6] => stdClass Object

(

[id] => 32

[catid] => 57

[name] => SBS Kft Hungary

[alias] => sbs-kft-ungarn

[customer] => SBS Kft

[customer_logo] => images/referenzen/logos_sonst/sbs_logo_rgb.png

[titelbild] => images/referenzen/SBS_3.jpg

[sectorId] => COM_EWMREFERENCE_LOHNFERTIGER

[materialId] => ["COM_EWMREFERENCE_VERSCHIEDENES"]

[processId] => ["COM_EWMREFERENCE_FORCE_ARC","COM_EWMREFERENCE_FORCE_ARC"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

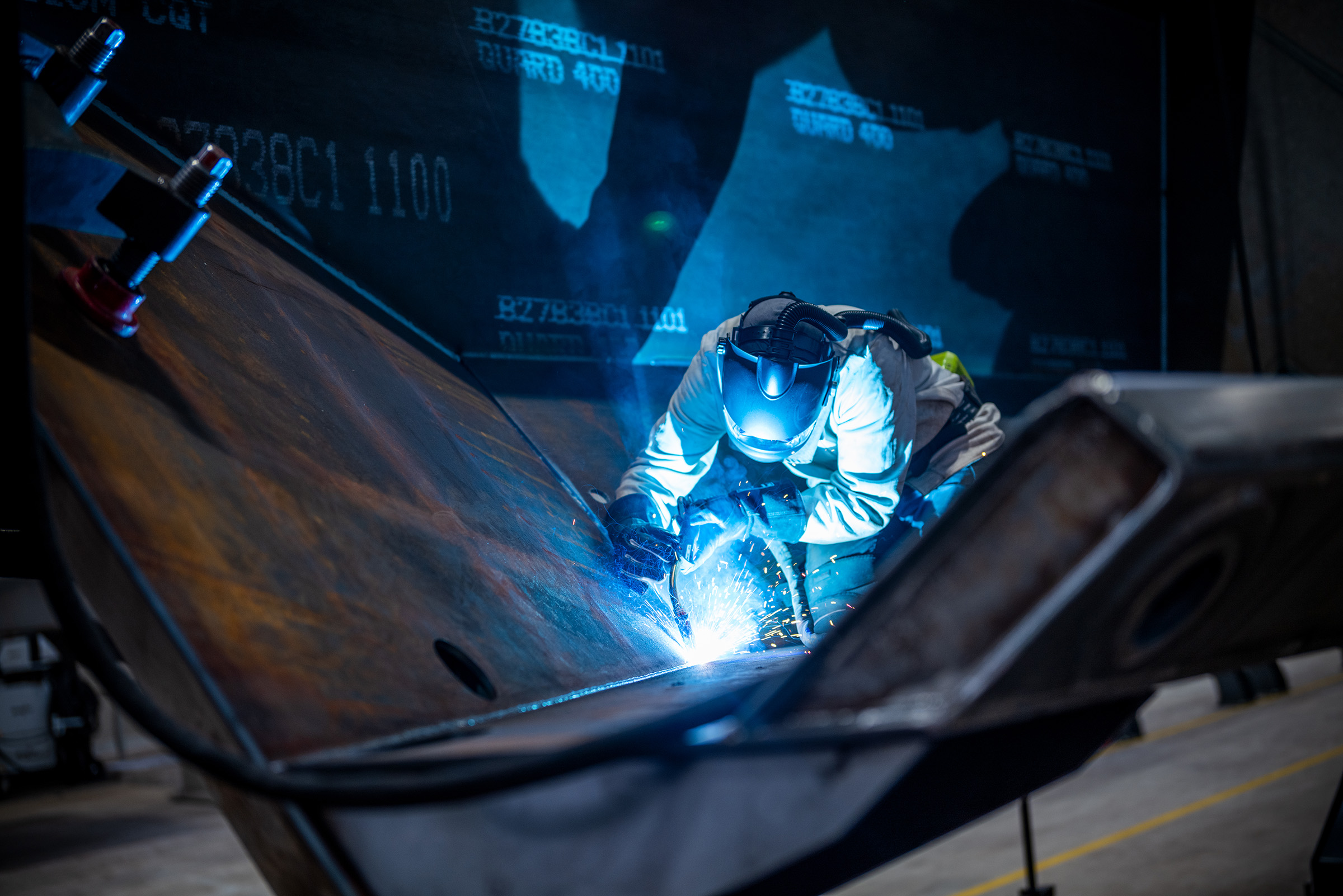

[benefit_headline] => A brief look at contract manufacturer SBS Kft Hungary.

[benefit_subtext] => Higher welding quality with a significant reduction in the time required for both welding itself

and finishing work – this sums up contract manufacturer SBS Kft., based in Erdőtelek, Hungary

around 130 km east of Budapest. Thanks to a

greater arc penetration depth, the new forceArc

welding process results in significant time savings alongside an increase in welding quality.

Another benefit is that EWM welding machines

require far fewer spare and wear parts despite a

higher duty cycle. All these effects lead to an increase in productivity.

[teaser] => Higher welding quality with a significant reduction in the time required for both welding itself

and finishing work – this sums up contract manufacturer SBS Kft., based in Erdőtelek, Hungary

around 130 km east of Budapest. Thanks to a

greater arc penetration depth, the new forceArc

welding process results in significant time savings alongside an increase in welding quality.

Another benefit is that EWM welding machines

require far fewer spare and wear parts despite a

higher duty cycle. All these effects lead to an increase in productivity.

[casestudy_status] => Increasing quality requirements and greater cost

pressure are the challenges faced by most contract

manufacturing companies. In the case of welding,

this is synonymous with high welding quality produced in less time. Only through this combination

can a true productivity advantage be achieved.

The spectrum begins with selection of the welding

procedure and can also include design measures.

This was precisely the challenge faced by SBS Kft.

[casestudy_solution] => If a weld seam can be welded from just one side

instead of both, it saves a lot of time – both in

terms of handling and the welding process itself.

This substantial change to the workflow is possible thanks to the innovative forceArc welding

process from EWM. ForceArc is a heat-minimised

pulsed arc with both great penetration depth and

outstanding gap bridging. This makes it possible

to weld the carbon steels being used in a reliable

way with nearly no spatter, yet with the same outstanding welding quality and considerably less finishing work

[casestudy_effectiv] => SBS Kft. were so impressed by the quality and long

duty cycle of the Taurus welding machines from

EWM that they procured 20 welding machines in

a single order and equipped their welding shop

with them. In addition to improving quality, the

company are able to reduce costs thanks to both

a significant reduction in finishing work and a considerable decrease in the number of consumables

used – all the parts used last much longer than

they used to (wear parts in particular).

[documents] => {"doc_name":["PraxisReport_DE","PraxisReport_EN"],"doc_link":["053-000215-00000_SBS_Ungarn.pdf","053-000215-00001_SBS_Ungarn.pdf"],"description":["PraxisReport_DE","PraxisReport_EN"]}

[imageslider] => {"image_link":["SBS_2.jpg","SBS_3.jpg","SBS_4.jpg"],"description":["SBS_2","SBS_3","SBS_4"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 31

[access] => 1

[language] => *

[params] =>

[created] => 2023-09-21 06:02:05

[created_by] => 590

[created_by_alias] =>

[modified] => 2023-10-24 05:58:14

[modified_by] => 595

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 6

[hits] => 0

)

[7] => stdClass Object

(

[id] => 31

[catid] => 67

[name] => Dražice

[alias] => drazice

[customer] => Dražice

[customer_logo] => images/referenzen/logos_sonst/Logo_drazice.jpg

[titelbild] => images/referenzen/drazice_1_web.jpg

[sectorId] => COM_EWMREFERENCE_SONSTIGE

[materialId] => [""]

[processId] => [""]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Hot water storage tanks and water heaters (boilers)

[benefit_subtext] => Dražice started with the idea of manufacturing the most economical and least failure-prone water heater ever – in short: the best boiler. This became the company’s philosophy. Despite achieving its targets every year, the company continues to optimise its products. This continuous improvement of the quality of their water heaters (boilers), buffer tanks and heating elements has been recognised with various awards, such as the AOVT 2021 Award and the Czech Business Superbrands 2022.

[teaser] => Dražice is the Czech Republic’s leading manufacturer of hot water storage tanks and water heaters.

[casestudy_status] => The Dražice portfolio includes over 380 types or modifications of hot water storage tanks and water heaters as well as various types of buffer tank. The basic structure of the tanks is always similar: A sheet is shaped into a pipe and the seam is welded. A base and lid are then added and also radially welded. It is important to have high-quality seams which will withstand the pressure in the heat accumulators later on.

[casestudy_solution] => The base material for the heat accumulator is structural steel with a yield strength of 230 MPa; the diameters of the pipes range between 500 and 850 mm; the material thickness is between 2 and 3 mm. Each component requires individualised weld seams. With the wide range of welding machines and innovative welding processes, EWM machines always deliver optimal results. What’s more, the control of the welding machines can be easily integrated into Dražice’s plant controls, allowing automated or semi-automated production of the base bodies.

[casestudy_effectiv] => Depending on the application, the Titan XQ 400 puls DW or the Picomig 355 puls is used for automated welding, as they provide the right welding parameters for any material, even aluminium. In manual welding, the Phoenix 405 Progress puls stands out with its wide range of applications, from MIG/MAG to electrode all the way to TIG welding. The drive 4X wire feeder feeds the filler metal safely to the weld spot. This results in almost spatter-free seams, high weld seam quality and minimal post weld work, because for Dražice, reliable weld seams mean high productivity and thus strong performance.

[documents] => {"doc_name":[" PraxisReport_DE"," PraxisReport_EN"],"doc_link":["053-000203-00000_Druzstevni_zavody_Drazice.pdf","053-000203-00001_Druzstevni_zavody_Drazice.pdf"],"description":[" PraxisReport_DE"," PraxisReport_EN"]}

[imageslider] => {"image_link":["drazice_1_web.jpg","drazice_2_web.jpg","drazice_3_web.jpg","drazice_4_web.jpg"],"description":["Drazice_1","Drazice_2","Drazice_3","Drazice_4"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 30

[access] => 1

[language] => *

[params] =>

[created] => 2022-11-10 10:50:58

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-11-15 14:40:12

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 2

[hits] => 0

)

[8] => stdClass Object

(

[id] => 30

[catid] => 67

[name] => BRS Motorsport

[alias] => brs-motorsport

[customer] => BRS Motorsport

[customer_logo] => images/referenzen/logos_sonst/logo_motorsport.png

[titelbild] => images/referenzen/motorsport_titel_web.jpg

[sectorId] => COM_EWMREFERENCE_SONSTIGE

[materialId] => [""]

[processId] => [""]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Formula Student: students build racing car

[benefit_subtext] => Formula Student is an international engineering competition for students. To take part in the competition, each team designs, constructs and manufactures a small formula racing car and also participates in international competitions with it. This gives students a chance to build on their theoretical knowledge from their studies with practical experience in construction and production as well as learn about the economical aspects of the industry.

[teaser] => Every year, BRS Motorsport e. V. develops and manufactures a spectacular electric racing car ...

[casestudy_status] => BRS Motorsport e. V. is a coalition of students that take part in the international Formula Student competition every year. From design and construction all the way to production – the team completed yet another spectacular electric racing car this year. Students are supported by a wide range of industry partners from across all different sectors in their quest to produce innovative vehicles.

[casestudy_solution] => The chassis is a full carbon monocoque constructed using no steel or aluminium welded constructions. To protect the driver’s body and legs in the event the car rolls over or is involved in an accident, the car has a “large” roll bar (main hoop) and a “small” roll bar (front hoop). These are welded constructions made from steel pipes and aluminium square pipes. The aluminium in particular poses a challenge when it comes to the welding procedure and can only be welded safely using high-quality welding machines and suitable welding processes.

[casestudy_effectiv] => Following a training session by EWM application engineers, the students used both the Picomig 305 and Tetrix 230 AC/DC welding machines to weld the individual components on their own. This also included the battery container, a welded construction made from aluminium sheet. Various victories in the electric vehicle class are testament to the club’s high-quality and innovative work.

[documents] => {"doc_name":["PraxisReport_DE","PraxisReport_EN"],"doc_link":["053-000202-00000_BRS_Motorsport_v3.pdf","053-000202-00001_BRS_Motorsport_v3.pdf"],"description":["PraxisReport_DE","PraxisReport_EN"]}

[imageslider] => {"image_link":["motorsport_titel_web.jpg","motorsport_web.jpg","motorsport_2_web.jpg","motorsport_3_web.jpg"],"description":["Motorsport_Titel","Motorsport_1","Motorsport_2","Motorsport_3"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 29

[access] => 1

[language] => *

[params] =>

[created] => 2022-11-10 10:28:51

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-11-10 10:32:12

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 2

[hits] => 0

)

[9] => stdClass Object

(

[id] => 29

[catid] => 57

[name] => Finsterle GmbH

[alias] => finsterle-gmbh

[customer] => Finsterle GmbH

[customer_logo] => images/referenzen/logos_sonst/Logo_Finsterle.png

[titelbild] => images/referenzen/finsterle_L1530728.jpg

[sectorId] => COM_EWMREFERENCE_SONSTIGE

[materialId] => ["COM_EWMREFERENCE_STAHL","COM_EWMREFERENCE_MAT_SONSTIGE"]

[processId] => ["COM_EWMREFERENCE_MAG_SCHWEISSEN"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Overcoming the challenges of automated welding with fine-grained steels

[benefit_subtext] => Welding without crack formation. Welders need to be able to weld without cracks forming when joining (weight-bearing) steel components made from fine-grained steels. Preheating the corresponding component reduces thermal stress. Finsterle GmbH’s task for EWM was to automate this step. Developers at our Sales and Technology Centre in Neu-Ulm quickly came up with the basic framework: the system is designed using two separate robot welding cells, each with a positioner, and an integrated preheating unit.

[teaser] => Welding without crack formation. Welders need to be able to weld without cracks forming when joining (weight-bearing) steel components made from fine-grained steels. Preheating the corresponding component reduces thermal stress. Finsterle GmbH’s task for EWM was to automate this step. Developers at our Sales and Technology Centre in Neu-Ulm quickly came up with the basic framework: the system is designed using two separate robot welding cells, each with a positioner, and an integrated preheating unit.

[casestudy_status] => As a toll manufacturer, flexibility is absolutely crucial for Finsterle GmbH. Ultimately, nobody can predict what orders customers will approach the metal construction company with – neither in terms of the application nor in terms of the components. A robot system with two welding cells, each with a positioner, is the perfect base concept. Clamped components are accessible from both sides and the robot can easily reach them. However, previous systems have been purely robot welding solutions without any consideration for a preheating unit.

[casestudy_solution] => The robot arm is equipped with a pneumatically operated tool changer and can be used to hold all kinds of tools. The oxyacetylene torch and the welding torch are located on different sides of the welding booth to avoid any hoses getting in the way during operation. First, the gripper takes hold of the oxyacetylene torch. This is ignited at an external ignition station. Once the base temperature of the component has been sufficiently increased, the oxyacetylene torch is placed in the parking position. The gripper then grabs the welding torch to start welding the steel components.

[casestudy_effectiv] => The automated system for Finsterle GmbH is the first solution of its kind. An automated welding process has previously never been designed for this material due to the required preheating for fine-grained steels. This development is particularly interesting for components with large batch sizes. But Finsterle’s automated solution isn’t just a win from a production standpoint. In times of skilled worker shortages, the new robotic welding system also means the company is now better equipped to face the future challenges of the labour market.

[documents] => {"doc_name":["PraxisReport_DE","PraxisReport_EN"],"doc_link":["053-000198-00000_PraxisReport_Finsterle.pdf","053-000198-00001_PraxisReport_Finsterle.pdf"],"description":["PraxisReport_DE","PraxisReport_EN"]}

[imageslider] => {"image_link":["finsterle_L1530728.jpg","finsterle_A1260906.jpg","finsterle_A1260941.jpg","finsterle_A1260956.jpg","finsterle_L1530688.jpg","finsterle_L1530756.jpg","finsterle_L1530774.jpg"],"description":["Finsterle_01","Finsterle_02","Finsterle_03","Finsterle_04","Finsterle_05","Finsterle_06","Finsterle_07"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 28

[access] => 1

[language] => *

[params] =>

[created] => 2022-09-06 10:48:17

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-09-06 10:48:17

[modified_by] => 0

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 1

[hits] => 0

)

[10] => stdClass Object

(

[id] => 28

[catid] => 70

[name] => Vogelsang GmbH & Co. KG

[alias] => vogelsang-gmbh-co-kg

[customer] => Vogelsang GmbH & Co. KG

[customer_logo] => images/referenzen/logos_sonst/logo-vogelsang.png

[titelbild] => images/referenzen/Auswahl_DSC_0916_TN_RET_web.jpg

[sectorId] => COM_EWMREFERENCE_ANLAGEBAU

[materialId] => ["COM_EWMREFERENCE_UN_HOCHLEGIERT"]

[processId] => ["COM_EWMREFERENCE_WIG_SCHWEISSEN"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => The user-friendly way to process all kinds of material thicknesses

[benefit_subtext] => The user-friendly way to process all kinds of material thicknesses

With ten new MIG/MAG XQ welding machines, the company was able to quickly establish welding sites in line with the state of the art.

The result: significantly reduced rework and even more efficient welding processes in the company.

[teaser] => The user-friendly way to process all kinds of material thicknesses

With ten new MIG/MAG XQ welding machines, the company was able to quickly establish welding sites in line with the state of the art.

The result: significantly reduced rework and even more efficient welding processes in the company.

[casestudy_status] => With its machines, the Essen-Oldenburg-based company focuses on the waste management, abattoir, fishing and agricultural sectors. Almost all of its products involve welding work on a wide range of materials, including unalloyed and low-alloy construction steels or chrome-nickel steels with various material thicknesses. This diverse spectrum of work is bolstered by Vogelsang’s high degree of vertical integration. With such a wide range of materials and material thicknesses, the company has high demands for ist welding machines.

[casestudy_solution] => In 2021, the company quickly settled on EWM’s new XQ series. Vogelsang was immediately blown away by what was possible with the new power sources, noting in particular how user-friendly the machines were. The saved JOBs for different materials and material thicknesses were a particular highlight for the company, offering potential to significantly simplify work sequences. These allow the welder to load optimised, pre-programmed machine settings for every task.

[casestudy_effectiv] => The new XQ machines and their processes allow the company to work with extremely low spatter. They also significantly reduce the amount of post-weld work required. In just a few weeks, the positive effects of the XQ welding machines on energy and material consumption will also be clear to see. The machine users were also impressed: they wanted to replace all welding machines with the MIG/MAG XQ series as soon as the first machines were commissioned.

[documents] => {"doc_name":["PraxisReport_DE","PraxisReport_EN"],"doc_link":["053-000187-00000_2022_06_Praxisreport_Vogelsang_V2.pdf","053-000187-00001_2022_06_Praxisreport_Vogelsang_V2.pdf"],"description":["PraxisReport_DE","PraxisReport_EN"]}

[imageslider] => {"image_link":["Auswahl_DSC_0882_TN_RET_web.jpg","Auswahl_DSC_0885_TN_todoRetusche.JPG","Auswahl_DSC_0898_TN_todoRetusche.JPG","Auswahl_DSC_0907_TN_RET_web.jpg","Auswahl_DSC_0916_TN_RET_web.jpg"],"description":["Vogelsang_Bild 1","Vogelsang_Bild 2","Vogelsang_Bild 3","Vogelsang_Bild 4","Vogelsang_Bild 5"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 27

[access] => 1

[language] => *

[params] =>

[created] => 2022-07-15 07:46:58

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-07-15 07:46:58

[modified_by] => 0

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 1

[hits] => 0

)

[11] => stdClass Object

(

[id] => 27

[catid] => 57

[name] => MST Parts Group

[alias] => mst-parts-group

[customer] => MST Parts Group

[customer_logo] => images/referenzen/logos_sonst/MST_logo.jpg

[titelbild] => images/referenzen/MST.jpg

[sectorId] => COM_EWMREFERENCE_SONSTIGE

[materialId] => ["COM_EWMREFERENCE_STAHL","COM_EWMREFERENCE_BAUSTAHL_HOCHFEST_STAEHLE"]

[processId] => [""]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => MST/Hi-Spec Manufacturing manufactures the largest dredger buckets...

[benefit_subtext] => The dredger buckets of earthmoving and mining machines have one job: to pick up and move large quantities of heavy rock and stone. It almost goes without saying that the materials used on these machines need to be incredibly wear-resistant and repairs are just part and parcel of the work involved. That’s where the UK-based MST Parts Group comes in as one of the international market leaders in the manufacturing of the world’s largest dredger buckets and their related repairs.

[teaser] => The dredger buckets of earthmoving and mining machines have one job: to pick up and move large quantities of heavy rock and stone. It almost goes without saying that the materials used on these machines need to be incredibly wear-resistant and repairs are just part and parcel of the work involved. That’s where the UK-based MST Parts Group comes in as one of the international market leaders in the manufacturing of the world’s largest dredger buckets and their related repairs.

[casestudy_status] => One cubic metre of natural rock weighs around two tonnes – an MST bucket can carry up to five cubic metres without even breaking a sweat. Of course, this can be particularly demanding on the dredger and its power, as well as the bucket itself. The use of wear-resistant steels as a material choice and for the welding consumables is common...

[casestudy_solution] => From welding machines and a wide variety of welding consumables to bespoke welding torches – EWM’s extensive range makes it the perfect partner for MST Parts Group. To ensure successful repairs, material quality is fundamental when it comes to processing wear-resistant steels such as S355, Weldox and all Hardox materials...

[casestudy_effectiv] => It’s not just MST’s customers who are thrilled with the welding results. The EWM products’ reliability was quickly noticed by MST, too. Thanks to their robust design, EWM products mean no more repair invoices for welding machines...

[documents] => {"doc_name":["...aus der Praxis DE","...Inpractice EN"],"doc_link":["053-000185-00000_Kurzreferenz_MST.pdf","053-000185-00001_Kurzreferenz_MST.pdf"],"description":["...aus der Praxis DE","...Inpractice EN"]}

[imageslider] => {"image_link":["MST.jpg","MST_2.jpg","MST_3.jpg"],"description":["Groß. Schwer. Robust.","Nick Fagandini, Direktor für Schaufeln (links), Lewis Barnes, Funktion (Mitte) und\nAlan Barnes, Betriebsleiter (rechts) in dem größten jemals im Vereinigten Königreich\ngebauten Hochlöffel PC8000.","Die Siebschaufel hat ein Volumen von 25 m³ und wird für die Gewinnung von Gestein\nam Meeresboden verwendet, wobei der Schlick zurückbleibt."]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 26

[access] => 1

[language] => *

[params] =>

[created] => 2022-05-11 05:03:22

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-05-11 05:31:51

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 5

[hits] => 0

)

[12] => stdClass Object

(

[id] => 26

[catid] => 57

[name] => IGEFA WEINBRENNER Energy Solutions GmbH

[alias] => igefa-weinbrenner-energy-solutions-gmbh

[customer] => IGEFA WEINBRENNER Energy Solutions GmbH

[customer_logo] => images/referenzen/logos_lebens/igefa-logo.png

[titelbild] => images/referenzen/IGEFA.jpg

[sectorId] => COM_EWMREFERENCE_LEBENSMITTEL

[materialId] => [""]

[processId] => ["COM_EWMREFERENCE_COLD_ARC","COM_EWMREFERENCE_MAG_SCHWEISSEN"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Skilled worker shortages, full order books and high quality standards

[benefit_subtext] => Heat exchangers made by Hof-based company, IGEFA WEINBRENNER Energy Solutions GmbH in the Westerwald region of Germany, are used across many different sectors, from the food, brewing and beverage industry and energy/chemical sector, all the way to the pulp and paper industry. And, just like the production and industrial systems used in these sectors, the heat exchangers used also have to be tailored to the needs of the industry. When it comes to constructing and designing these systems, the use of special materials is just as important as continuous data collection for the purposes of quality assurance.

[teaser] => Heat exchangers made by Hof-based company, IGEFA WEINBRENNER Energy Solutions GmbH in the Westerwald region of Germany, are used across many different sectors, from the food, brewing and beverage industry and energy/chemical sector, all the way to the pulp and paper industry. And, just like the production and industrial systems used in these sectors, the heat exchangers used also have to be tailored to the needs of the industry. When it comes to constructing and designing these systems, the use of special materials is just as important as continuous data collection for the purposes of quality assurance.

[casestudy_status] => Many sectors and companies are currently faced with a challenging combination of skilled worker shortages, full order books and high quality standards to maintain, making efficient and safe processes that ensure optimum use of the given resources all the more important...

[casestudy_solution] => IGEFA WEINBRENNER Energy Solutions GmbH successfully implemented a line of EWM welding machines in the area of TIG welding. As part of the planned switchover within welding production, it also made sense to take a closer look at EWM machines for MAG welding, too...

[casestudy_effectiv] => Choosing the right welding procedure can significantly decrease the amount of post weld work needed and subsequently increase productivity. The increased weld seam quality in the root pass and the reduction in overall welding times both play a part here. That means a more efficient component production...

[documents] => {"doc_name":["...aus der Praxis DE","...Inpractice EN"],"doc_link":["053-000186-00000_Kurzreferenz_IGEFA.pdf","053-000186-00001_Kurzreferenz_IGEFA.pdf"],"description":["...aus der Praxis DE","...Inpractice EN"]}

[imageslider] => {"image_link":["IGEFA.jpg"],"description":["Bild 1"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 25

[access] => 1

[language] => *

[params] =>

[created] => 2022-05-11 04:48:34

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-05-11 05:32:48

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 5

[hits] => 0

)

[13] => stdClass Object

(

[id] => 25

[catid] => 58

[name] => Hüffermann Transportsysteme GmbH

[alias] => hueffermann-transportsysteme-gmbh

[customer] => Hüffermann Transportsysteme GmbH

[customer_logo] => images/referenzen/hueffermann/logo_hueffermann.png

[titelbild] => images/referenzen/A1410075-Montage-retusche.jpg

[sectorId] => COM_EWMREFERENCE_FAHRZEUGBAU

[materialId] => ["COM_EWMREFERENCE_STAHL"]

[processId] => ["COM_EWMREFERENCE_MAG_FORCE_ARC"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => 300 weld seams in 90 minutes

[benefit_subtext] => It was primarily a shortage of skilled workers that motivated Hüffermann Transportsysteme GmbH to break new ground in chassis production. The lorry trailer manufacturer based in Neustadt (Dosse) in the Brandenburg region of Germany now manufactures 16 skeletal and container trailers using the EWM-Euen system every week, almost doubling its production while reducing manpower.

[teaser] => It was primarily a shortage of skilled workers that motivated Hüffermann Transportsysteme GmbH to break new ground in chassis production. The lorry trailer manufacturer based in Neustadt (Dosse) in the Brandenburg region of Germany now manufactures 16 skeletal and container trailers using the EWM-Euen system every week, almost doubling its production while reducing manpower.

[casestudy_status] => The clamping for manual welding of the 7-metre-long components was rather basic. Precise alignment of the longitudinal beams and other components is, however, fundamental for high-quality lorry trailers. That’s why the clamping was planned in such a way as to ensure that the components remained aligned and in position. The integrated longitudinal axis of rotation also improves accessibility, allowing almost all seams to be welded in the flat position. However, a question was raised during the planning of the clamping device: “Why not automate the welding process too?”

[casestudy_solution] => The automation system had to be planned with consideration of circumstances such as the hall structure, clamping device and space conditions. The gantry system with a welding robot on the gantry consists of two separate working areas. The shared sliding door closes one section at a time and the robot can weld while the open side is being loaded. The welding machine, a Phoenix puls, is situated near the partition. The drive 4X wire feeder is situated directly above the drums with the welding consumable and conveys the wire via the cable drag chain (which also carries electricity and gas) to the robot. forceArc puls is the only welding process used. The arc is powerful and deeply penetrates the material. At the same time, the heat input is reduced by the pulsing.

[casestudy_effectiv] => The plant produces 16 skeletal trailers every week with four welders. The welders are mainly charged with loading and tack welding the individual components and assemblies. The actual welding is done by the robots. This has resulted not only in faster welding but also increased quality. Continuous monitoring of the welding parameters in automated welding ensures high-quality weld seams at all times. As the process also produces very little spatter, the post weld work is reduced by 30 per cent and productivity is increased.

[documents] => {"doc_name":["PraxisReport DE","PraxisReport EN"],"doc_link":["053-000182-00000_Hueffermann_Automatisierung.pdf","053-000182-00001_Hueffermann_Automatisierung.pdf"],"description":["PraxisReport DE","PraxisReport EN"]}

[imageslider] => {"image_link":["A1410075-Montage-retusche.jpg","A1410052-montage.jpg","A1410102.jpg","A1410117.jpg","L1360019-retusche-test.jpg"],"description":["Bild_Hueffermann_1","Bild_Hueffermann_2","Bild_Hueffermann_3","Bild_Hueffermann_4","Bild_Hueffermann_5"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 24

[access] => 1

[language] => *

[params] =>

[created] => 2022-03-17 11:56:08

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-03-17 11:58:06

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 3

[hits] => 0

)

[14] => stdClass Object

(

[id] => 24

[catid] => 57

[name] => Schroeder Valves GmbH & Co. KG

[alias] => schroeder-valves-gmbh-co-kg

[customer] => Schroeder Valves GmbH & Co. KG

[customer_logo] => images/featured/logo_schroeder-valves.png

[titelbild] => images/referenzen/Weichpanzerung_Ventilkoerper-Automatisierung_web.jpg

[sectorId] => COM_EWMREFERENCE_SONSTIGE

[materialId] => ["COM_EWMREFERENCE_SCHWARZ_EDEL"]

[processId] => ["COM_EWMREFERENCE_ALL_VERF"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Welding 50 different components fully automatically? That was the challenge for Schroeder Valves, the pump protection fittings manufacturer.

[benefit_subtext] => Welding 50 different components fully automatically? That was the challenge for Schroeder Valves, the pump protection fittings manufacturer. All of the components did have one thing in common, though: they were all rotationally symmetrical...

[teaser] => Welding 50 different components fully automatically? That was the challenge for Schroeder Valves, the pump protection fittings manufacturer. All of the leading specialist’s components did have one thing in common, though: they were all rotationally symmetrical. This was the starting point for welding machine manufacturer EWM in their mission to develop a custom automation solution tailored to this multifaceted challenge – for parts ranging from just a few hundred grams to up to two and a half tonnes.

[casestudy_status] => Schroeder Valves’ pump protection valves are used particularly for transporting critical media: in refineries, in the chemical industry, in processing and in (nuclear) powerplants. Components used in these areas have to be extremely reliable and last for years. Sealing surfaces of components made from cheap construction steel are therefore reinforced with high-quality stainless steel. Due to both the shortage of good welders and growing quality assurance requirements, however, automation of this step was crucial.

[casestudy_solution] => The solution to this challenge soon became clear to EWM automation experts: a robot system was needed. Having to deal with so many different component sizes was a cause for concern. Small parts require higher dynamics than large components. This quickly gave rise to the idea of three processing stations: one large L-positioner with tilting function for the large valve bodies, one small turning/tilting positioner on a system bench for the small valve bodies, and a third station with a system bench without positioners for any other components.

[casestudy_effectiv] => As the parts were rotationally symmetrical, it was easy to teach the components; teaching is always based on the same programs. Users simply have to set the radius, number of passes and the geometric dimensions of the soft armouring and the robot control will take care of the rest. Some components have an interior diameter of just 32 mm, making them extremely difficult to access. This required a special welding torch construction with a particularly small torch head and large torch neck. The fact that EWM produces its own welding torches in-house was a major plus here.

[documents] => {"doc_name":["PraxisReport DE"," CustomerStory EN","Pressemitteilug DE","Press Release EN"],"doc_link":["2021_053-000168-00000_Praxisreport_Heinrich_Schroeder_Valves_DE.pdf","2021_053-000168-00001_Praxisreport_Heinrich_Schroeder_Valves_EN.pdf","DE_EWM_REF_SchroederValves_PM.pdf","EN_EWM_REF_SchroederValves_PM.pdf"],"description":["PraxisReport DE"," CustomerStory EN","Pressemitteilug DE","Press Release EN"]}

[imageslider] => {"image_link":["Bauteile_Bauteilgrößen_web.jpg","Roboteranlage_web.jpg","Schweißbrennerkonstruktion_web.jpg","Teachprozess_Automatisierung_web.jpg","Weichpanzerung_Ventilkoerper-Automatisierung_web.jpg","EWM_EUEN-Schroeder_Valves_web.jpg"],"description":["Abb1_SchroederValves","Abb2_SchroederValves","Abb3_SchroederValves","Abb4_SchroederValves","Abb5_SchroederValves","Abb6_SchroederValves"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 23

[access] => 1

[language] => *

[params] =>

[created] => 2021-12-02 12:13:15

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-01-18 07:28:50

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 5

[hits] => 0

)

[15] => stdClass Object

(

[id] => 23

[catid] => 57

[name] => Heinrich Döpke GmbH

[alias] => heinrich-doepke-gmbh

[customer] => Heinrich Döpke GmbH

[customer_logo] => images/featured/doepke-logo.png

[titelbild] => images/referenzen/EWM_Abb4_Doepke-Rohrschweissen_web.jpg

[sectorId] => COM_EWMREFERENCE_SONSTIGE

[materialId] => ["COM_EWMREFERENCE_SCHWARZ_EDEL"]

[processId] => ["COM_EWMREFERENCE_ALL_VERF"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Every single EWM welding machine saves nearly two tonnes of CO2 compared to the old welding machines...

[benefit_subtext] => Every single EWM welding machine saves nearly two tonnes of CO2 compared to the old welding machines – every year. But for Heinrich Döpke GmbH, replacing their old welding machines was especially attractive because of the government subsidy of 18,000 euros.

[teaser] => Every single EWM welding machine saves nearly two tonnes of CO2 compared to the old welding machines – every year. But for Heinrich Döpke GmbH, replacing their old welding machines was especially attractive because of the government subsidy of 18,000 euros. Under the new EU Ecodesign Directive, the German government subsidises every tonne of CO2 saved with up to 900 euros. According to this directive, all step switch controlled welding machines are to be taken off the market by 2023 because of their high power consumption and be replaced by more energy-efficient inverter welding machines.

[casestudy_status] => The components that are welded by hand every day at Heinrich Döpke GmbH are more than 20 metres long and several metres wide. Plate thicknesses between 5 and 80 mm require a lot of weld seams. Their step switch controlled welding machines were in use constantly. The company was very sceptical about inverter welding machines, as they’d had a lot of bad experiences with them. And because of that, EWM’s field representative received a rather restrained reception when visiting the new potential customer.

[casestudy_solution] => Nevertheless, the Döpke representatives were already impressed with the EWM welding machines’ inverter technology whilst the products were being demonstrated to them on their own components and in their own production hall. In addition to the machines’ technical performance, they were impressed with the warranty period of up to five years without any limit on operating hours. Then, when a large project was pending and several welding machines failed at the same time, they had to make a decision: repair or invest. Ultimately, the BAFA (Federal Office for Economic Affairs and Export Control) subsidy suggested by the EWM field representative, and its approval after only three weeks, were the crucial arguments for converting the entire production to EWM machines.

[casestudy_effectiv] => The German government rewards every tonne of CO2 saved with up to 900 euros. For savings of nearly two tonnes of CO2 per welding machine per year and a total of 13 new Titan XQ 350 puls and Phoenix welding machines, Heinrich Döpke GmbH was awarded a subsidy in the amount of 18,000 euros. Now, the company not only owns energy-saving inverter welding machines, but it can save lots of other costs as well; gas consumption, wear on gas nozzles and working time are also significantly reduced. So, the investment pays off in every regard: for the company and for the environment.

[documents] => {"doc_name":["PraxisReport DE"," CustomerStory EN","Pressemitteilung DE","Press Release EN"],"doc_link":["2021_053-000169-00000_Praxisreport_Heinrich_Döpke_GmbH_DE.pdf","2021_053-000169-00001_Praxisreport_Heinrich_Döpke_GmbH_EN.pdf","2021_DE_REF_Heinrich-Doepke_PM.pdf","2021_EN_REF_Heinrich-Doepke_PM.pdf"],"description":["PraxisReport DE"," CustomerStory EN","Pressemitteilung DE","Press Release EN"]}

[imageslider] => {"image_link":["EWM_Abb1_Schweisser_Doepke_web.jpg","EWM_Abb2_Doepke-Ansprechpartner_Montage_web.jpg","EWM_Abb3_Doepke_Saugbagger_web.jpg","EWM_Abb4_Doepke-Rohrschweissen_web.jpg","EWM_Abb5_Doepke_Beratungssituation_web.jpg","EWM_Abb6_Doepke-Alte-Schweissgeraete_web.jpg"],"description":["Abb1_Doepke","Abb2_Doepke","Abb3_Doepke","Abb4_Doepke","Abb5_Doepke","Abb6_Doepke"]}

[links] => {"doc_name":[""], "doc_link":[""],"description":[""]}

[article_id] => 0

[ordering] => 22

[access] => 1

[language] => *

[params] =>

[created] => 2021-12-02 11:32:28

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-01-18 07:27:16

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 4

[hits] => 0

)

[16] => stdClass Object

(

[id] => 22

[catid] => 57

[name] => SAF-Holland

[alias] => saf-holland

[customer] => SAF-Holland

[customer_logo] => images/featured/SAF-HOLLAND-Group-Logo-3D_grau.png

[titelbild] => images/referenzen/Bild1.jpg

[sectorId] => COM_EWMREFERENCE_FAHRZEUGBAU

[materialId] => ["COM_EWMREFERENCE_STAHL"]

[processId] => ["COM_EWMREFERENCE_MAG_SCHWEISSEN"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Chassis axles designed to carry huge axle loads represent a major challenge in the quality assurance process. This is why SAF-Holland relies on…

[benefit_subtext] => Chassis axles with axle loads of up to 26 tonnes represent a major challenge in the quality assurance process. This is why SAF-Holland relies on ewm Xnet for quality monitoring and control of the manually welded pendulum axes. This welding management system not only continuously monitors and documents every welding parameter, but also ensures the consistent quality of the weld seams.

[teaser] => Chassis axles with axle loads of up to 26 tonnes represent a major challenge in the quality assurance process. This is why SAF-Holland relies on ewm Xnet for quality monitoring and control of the manually welded pendulum axes. This welding management system not only continuously monitors and documents every welding parameter, but also ensures the consistent quality of the weld seams.

[casestudy_status] => SAF-Holland has fully adopted the zero-defect strategy. When it comes to welding processes, this strategy ensures that every weld seam is created using exactly the right welding parameters – every single time. This is easy to verify when using automated and robotic processes, as these parameters are subject to continuous automatic monitoring. It’s more difficult with manual welding. This is where the welding management system ewm Xnet comes in.

[casestudy_solution] => ewm Xnet works continuously to record and store every welding parameter during the manual welding process, allowing them to be accessed and checked whenever necessary. If the welding parameters are within certain predefined tolerances, then the welding result is of the required quality.

In order to achieve a clear allocation between the welding parameters and the component, every single component at SAF-Holland receives a unique dot-peened serial number as well as a QR code. This ensures that the component is clearly defined and allows all parameters to be assigned to it.

[casestudy_effectiv] => This makes the welder’s job a lot easier, and choosing incorrect welding parameters is impossible. Before welding, the welder scans the component’s serial number. They then hold the Xbutton in front of the welding machine. The Xbutton is an RFID chip in which the welding coordination personnel preset the relevant parameters and tolerances. Wrong choices of settings are avoided thanks to the welding parameters being allocated to components on the Xbutton. This is because the welder only has access to the preset parameters. An essential component of the zero-defect strategy.

[documents] => {"doc_name":["PraxisReport DE","CustomerStory EN"],"doc_link":["Praxisreport_SAF_Holland_08-2021_V6.pdf","CustomerStory_SAF_Holland_ewm Xnet_07-2021_EN.pdf"],"description":["PraxisReport DE","CustomerStory DE"]}

[imageslider] => {"image_link":["Bild1.jpg","Bild2.jpg","Bild3.jpg","Bild4.jpg","Bild5.jpg"],"description":["SAF Bild 1","SAF Bild 2","SAF Bild 3","SAF Bild 4","SAF Bild 5"]}

[links] => {"doc_name":["YouTube"],"doc_link":["https://www.youtube.com/watch?v=SOQuZUyadQI"],"description":["SAF Holland nutzt Xnet"]}

[article_id] => 0

[ordering] => 21

[access] => 1

[language] => *

[params] =>

[created] => 2021-07-22 12:49:23

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-01-18 07:36:59

[modified_by] => 590

[metakey] =>

[metadesc] =>

[metadata] => {"robots":"","rights":"","hits":null}

[xreference] =>

[publish_up] => 0000-00-00 00:00:00

[publish_down] => 0000-00-00 00:00:00

[images] =>

[description] =>

[version] => 10

[hits] => 0

)

[17] => stdClass Object

(

[id] => 21

[catid] => 57

[name] => Geschwister Scholl school Leutkirch

[alias] => geschwister-scholl-schule-leutkirch

[customer] => Geschwister-Scholl-Schule Leutkirch

[customer_logo] => images/featured/gss-logo-hoch-eda04ffd.png

[titelbild] => images/referenzen/Abb1_Unterricht-KFZ_web.jpg

[sectorId] => COM_EWMREFERENCE_SONSTIGE

[materialId] => ["COM_EWMREFERENCE_ALL"]

[processId] => ["COM_EWMREFERENCE_ALL_VERF"]

[published] => 1

[checked_out] => 0

[checked_out_time] => 0000-00-00 00:00:00

[benefit_headline] => Geschwister Scholl school uses EWM complete solution.

Vocational students are being trained with ewm Xnet

[benefit_subtext] => The Geschwister Scholl school, a competence centre for business, care, social services and technology in Leutkirch, is preparing its students for a future in Industry 4.0. To that end, Anton Netzer, technology instructor in the metal construction department, uses the Welding 4.0 solution by EWM AG in Mündersbach.

[teaser] => Industry 4.0 is when people, machines and industrial processes connect intelligently. This is how the German Federal Ministry for Economic Affairs and Energy defines the fourth industrial revolution that is currently taking place in companies. The Geschwister Scholl school, a competence centre for business, care, social services and technology in Leutkirch, is preparing its students for this aspect of the future. To that end, Anton Netzer, technology instructor in the metal construction department, uses the Welding 4.0 solution by EWM AG in Mündersbach.

[casestudy_status] => Industry 4.0 is currently a hot topic for all businesses within the world of metal construction. Many companies are already working with networked processes and using state-of-the-art welding machines and digital management solutions. The Geschwister Scholl school was faced with the challenge of preparing its students for this new reality and training them accordingly. “We want our students to learn the technologies that are offered in companies,” says Netzer. However, until 2020, the school only had access to step switch-controlled machines.

[casestudy_solution] => The school’s technical arsenal of nine welding booths was upgraded with Welding 4.0, the EWM complete system for welding. It includes state-of-the-art welding machines and the digital quality management system for welding, ewm Xnet. The future construction mechanics and construction technicians training here now work with the EWM inverter welding machine Tetrix 230 for TIG and the Titan XQ puls for MIG/MAG and MMA. In addition, the multi-process welding machine provides the trainees directly with all the innovative XQ welding processes by EWM.

[casestudy_effectiv] => The modern EWM complete solution has completely changed training at the vocational school. Students now learn on the same machines that they use at their training companies. What’s more, the system with ewm Xnet also detects parameter changes immediately and signals these to the user. Anton Netzer takes advantage of these features for his training: “We can weld and then immediately look at the data together, analyse it and complete it. Where are the mistakes? Where is room for improvement?” explains Netzer.

[documents] => {"doc_name":["PraxisReport Geschw. Scholl Schule DE"," CustomerStory Geschw. Scholl Schule EN"],"doc_link":["PraxisReport_Geschwister-Scholl-Schule_ewm-Xnet_2020.pdf","PraxisReport_Geschwister-Scholl-Schule_ewm-Xnet_2020_EN.pdf"],"description":["PraxisReport Geschw. Scholl Schule DE"," CustomerStory Geschw. Scholl Schule EN"]}

[imageslider] => {"image_link":["Abb1_Unterricht-KFZ_web.jpg","Abb2_Schweisskabinen_web.jpg","Abb3_ewmXnet_web.jpg","Abb4_Kabine3_web.jpg","Abb5_Unterricht_web.jpg","Abb6_Netzer_Golz_web.jpg"],"description":["Abb 1","Abb 2","Abb 3","Abb 4","Abb 5","Abb 6"]}

[links] => {"doc_name":["Video"],"doc_link":["https://www.youtube.com/watch?v=9_S0RiJFL_U"],"description":["Geschwister-Scholl-Schule Leutkirch nutzt ewm-Xnet"]}

[article_id] => 0

[ordering] => 20

[access] => 1

[language] => *

[params] =>

[created] => 2021-01-25 11:07:50

[created_by] => 590

[created_by_alias] =>

[modified] => 2022-01-18 07:30:49

[modified_by] => 590

[metakey] =>