- U bevindt zich hier:

- Start

PraxisReport

| Branche: | Nuclear and magnetic-technology |

| Materiaal: | |

| Lasprocessen: | forceTig |

| Trefwoorden: | TIG, Automatisierung , automatisiertschweissen, |

When radioactive materials need to be safely enclosed in containers, every detail counts

De uitgangspositie:

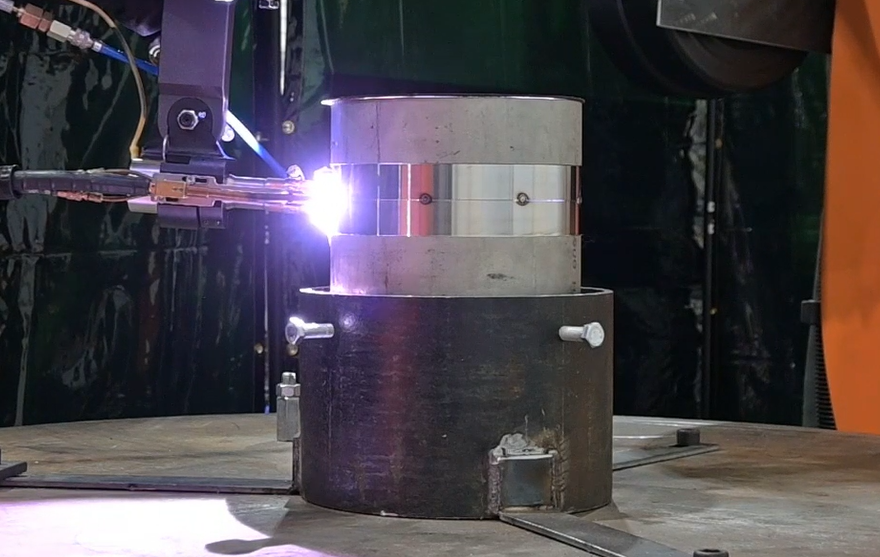

Lifelong and absolutely secure sealing is a top priority when it comes to transporting and storing highly radioactive material in specially manufactured stainless steel containers. No one is allowed to be near the welding process when the containers with the nuclear material inside are being sealed. The protection of personnel and absolute process reliability are paramount, so reliable and automated welding solutions are essential. In collaboration with TANICS™, the joint venture between Amentum and Langfields Ltd., we have therefore developed TANICS™ R-TIG.

Lifelong and absolutely secure sealing is a top priority when it comes to transporting and storing highly radioactive material in specially manufactured stainless steel containers. No one is allowed to be near the welding process when the containers with the nuclear material inside are being sealed. The protection of personnel and absolute process reliability are paramount, so reliable and automated welding solutions are essential. In collaboration with TANICS™, the joint venture between Amentum and Langfields Ltd., we have therefore developed TANICS™ R-TIG.

De oplossing:

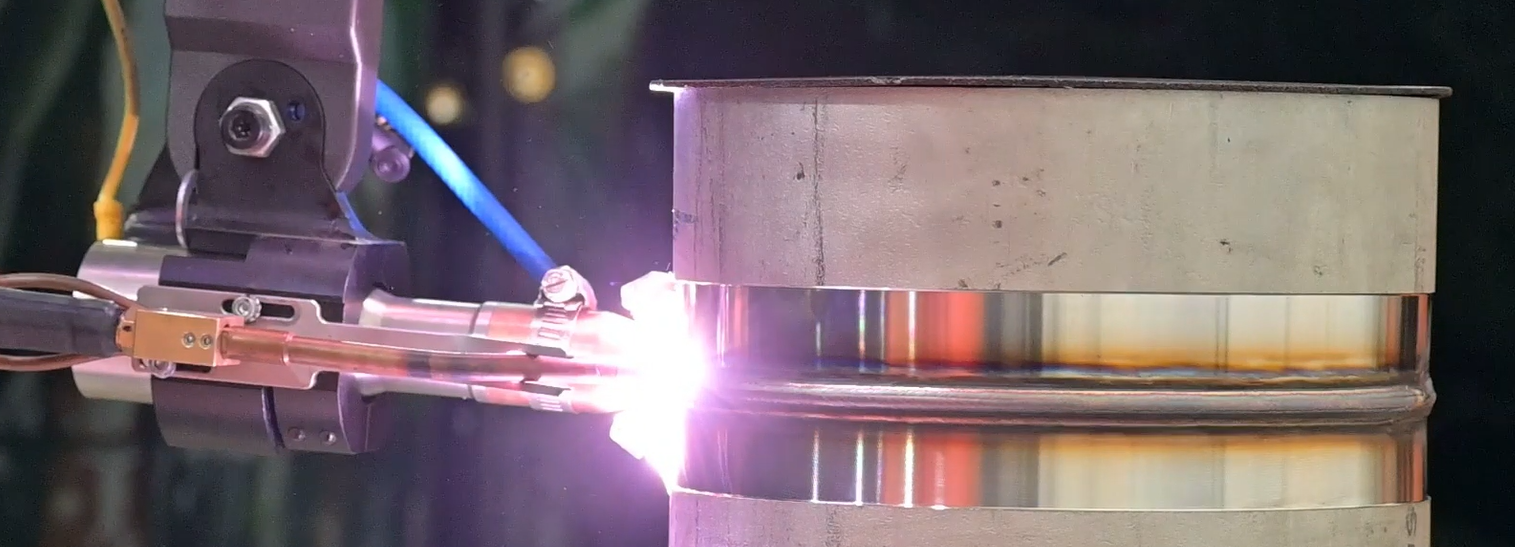

TANICS™ R-TIG is a robot-assisted welding system that, in combination with EWM's high-performance forceTig® TIG welding process, meets the highest standards of quality, safety and flexibility in accordance with PD5500 Category 1 and Sellafield Build Level specifications. Different container sizes and seam geometries can be reliably welded – directly on site, fully automated and remote-controlled. Cameras mounted directly on the robot and an integrated inspection system enable the weld seam to be viewed from different angles and ensure seamless quality control.

TANICS™ R-TIG is a robot-assisted welding system that, in combination with EWM's high-performance forceTig® TIG welding process, meets the highest standards of quality, safety and flexibility in accordance with PD5500 Category 1 and Sellafield Build Level specifications. Different container sizes and seam geometries can be reliably welded – directly on site, fully automated and remote-controlled. Cameras mounted directly on the robot and an integrated inspection system enable the weld seam to be viewed from different angles and ensure seamless quality control.

Het succes:

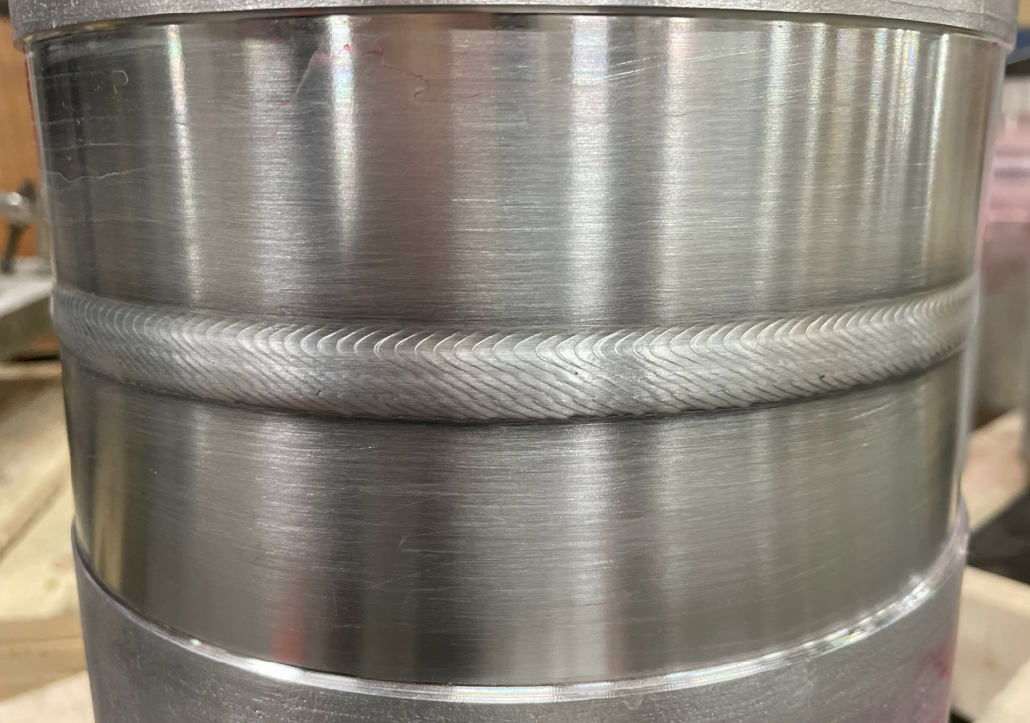

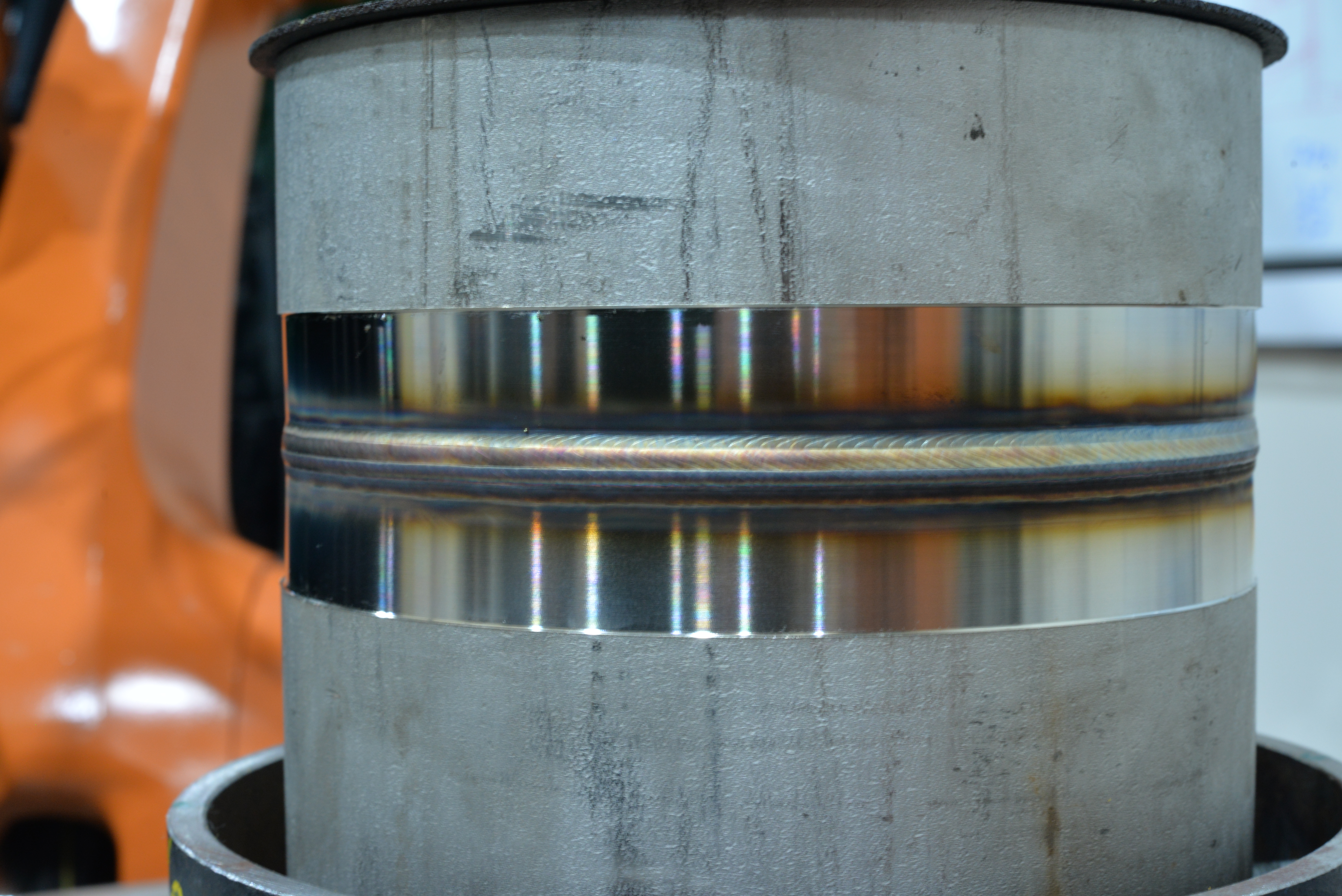

Reproducibility of seam quality, process reliability and personnel protection. The specifications at the start of the collaboration were clear. And it is precisely at the point where conventional TIG welding reaches its limits that the newly developed TANICS™ R-TIG solution comes into play. It is a practical response to the challenges faced by the nuclear industry and other sectors, meets the strict standards of European norms and is ASME-qualified. TANICS™ R-TIG provides optimum protection for personnel in hazardous environments and ensures the highest weld seam quality at all times.

Reproducibility of seam quality, process reliability and personnel protection. The specifications at the start of the collaboration were clear. And it is precisely at the point where conventional TIG welding reaches its limits that the newly developed TANICS™ R-TIG solution comes into play. It is a practical response to the challenges faced by the nuclear industry and other sectors, meets the strict standards of European norms and is ASME-qualified. TANICS™ R-TIG provides optimum protection for personnel in hazardous environments and ensures the highest weld seam quality at all times.