- Jesteś tutaj:

- Start

CustomerStory

| Industry: | Other |

| Material: | Metal Steel |

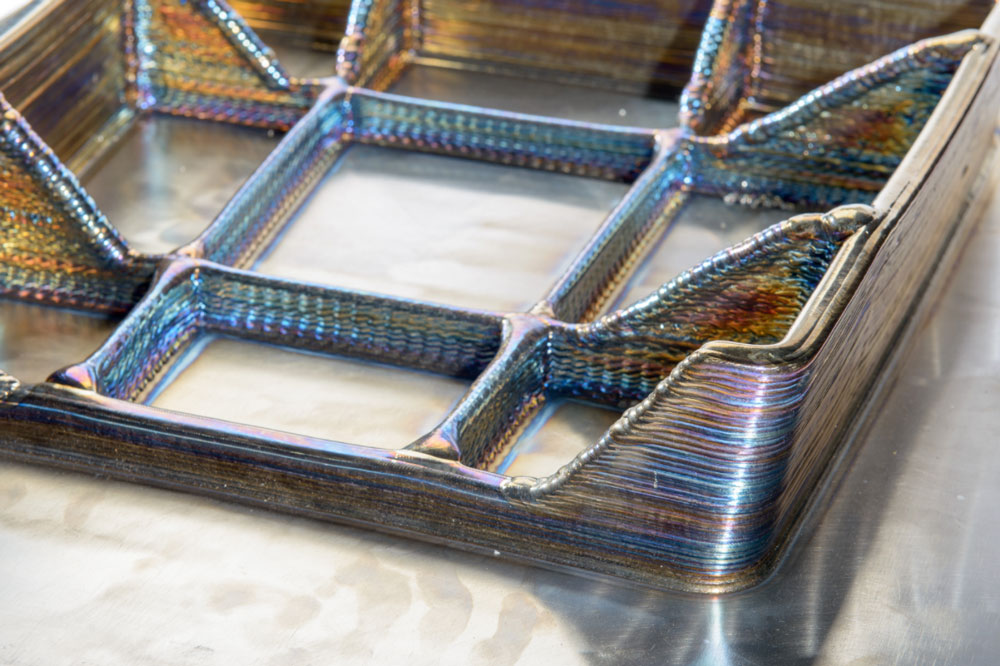

| Welding processes: | WAAM (additive manufacturing) |

| Keywords: | WAAM, 3D-Druck, Schichtbildung, Tetrix352, Tetrix552, |

Precise welding technology for additive manufacturing

Wire additive manufacturing (WAAM) offers enormous opportunities, but also presents companies with special challenges. In order to reliably build complex metal structures, the welding systems used must operate with absolute precision and stability over many hours. For WAAM3D, it was therefore clear that a solution had to be found that would ensure uniform layer formation, high repeatability and consistent quality, even during long manufacturing processes.

The choice fell on plasma welding systems from EWM. With the Tetrix 352 and 552 models, WAAM3D can precisely control the process parameters and thus ensure controlled, reproducible material application. The high duty cycle and flexibility in the use of different materials make the devices the ideal solution for the special requirements of WAAM technology. In addition, the power sources can be easily integrated into WAAM3D's existing automation systems, enabling a consistently efficient and robust production process.

By using EWM welding technology, WAAM3D has been able to significantly increase process reliability and stability. Welding errors, especially with demanding materials such as titanium or Inconel, are reliably avoided. The company benefits from consistently high component quality and can guarantee its customers reliable and reproducible results. In addition to the technical advantages, WAAM3D also values its close cooperation with EWM: fast support, expert advice and the certainty of being well equipped for the future development of the technology.