I

I  I

I  I

I

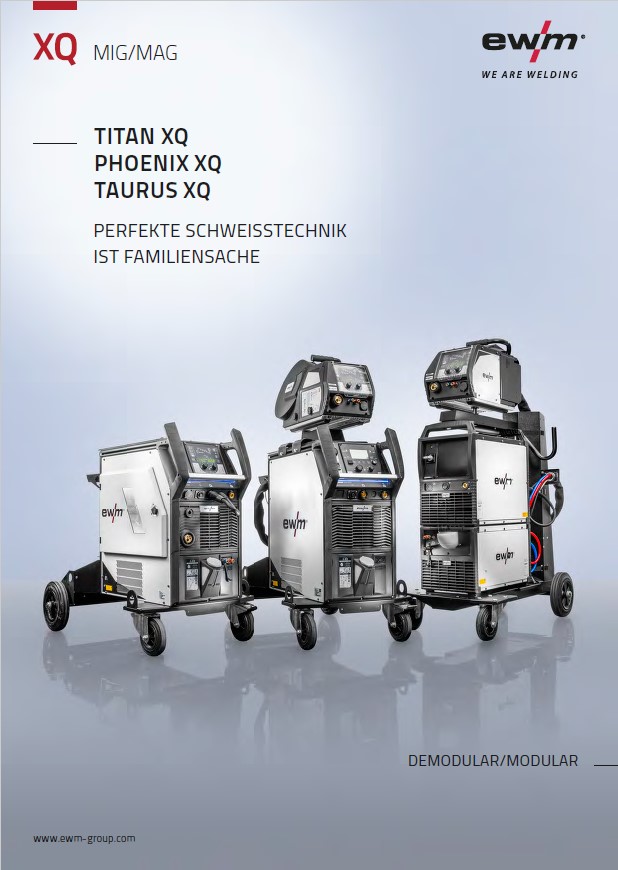

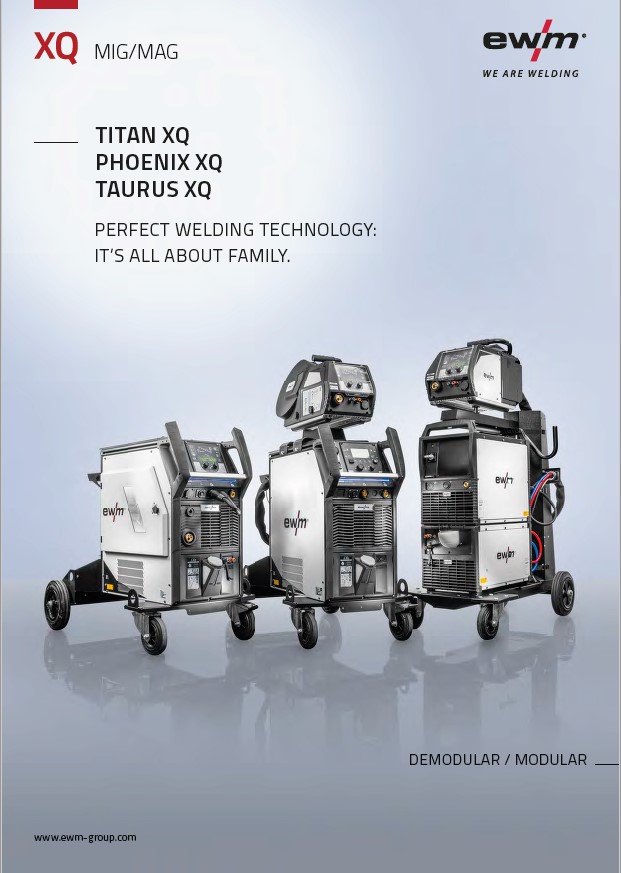

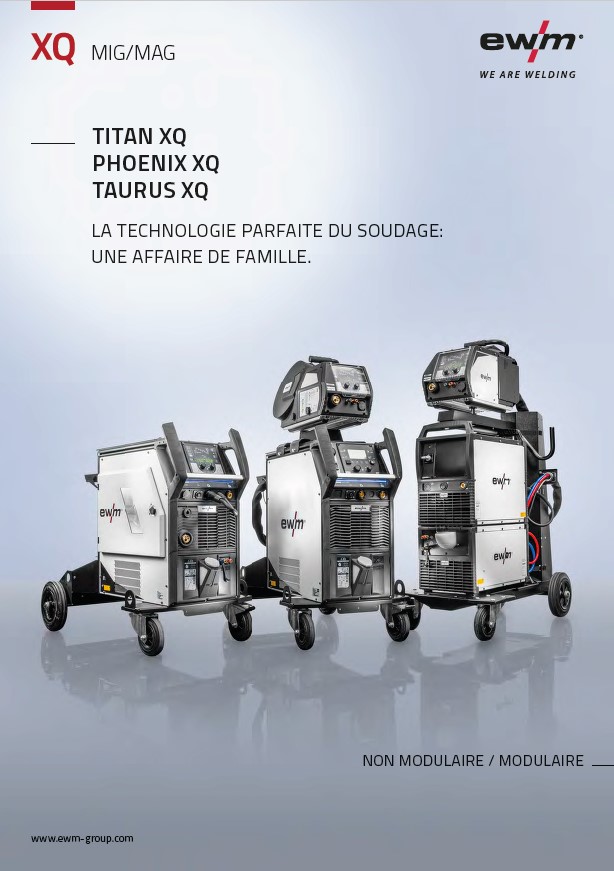

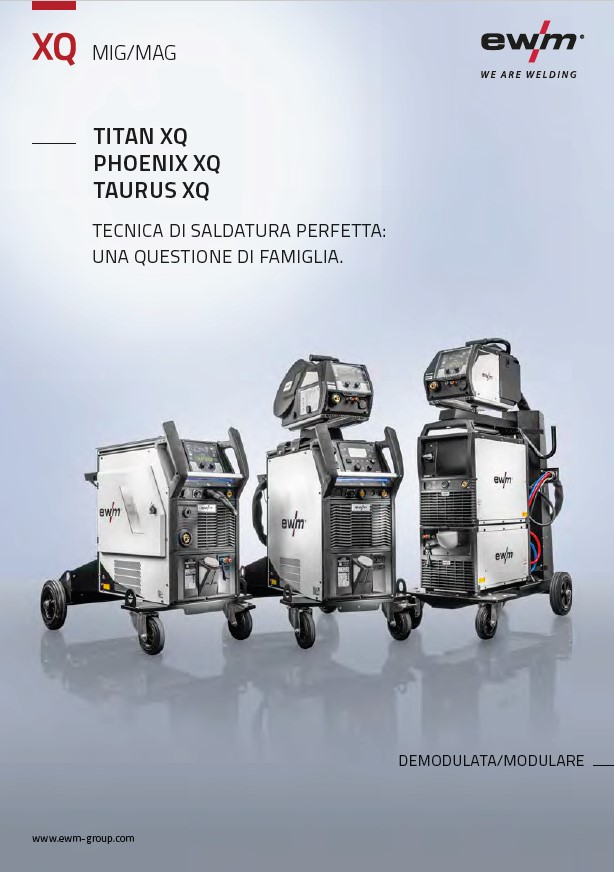

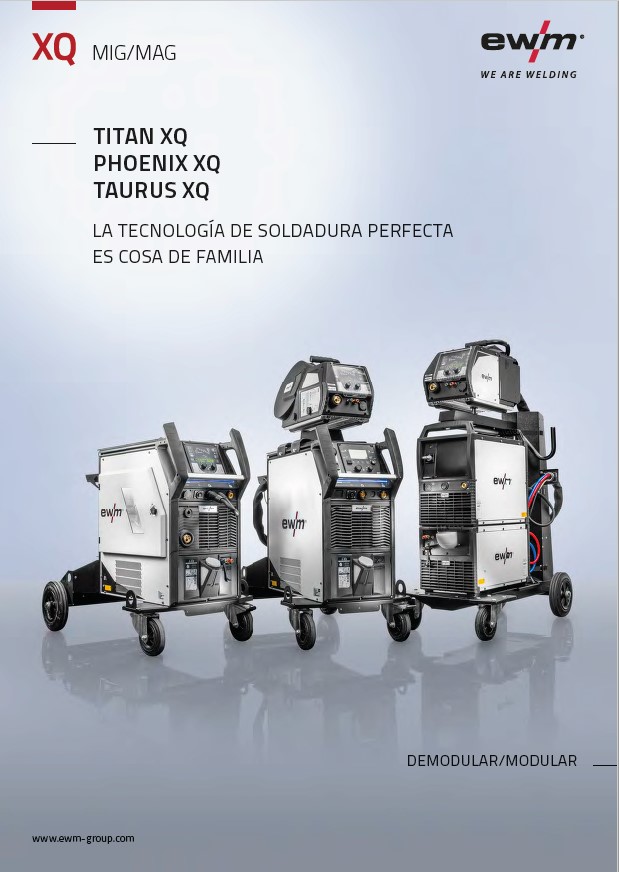

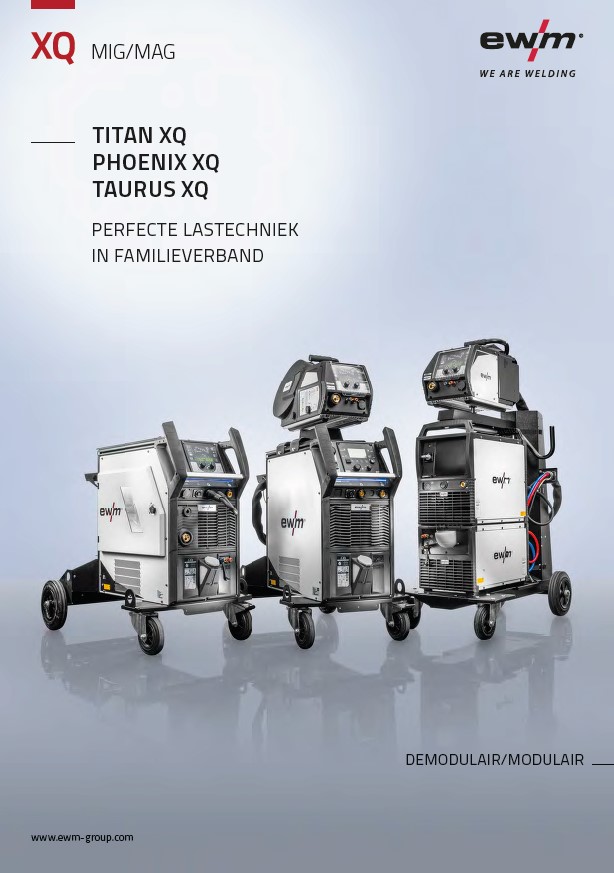

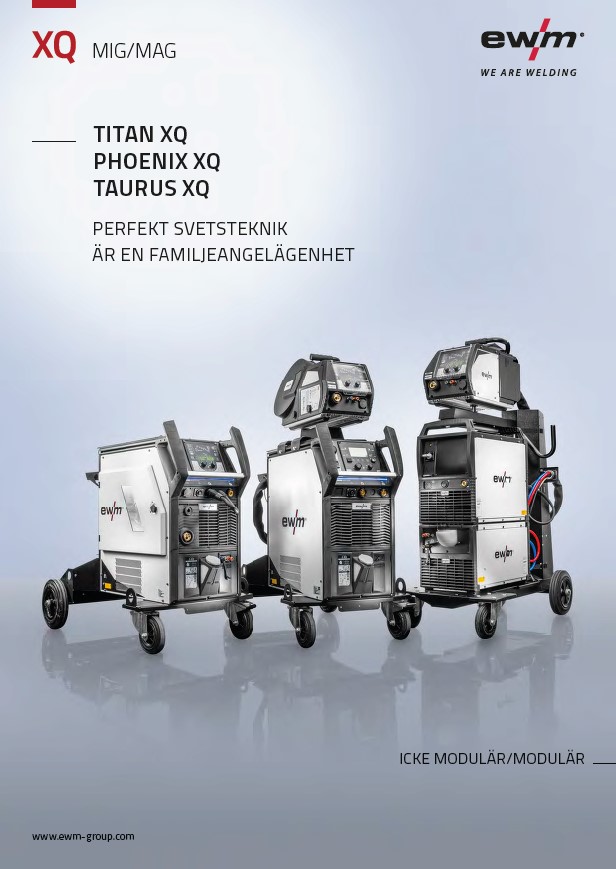

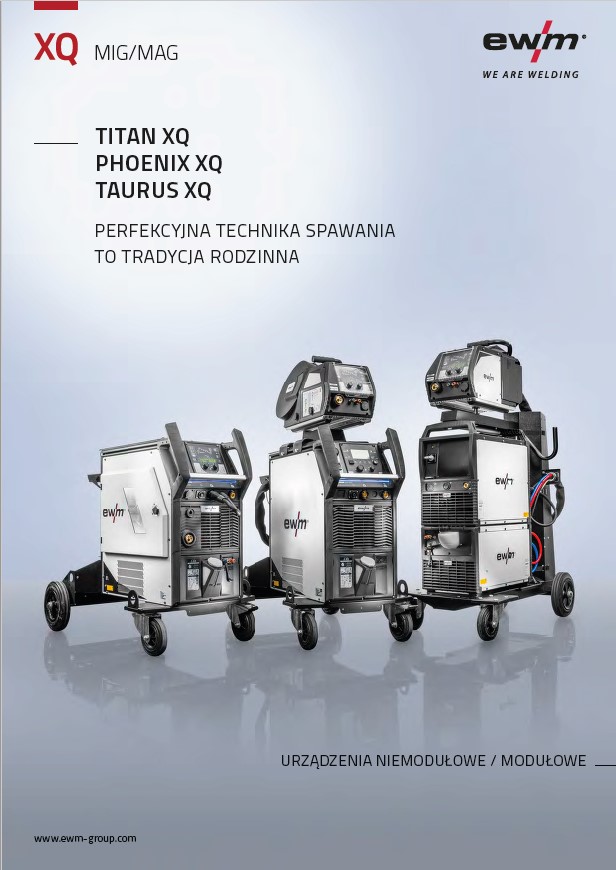

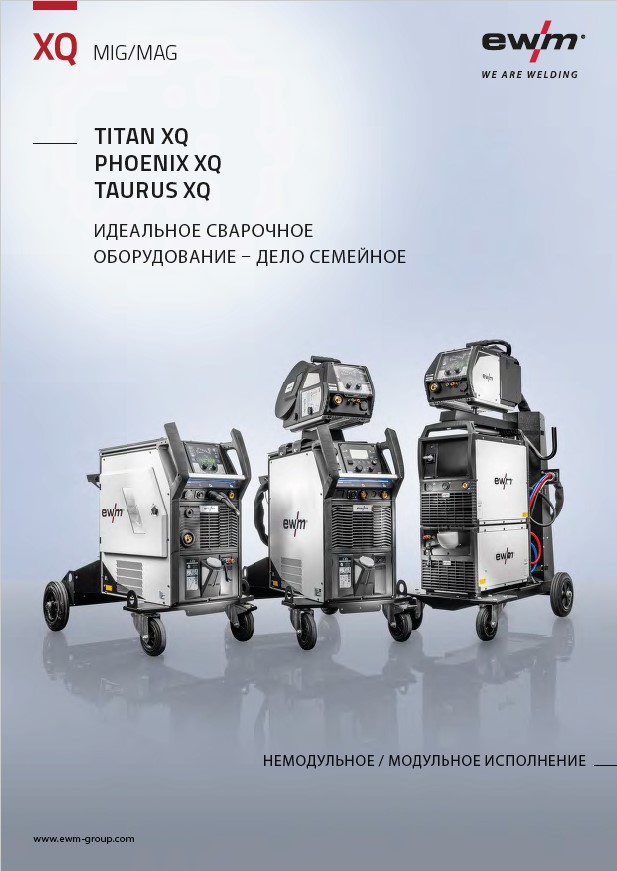

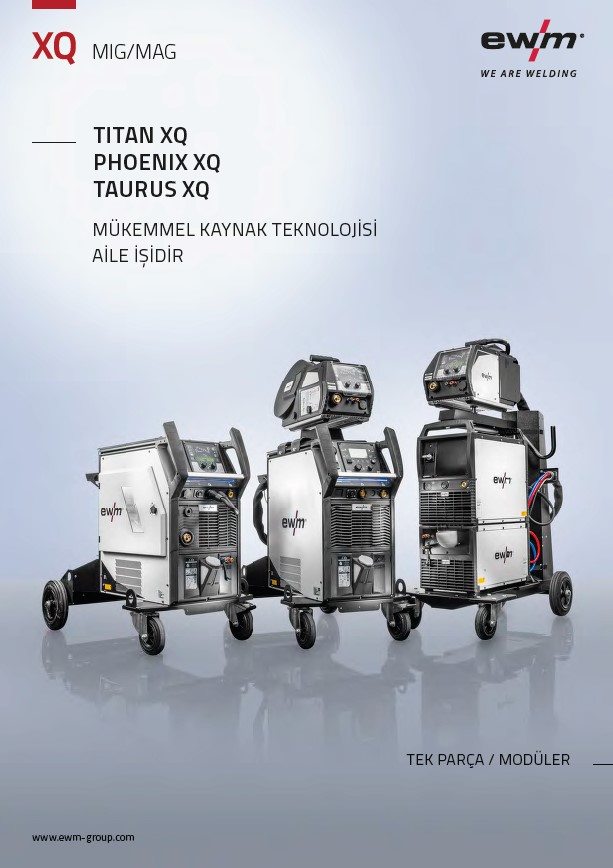

THE MIG/MAG FAMILY – DEMODULAR/MODULAR

Every welding task is different – and so is every welder. That’s why we don’t just offer one MIG/MAG multi-process welding machine, we offer a whole family! And one thing is consistent throughout the family: each machine allows you to weld comfortably and economically while achieving optimal results – whether it’s a demodular machine like the Titan XQ puls, Phoenix XQ puls or Taurus XQ Synergic; or modular such as Phoenix XQ puls, Taurus XQ Synergic or Taurus XQ Basic.

Demodular

Whether you’re working with a decompact system with separate wire feeder on large components or in hard-to-reach areas or with the compact variants in the welding booth: the XQ range (both gas- and water-cooled) offers you a custom solution for all your needs. The machines boast an above-average duty cycle* to make your work more effective and, thanks to the wide range of accessories, there’s always a machine to meet any special, unusual requirements. What’s more, each machine can be individually configured.

Modular

Modular casing system for workstations in all kinds of environments. Gas- or water-cooled. Flexible design: suitable for use both in production or as a mobile machine on the construction site or job. Portable or on a trolley Space-saving and lightweight design guarantees flexibility and mobility.

-

-

Technical data – Titan XQ 350 puls

适用 Titan XQ 350 puls DW R1 5m 焊接电流设置范围 5 A - 350 A 暂载率 40 °C 350 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 19.3 kVA 效率 88 % 功率消耗 Pi 26 W 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Technical data – Titan XQ 400 puls

适用 Titan XQ 400 puls DW R1 5m 焊接电流设置范围 5 A - 400 A 暂载率 40 °C 400 A / 80 % 370 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 23.8 kVA 效率 88 % 功率消耗 Pi 26 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Technical data – Titan XQ 500 puls

适用 Titan XQ 500 puls DW R1 5m 焊接电流设置范围 5 A - 500 A 暂载率 40 °C 500 A / 80 % 470 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 34 kVA 效率 88 % 功率消耗 Pi 28 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Technical data – Titan XQ 600 puls

适用 Titan XQ 600 puls DW R1 5m 焊接电流设置范围 5 A - 600 A 暂载率 40 °C 600 A / 40 % 550 A / 60 % 470 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 46 kVA 效率 88 % 功率消耗 Pi 28 W 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A

-

Technical data – Titan XQ 350 puls C

适用 Titan XQ 350 puls CW HP R1 5m 焊接电流设置范围 5 A - 350 A 暂载率 40 °C 350 A / 80 % 320 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 19.3 kVA 效率 88 % 功率消耗 Pi 34 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1,0-1,2 mm UNI / 钢 丝盘直径 D200 / D300 焊枪接口 Eurozentralanschluss 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 131 kg / 288.9 lbs 标准 IEC 60974-1, -2, -5, -10 CL.A Technical data – Titan XQ 400 puls C

适用 Titan XQ 400 puls CW HP R1 5m 焊接电流设置范围 5 A - 400 A 暂载率 40 °C 400 A / 60 % 350 A / 80 % 320 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 23.8 kVA 效率 88 % 功率消耗 Pi 34 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1,0-1,2 mm UNI / 钢 丝盘直径 D200 / D300 焊枪接口 Eurozentralanschluss 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 131 kg / 288.9 lbs 标准 IEC 60974-1, -2, -5, -10 CL.A

-

Titan XQ puls welding processes

- Welding process finder

rootArc® XQ/rootArc® puls XQ

rootArc® XQ/rootArc® puls XQ coldArc® XQ/coldArc® puls XQ

coldArc® XQ/coldArc® puls XQ forceArc® XQ/forceArc® puls XQ

forceArc® XQ/forceArc® puls XQ wiredArc XQ/wiredArc puls XQ

wiredArc XQ/wiredArc puls XQ acArc puls XQ

acArc puls XQ Positionweld XQ

Positionweld XQ superPuls

superPuls Puls

Puls Standard (MIG/MAG)

Standard (MIG/MAG)- TIG and MMA welding, gouging

-

-

-

Technical data – Phoenix XQ 350 puls

适用 Phoenix XQ 350 puls DW R1 5m 焊接电流设置范围 5 A - 350 A 暂载率 40 °C 350 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 19.3 kVA 效率 88 % 功率消耗 Pi 26 W 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Technical data – Phoenix XQ 400 puls

适用 Phoenix XQ 400 puls DW R1 5m 焊接电流设置范围 5 A - 400 A 暂载率 40 °C 400 A / 80 % 370 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 23.8 kVA 效率 88 % 功率消耗 Pi 26 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Technical data – Phoenix XQ 500 puls

适用 Phoenix XQ 500 puls DW R1 5m 焊接电流设置范围 5 A - 500 A 暂载率 40 °C 500 A / 80 % 470 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 34 kVA 效率 88 % 功率消耗 Pi 28 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Technical data – Phoenix XQ 600 puls

适用 Phoenix XQ 600 puls DW R1 5m 焊接电流设置范围 5 A - 600 A 暂载率 40 °C 600 A / 40 % 550 A / 60 % 470 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 46 kVA 效率 88 % 功率消耗 Pi 28 W 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A

-

Technical data – Phoenix XQ 350 puls C

适用 Titan XQ 350 puls CW HP R1 5m 焊接电流设置范围 5 A - 350 A 暂载率 40 °C 350 A / 80 % 320 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 19.3 kVA 效率 88 % 功率消耗 Pi 34 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1,0-1,2 mm UNI / 钢 丝盘直径 D200 / D300 焊枪接口 Eurozentralanschluss 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 131 kg / 288.9 lbs 标准 IEC 60974-1, -2, -5, -10 CL.A Technical data – Phoenix XQ 400 puls C

适用 Titan XQ 400 puls CW HP R1 5m 焊接电流设置范围 5 A - 400 A 暂载率 40 °C 400 A / 60 % 350 A / 80 % 320 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 23.8 kVA 效率 88 % 功率消耗 Pi 34 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1,0-1,2 mm UNI / 钢 丝盘直径 D200 / D300 焊枪接口 Eurozentralanschluss 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 131 kg / 288.9 lbs 标准 IEC 60974-1, -2, -5, -10 CL.A

-

Phoenix XQ puls welding processes

- Welding process finder

rootArc® XQ/rootArc® puls XQ

rootArc® XQ/rootArc® puls XQ forceArc® XQ/forceArc® puls XQ

forceArc® XQ/forceArc® puls XQ Positionweld XQ for aluminium

Positionweld XQ for aluminium superPuls

superPuls Puls

Puls Standard (MIG/MAG)

Standard (MIG/MAG)- TIG and MMA welding, gouging

-

-

-

Technical data – Taurus XQ 350 Synergic

适用 Taurus XQ 350 Synergic DW R1 5m 焊接电流设置范围 5 A - 350 A 暂载率 40 °C 350 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 19.3 kVA 效率 88 % 功率消耗 Pi 26 W 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Technical data – Taurus XQ 400 Synergic

适用 Taurus XQ 400 Synergic DW R1 5m 焊接电流设置范围 5 A - 400 A 暂载率 40 °C 400 A / 80 % 370 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 23.8 kVA 效率 88 % 功率消耗 Pi 26 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Technical data – Taurus XQ 500 Synergic

适用 Taurus XQ 500 Synergic DW R1 5m 焊接电流设置范围 5 A - 500 A 暂载率 40 °C 500 A / 80 % 470 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 34 kVA 效率 88 % 功率消耗 Pi 28 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Technical data – Taurus XQ 600 Synergic

适用 Taurus XQ 600 Synergic DW R1 5m 焊接电流设置范围 5 A - 600 A 暂载率 40 °C 600 A / 40 % 550 A / 60 % 470 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 46 kVA 效率 88 % 功率消耗 Pi 28 W 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 128.5 kg / 283.3 lbs 标准 IEC 60974-1, -2, -10 CL.A

-

Technical data – Taurus XQ 350 Synergic C

适用 Titan XQ 350 puls CW HP R1 5m 焊接电流设置范围 5 A - 350 A 暂载率 40 °C 350 A / 80 % 320 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 19.3 kVA 效率 88 % 功率消耗 Pi 34 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1,0-1,2 mm UNI / 钢 丝盘直径 D200 / D300 焊枪接口 Eurozentralanschluss 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 131 kg / 288.9 lbs 标准 IEC 60974-1, -2, -5, -10 CL.A Technical data – Taurus XQ 400 Synergic C

适用 Titan XQ 400 puls CW HP R1 5m 焊接电流设置范围 5 A - 400 A 暂载率 40 °C 400 A / 60 % 350 A / 80 % 320 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 460 V 3 x 480 V - 500 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 23.8 kVA 效率 88 % 功率消耗 Pi 34 W 送丝速度 0.5 m/min - 25 m/min 19.685 ipm - 984.253 ipm 1,0-1,2 mm UNI / 钢 丝盘直径 D200 / D300 焊枪接口 Eurozentralanschluss 1500 W 3.5 bar 水箱容量 8 l 防护等级 IP23 EMC 等级 A 1152 mm x 686 mm x 976 mm 45.4 inch x 27 inch x 38.4 inch 重量 131 kg / 288.9 lbs 标准 IEC 60974-1, -2, -5, -10 CL.A

-

Taurus XQ Synergic welding processes

![XQ welding process]()

- Welding process finder

rootArc® XQ

rootArc® XQ forceArc® XQ

forceArc® XQ superPuls

superPuls Puls

Puls Standard (MIG/MAG)

Standard (MIG/MAG)- TIG and MMA welding, gouging

-

-

An overview of the EWM XQ series

- / rootArc® XQ / rootArc® puls XQ

- / coldArc® XQ / coldArc® puls XQ

- / forceArc® XQ / forceArc® puls XQ

- / wiredArc XQ / wiredArc puls XQ

- / Standard (MIG/MAG)

- / Pulse

- / Positionweld

- / superPuls

- / TIG

- / MMA

- / Gouging

- / rootArc® XQ / rootArc® puls XQ

- / forceArc® XQ / forceArc® puls XQ

- / Standard (MIG/MAG)

- / Pulse

- / Positionweld for aluminium

- / superPuls

- / TIG

- / MMA

- / Gouging

- / rootArc® XQ

- / forceArc® XQ

- / Standard (MIG/MAG)

- / superPuls

- / TIG

- / MMA

- / Gouging

The XQ welding processes:

rootArc XQ/rootArc puls XQ – Perfect root welding, easy-to-execute filler and final passes

coldArc XQ/coldArc puls XQ – Heat-minimised arc for thin metal sheet welding

forceArc XQ/forceArc puls XQ – Powerful high-performance arc with deep penetration

wiredArc XQ/wiredArc puls XQ – Powerful high-performance arc with penetration independent of stick-out thanks to dynamic wire control (penetration stabilisation)

Standard – Perfect short and spray arcs

Pulse – Low-spatter pulsed arc

Positionweld – Simple positional welding without the “Christmas tree” technique

superPuls – Heat-reduced interval welding between two operating points (high-current and low-current phases freely adjustable)

XQ series – individually configurable welding machine

XQ – a series of perfection. Individually configurable casing design for more flexibility thanks to a wide range of options.

Drive XQ wire feeders – great options to make life easier

-

Drive XQ wire feeder

At just 13 kg (excl. wire spool) and with a balanced, ergonomic handle, the Drive XQ wire feeder is the perfect companion for impassable scaffolding, hard-to-reach work spaces or large components – it can even fit through manholes.

-

MIG/MAG wire feeder for XQ welding machines

- Suitable for 200-mm or 300-mm wire spools

- Easy to transport thanks to its low weight and compact design

- Interior lighting

- Stable base construction (continuous cast aluminium) with sliding rails as standard

- Transparent protective cap – welding parameters visible at all times

- Robust electronics protected in a dust-free area

- Protected arrangement of connections for intermediate hose packages and control cables

- Non-specialist staff can change hose packages without tools

- eFeed: innovative 4-roll drive (quadruple meshing)

- Equipped with 1.0–1.2-mm UNI rolls for low to high-alloy steel

![Drive XQ IC 200 wire feeder]()

-

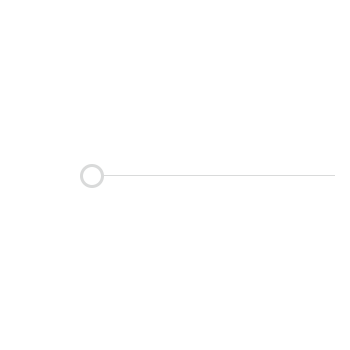

DGC – electronic gas flow control: Save gas with ease and accuracy (optional)

- Prevents welding errors caused by too much or too little gas

- Efficiency through gas savings thanks to accurate settings

- Fully reproducible thanks to digital configuration and saving to the respective JOB (welding task)

- Constant gas flow rate thanks to electronic adjustment

- Digital display of nominal and actual gas flow rate values in l/min

- Extremely advantageous with long hose packages, e.g. for shipbuilding and steel construction

- No gas blast with turbulence when igniting the arc as the electrical valve opens and closes gently

![DGC graphics]()

-

WRS – wire reserve sensor: no unexpected occurrences during welding

- The sensor warns at 10% residual quantity of the wire spool by means of a control lamp.

- It reduces the risk of seam errors occurring due to the wire running out during welding.

- A spool change can be planned in advance, which reduces downtime.

![XQ series Drive 4]()

-

WHS – wire spool heater: regulated heat for better seam quality (optional)

- The wire is pre-heated, which reduces the build-up of moisture on the welding wire.

- The temperature is regulated at 50 °C (adjustable).

- The welding results are perfect, especially for aluminium.

![XQ series Drive 4]()

-

Electrode holder connection (optional)

- Ideal for MMA welding

- Ideal for gouging

![XQ series Drive 4]()

-

-

Drive XQ IC 200 wire feeder

Weighing in at just 10 kg, this robust, resilient machine is perfect for work on shipyards and in hard-to-reach places.

-

Drive XQ IC 200 wire feeder

- MIG/MAG wire feeder for XQ welding machines

- Powerful, high-precision EWM eFeed 4-roll wire feeder to reliably feed all solid and flux cored wires

- Easy to transport thanks to its low weight and compact design

- Suitable for 5-kg D200 wire spools

- Lightweight and robust design, ideal for shipyard applications

- Robust electronics protected in a dust-free area

- Optionally with integrated flow meter

![Drive XQ IC 200 wire feeder]()

-

Flow meter (optional)

Optional analogue gas flow rate adjustment with gas flow meter

- Flow meter for setting the shielding gas flow manually

- Precise setting and checking of the gas quantity at the welding site

- Extremely advantageous with long hose packages, e.g. for shipbuilding and steel construction

![Flow meter]()

-

Securely connected

Retrofitting option: Water cooling for wire feeder

- Key switch – control shut-off to protect against operator error

- Tool-free changing of intermediate hose packages

- Easy-to-access, internal hose package connections, fully protected thanks to cover cap

- Strain-relieved hose package thanks to quick connect coupling system

![Cool hose package connections]()

-

Handle/ON TG D12 (optional)

Retrofitting option: Carrying handle and strap

![Handle/ON TG D12]()

-

Transparent cover lens

Transparent cover lens for wire feed controls

- Cover lens made of transparent plastic

- Protects the controls against dirt and damage

- Operation still possible thanks to recesses for the operating knobs

![Cover lens]()

-

PS drive D12 (optional)

Pivot support (360°) for wire feeders

- Wire feeder pivots 360° on the welding machine

- Increased working radius thanks to rotatability

- Wire feeder can be mounted and removed without tools

- When using on welding machines with casing type F.0006, option ON PS F06 1D01 must be present

- For use on Trolly XQ 55-5, option ON PS Trolly XQ 55-5 is required

- For use on Trolly 55-6, cross arm ON PS Trolly 55-5/55-6 is required

![PS drive D12]()

-

Wheel set – facilitates work at frequently changing welding sites (optional)

Wheel assembly kit

- Wheel set – facilitates work at frequently changing welding sites

![Wheel assembly kit]()

-

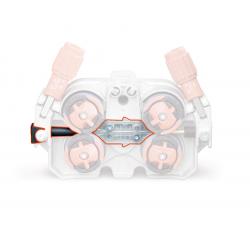

eFeed wire feeder – full traction

-

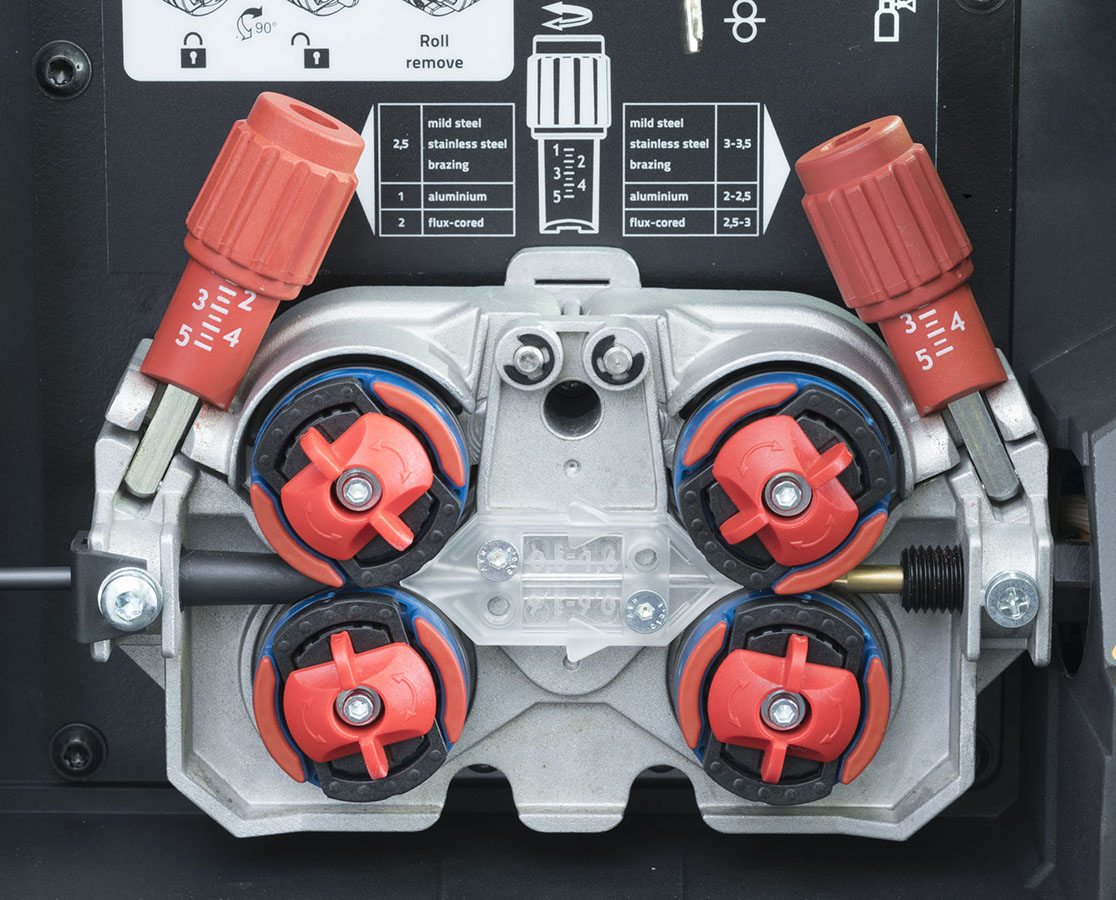

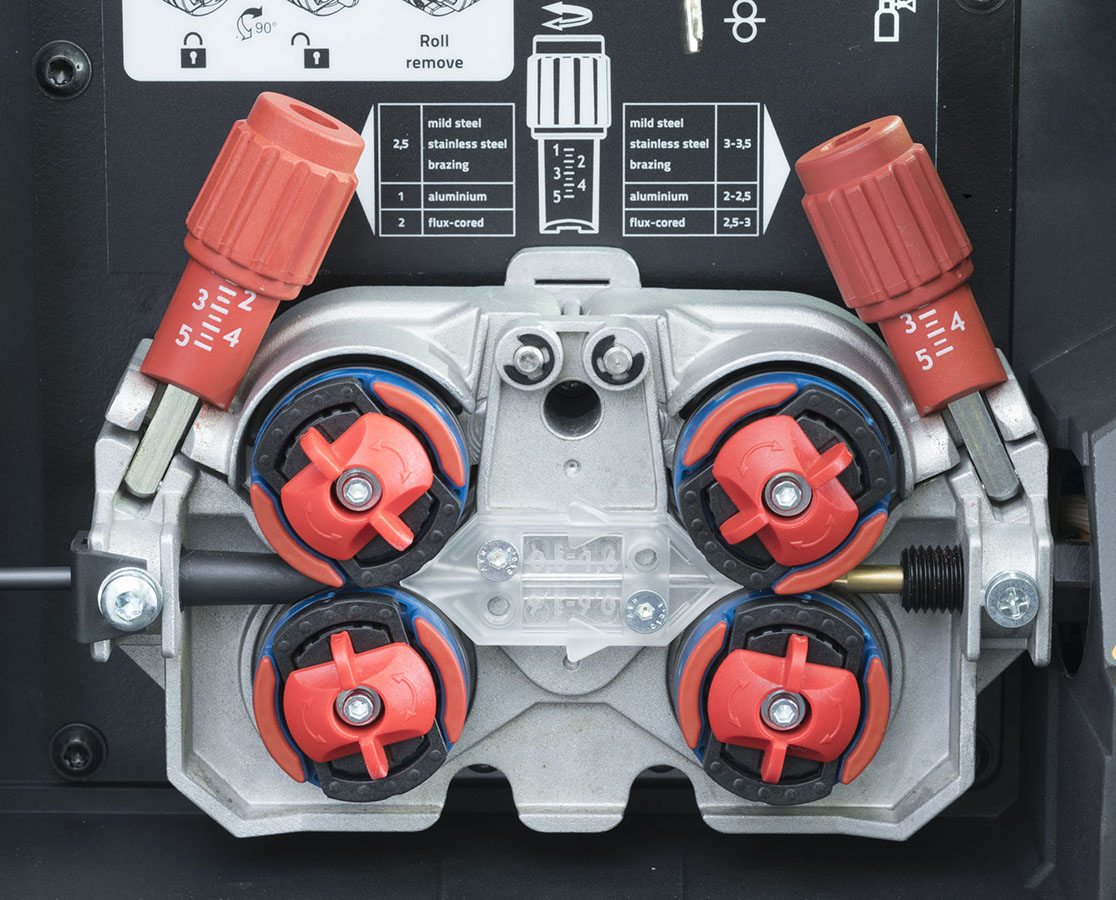

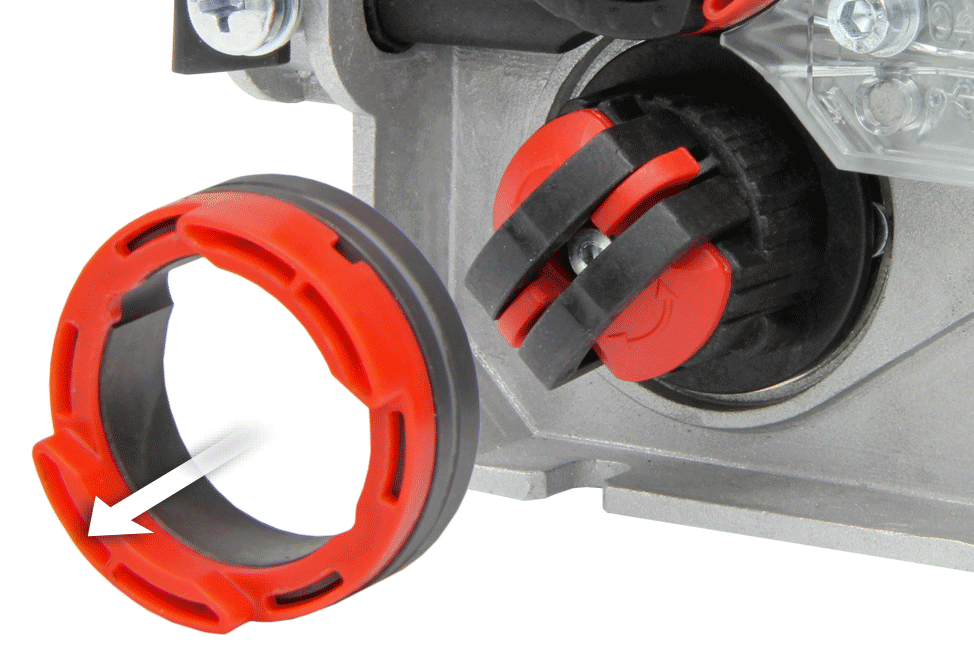

eFeed wire feeder with ball bearings and four driven drive rolls – one more step forward

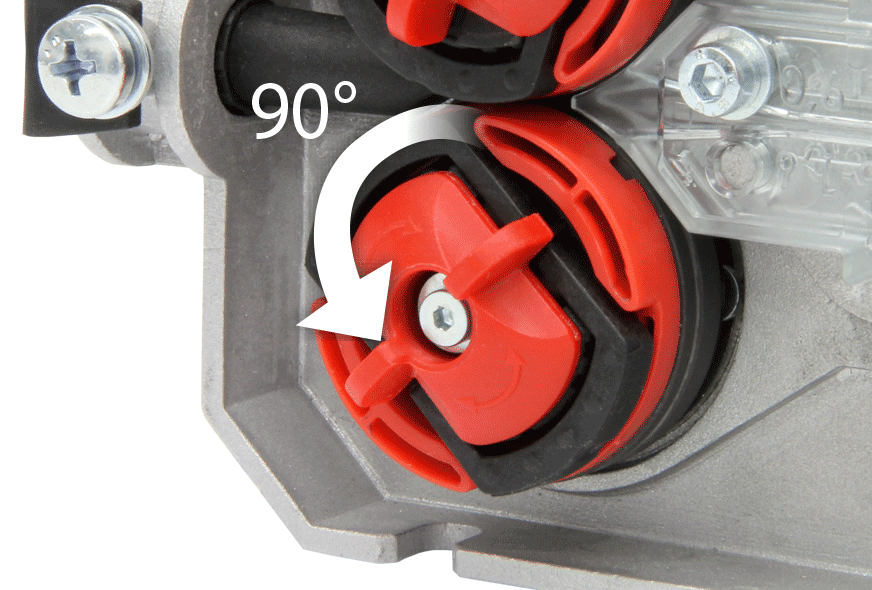

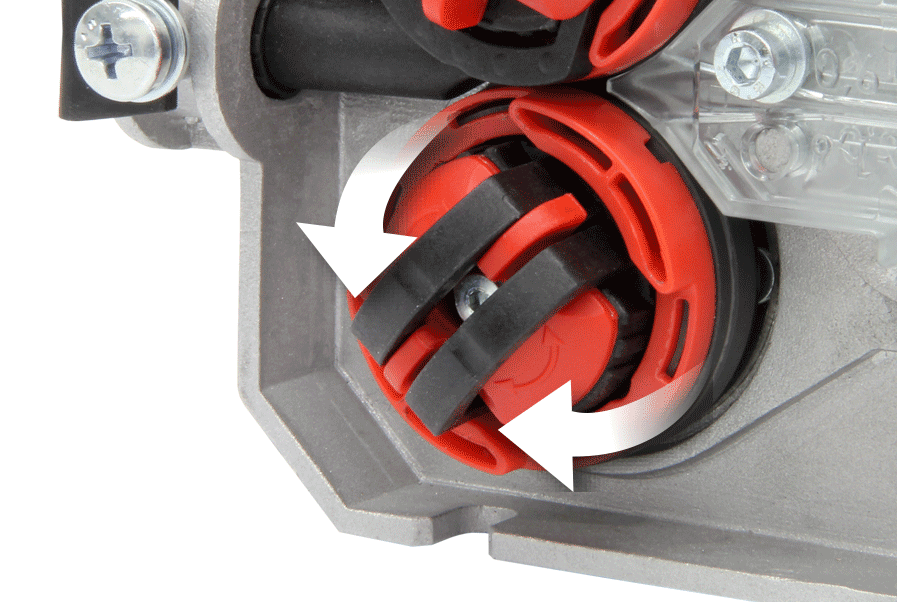

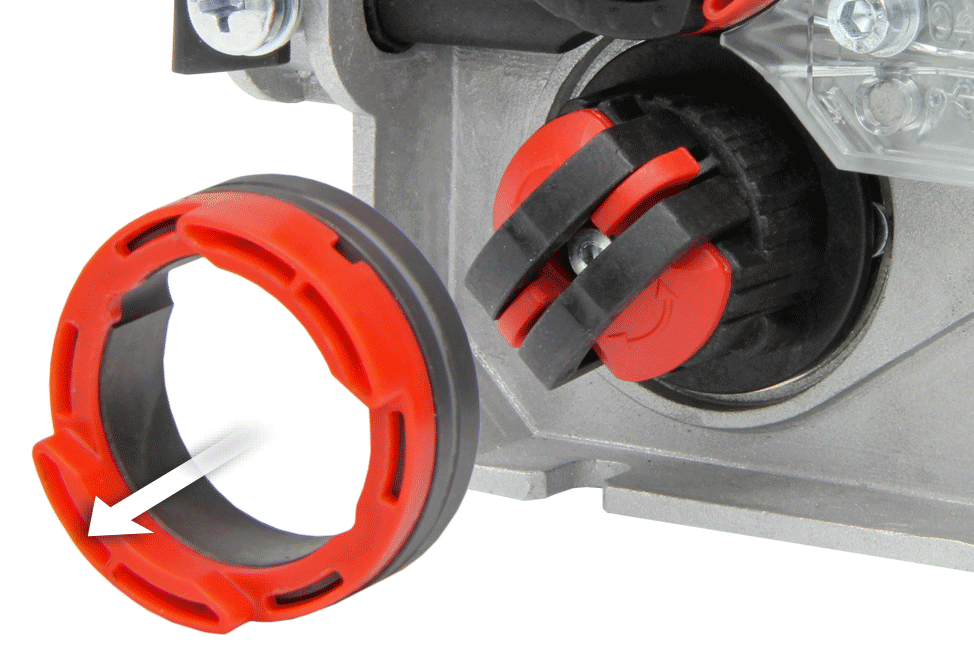

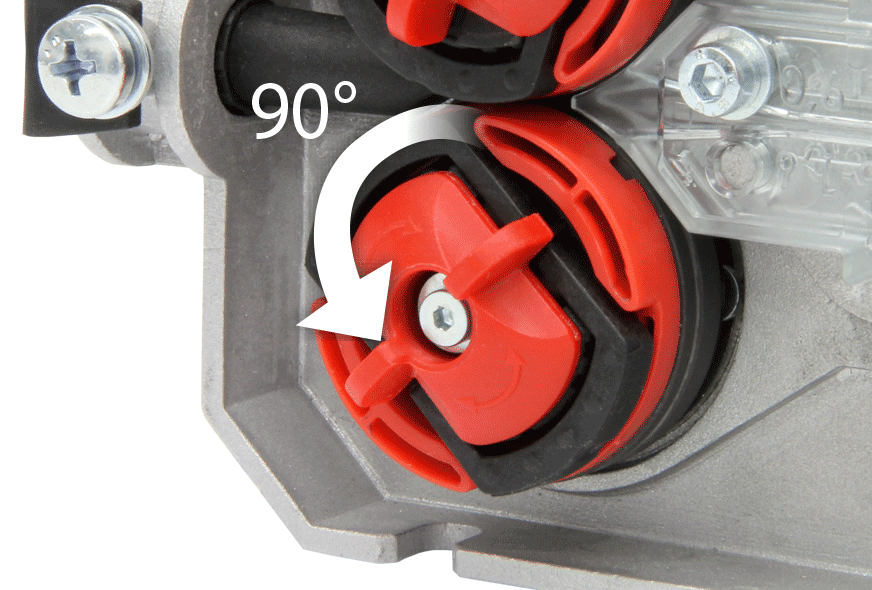

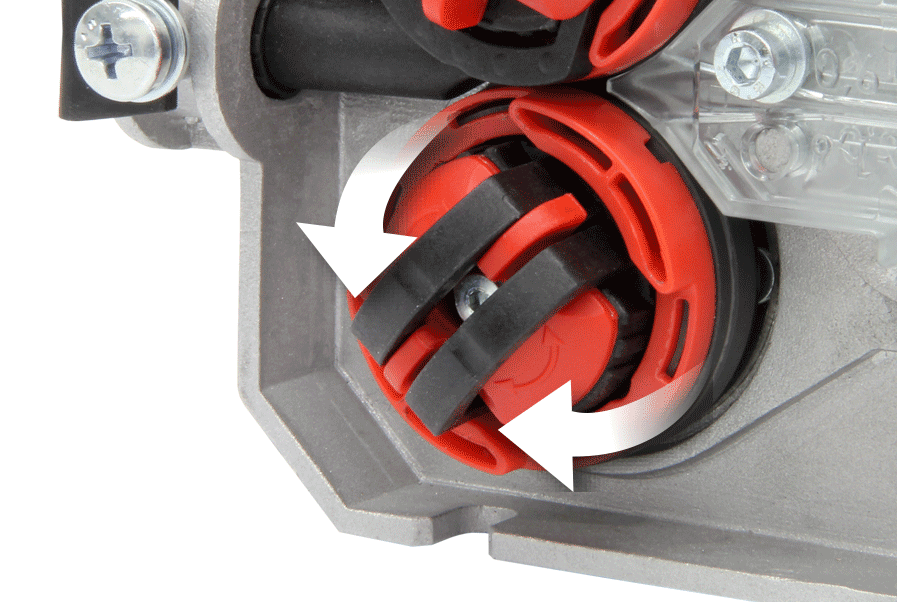

Exchange rolls in just three steps. Instantly, without tools and with captive parts

Unlock the roll fastener

Swivel out the captive roll fastener

Exchange the roll -

Colour-coded rolls – prevent confusionThe different groove diameters in the wire feed rolls are colour-coded. The grooves for aluminium (U-groove), steel, stainless steel and braze (V-groove) and flux cored wire (knurled) are indicated with coloured clips.

e.g. UNI rolls for Ø 1.0 mm to 1.2 mm with V-groove (blue/red) for stainless steel, steel

e.g. ∅ 1 mm with U-groove (blue/yellow) for aluminium

e.g. Ø 1 mm with V-groove, knurled (blue/orange) for flux cored wire

-

The eFeed wire feeder is accurate, durable and robust. The transfer is carried out cleanly via cogwheels housed in the high-quality aluminium die-cast casing. This improves the welding result even for flux cored wires and particularly soft or particularly hard, unmanageable wires.

4-wheel drive, the right way

The four wire feed rolls are centrally driven by double ball bearing drive axles.Effective inching

Wire inching takes place automatically and error-free with the eFeed. The casing can remain closed.Quick roll changes

The wire feed rolls can be changed quickly without tools: simply loosen the lock, open the bracket and remove the rolls.

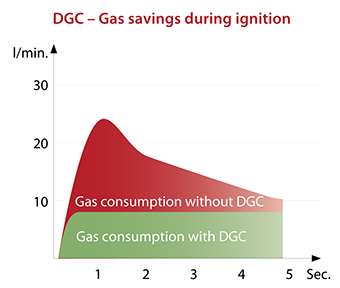

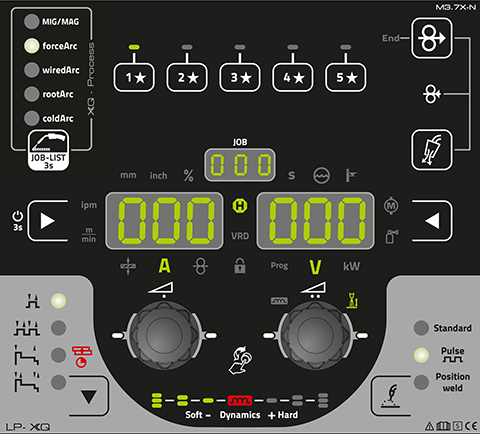

XQ series – overview of controls

-

HP-XQFor perfectionists: The HP-XQ control offers the highest level of requirement-specific setting options for the relevant welding task. The user can individually determine every detail of the welding sequence from the ignition current to the end crater program. The HP-XQ is the ideal control for professional users who leave nothing to chance for perfect results.

-

LP-XQTurn it on and start welding: Welders can use the favourites button to save their preferred settings and retrieve them. The LP-XQ control has the best parameters for the required welding sequence from the ignition current to the end crater program set up ex works. This saves training time: simply enter the operating point using the click wheel and start your work. The control is perfect for changing welding personnel, for example on construction sites and for assembly work.

-

Expert XQ 2.0Enjoy efficient working: The Expert XQ 2.0 control shows what the machine offers. The user simply needs to select the welding procedure, material, gas and wire diameter using the click wheel. The appropriate characteristic for the welding task (JOB) is immediately shown on the robust and easy-to-read LCD display and the welder is ready to go.

The control is available in the following variants and network capabilities: Expert XQ 2.0, Expert XQ 2.0 LG with integrated LAN gateway and Expert XQ 2.0 WLG with integrated LAN/Wi-Fi gateway.

EWM professional welding torch: re-discover welding

LED lighting with movement sensor:

turns on automatically when the welding torch is moved and illuminates the workpiece in the working area – for perfect visibility and best results (optional equipment).

-

Four operating variants – guaranteeing a good choice.

One standard torch and three function torches are available for the XQ series. The modern two-component grip with its rubber anti-kink device and stable ball joint is a role model for ergonomic perfection and robust EWM quality. There are different operating concepts and display options. It’s your choice!

-

RD3X function torch

Function torch with graphic display and LED light setting options:

- Welding current and wire feed speed

- Voltage correction

- Welding procedure

- Welding programs and tasks (JOBs)

- Operating mode (non-latched/latched)

- Component management: weld seams selected based on welding sequence plan

![RD3X function torch]()

-

RD2X function torch

Function torch with graphic display and LED light setting options:

- Welding current and wire feed speed

- Voltage correction

- Welding programs

![RD2X function torch]()

-

PM 2U/DX

MIG/MAG function torch with LED light setting options:

- Welding current and wire feed speed

- Voltage correction

- Program and JOB selection

![MIG/MAG function torch]()

-

Standard torch

Standard torch trigger for all MIG/MAG machines

![Standard torch]()

Standard torch

Optional torch trigger on top

![Standard torch]()

ewm Xnet

Welding 4.0 for large and small businesses. The modular system supports both welding coordination personnel and welders in their daily work.

XQ series accessories

XQ series

As you can expect from EWM, the system is well thought-out and each component tested under tough everyday conditions. Thanks to the extensive range of accessories, the welding machine can be customised to suit the individual needs of the welder and work environment. The work radius can be expanded easily. Welding parameters can be changed from any location using a remote control. The optional brackets provide space for many components. The optional cooling unit with a reinforced pump ensures that the welding torch is cooled well even over long distances and height differences.

Wire feeder accessories

-

Drive XQ

Whether manually setting the shielding gas flow, working on suspended workpieces or drum feeding: the Drive XQ wire feeder with its accompanying accessories can be easily customised for every user and every use.

-

Drive XQ IC 200

Weighing in at just 10 kg, this robust, resilient machine is perfect for work on shipyards and in hard-to-reach places.

XQ machine documents

Here you can find documentation on the XQ series. For further documents and further operating instructions, please refer to our

Online Shop

小册子

| 格式 | 语言 | 名称 | 编辑 | 信息 | |

|---|---|---|---|---|---|

| de | MIG/MAG XQ puls - Broschüre | MIG/MAG XQ puls - Broschüre | 2021-10-18 |

|

|

| de | Titan XQ puls - Broschüre | Titan XQ puls - Broschüre | 2018-12-07 |

|

|

| de | Titan XQ 400AC - Broschüre | Titan XQ 400AC - Broschüre | 2018-10-01 |

|

|

| de | PM-Schweißbrennerserie - Broschüre | PM-Standardschweißbrennner - Broschüre | 2018-11-16 |

|

|

| de | ewm Xnet - Broschüre | ewm Xnet - Broschüre | 2018-05-04 |

|

|

| en | MIG/MAG XQ puls - Brochure | MIG/MAG XQ puls - Brochure | 2021-10-18 |

|

|

| en | Titan XQ puls - Brochure | Titan XQ puls - Brochure | 2018-12-07 |

|

|

| en | Titan XQ 400AC - Brochure | Titan XQ 400AC - Brochure | 2018-10-01 |

|

|

| en | PM welding torch series - Brochure | PM welding torch series - Brochure | 2018-11-16 |

|

|

| en | ewm Xnet - Brochure | ewm Xnet - Brochure | 2018-05-04 |

|

|

| fr | MIG/MAG XQ puls - Brochure | MIG/MAG XQ puls - Brochure | 2021-10-18 |

|

|

| fr | Titan XQ puls - Brochure | Titan XQ puls - Brochure | 2018-12-07 |

|

|

| fr | Titan XQ 400AC - Brochure | Titan XQ 400AC - Brochure | 2018-10-01 |

|

|

| fr | Torches de soudage de la série PM - Brochure | Torches de soudage de la série PM - Brochure | 2018-11-16 |

|

|

| fr | ewm Xnet - Brochure | ewm Xnet - Brochure | 2018-05-04 |

|

|

| it | MIG/MAG XQ puls - Opuscolo | MIG/MAG XQ puls - Opuscolo | 2021-10-18 |

|

|

| it | Titan XQ puls - Opuscolo | Titan XQ puls - Opuscolo | 2018-12-07 |

|

|

| it | ewm Xnet - Opuscolo | ewm Xnet - Opuscolo | 2018-05-04 |

|

|

| es | MIG/MAG XQ puls - Folleto | MIG/MAG XQ puls - Folleto | 2021-10-18 |

|

|

| es | Titan XQ puls - Folleto | Titan XQ puls - Folleto | 2018-12-07 |

|

|

| es | ewm Xnet - Folleto | ewm Xnet - Folleto | 2018-05-04 |

|

|

| nl | MIG/MAG XQ puls - Brochure | MIG/MAG XQ puls - Brochure | 2021-10-18 |

|

|

| nl | Titan XQ puls - Brochure | Titan XQ puls - Brochure | 2018-12-07 |

|

|

| nl | ewm Xnet - Brochure | ewm Xnet - Brochure | 2018-05-04 |

|

|

| sv | MIG/MAG XQ puls - Broschyr | MIG/MAG XQ puls - Broschyr | 2021-10-18 |

|

|

| sv | Titan XQ puls - Broschyr | Titan XQ puls - Broschyr | 2018-12-07 |

|

|

| sv | ewm Xnet - Broschyr | ewm Xnet - Broschyr | 2018-05-04 |

|

|

| pl | MIG/MAG XQ puls - Broszura | MIG/MAG XQ puls - Broszura | 2021-10-18 |

|

|

| pl | Titan XQ puls - Broszura | Titan XQ puls - Broszura | 2018-12-07 |

|

|

| pl | ewm Xnet - Broszura | ewm Xnet - Broszura | 2018-05-04 |

|

|

| ru | MIG/MAG XQ puls - брошюра | MIG/MAG XQ puls - брошюра | 2021-10-18 |

|

|

| ru | Titan XQ puls - брошюра | Titan XQ puls - брошюра | 2018-12-07 |

|

|

| ru | ewm Xnet - брошюра | ewm Xnet - брошюра | 2018-05-04 |

|

|

| hu | Titan XQ puls - Prospektus | Titan XQ puls - Prospektus | 2018-12-07 |

|

|

| hu | ewm Xnet - Prospektus | ewm Xnet - Prospektus | 2018-05-04 |

|

|

| cs | MIG/MAG XQ puls - Brožura | MIG/MAG XQ puls - Brožura | 2021-10-18 |

|

|

| cs | Titan XQ puls - Brožura | Titan XQ puls - Brožura | 2018-12-07 |

|

|

| cs | ewm Xnet - Brožura | ewm Xnet - Brožura | 2018-05-04 |

|

|

| tr | MIG/MAG XQ puls - Broşür | MIG/MAG XQ puls - Broşür | 2021-10-18 |

|

|

| tr | Titan XQ puls - Broşür | Titan XQ puls - Broşür | 2018-12-07 |

|

|

| tr | ewm Xnet - Broşür | ewm Xnet - Broşür | 2018-05-04 |

|

|

| fi | MIG/MAG XQ puls - Esite | MIG/MAG XQ puls - Esite | 2021-10-18 |

|

|

| fi | Titan XQ puls - Esite | Titan XQ puls - Esite | 2018-12-07 |

|

|

| fi | ewm Xnet - Esite | ewm Xnet - Esite | 2018-05-04 |

|

|

| no | Titan XQ puls - Brosjyre | Titan XQ puls - Brosjyre | 2018-12-07 |

|

|

| no | ewm Xnet - Brosjyre | ewm Xnet - Brosjyre | 2018-05-04 |

|

操作手册

| 格式 | 名称 | 编辑 | 信息 | |

|---|---|---|---|---|

| Titan XQ puls - Betriebsanleitung | Titan XQ puls - Betriebsanleitung | | ||

| Drive XQ - Betriebsanleitung | Drive XQ - Betriebsanleitung | | ||

| HP XQ - Betriebsanleitung | HP XQ - Betriebsanleitung | | ||

| LP XQ - Betriebsanleitung | LP XQ - Betriebsanleitung | | ||

| Expert XQ 2.0 - Betriebsanleitung | Expert XQ 2.0 XQ - Betriebsanleitung | | ||

| Titan XQ puls - Manual | Titan XQ puls - Manual | | ||

| Drive XQ - Manual | Drive XQ - Manual | | ||

| HP XQ - Manual | HP XQ - Manual | | ||

| LP XQ - Manual | LP XQ - Manual | | ||

| Expert XQ 2.0 - Manual | Expert XQ 2.0 - Manual | | ||

| Titan XQ puls - Notice d´utilisation | Titan XQ puls - Notice d´utilisation | | ||

| Drive XQ - Notice d´utilisation | Drive XQ - Notice d´utilisation | | ||

| HP XQ - Notice d´utilisation | HP XQ - Notice d´utilisation | | ||

| LP XQ - Notice d´utilisation | LP XQ - Notice d´utilisation | | ||

| Expert XQ 2.0 - Notice d´utilisation | Expert XQ 2.0 - Notice d´utilisation | | ||

| Titan XQ puls - Manuale d´uso | Titan XQ puls - Manuale d´uso | | ||

| Drive XQ - Manuale d´uso | Drive XQ - Manuale d´uso | | ||

| HP XQ - Manuale d´uso | HP XQ - Manuale d´uso | | ||

| LP XQ - Manuale d´uso | LP XQ - Manuale d´uso | | ||

| Expert XQ 2.0 - Manuale d´uso | Expert XQ 2.0 - Manuale d´uso | | ||

| Titan XQ puls - Manual de instrucciones | Titan XQ puls - Manual de instrucciones | | ||

| Drive XQ - Manual de instrucciones | Drive XQ - Manual de instrucciones | | ||

| HP XQ - Manual de instrucciones | HP XQ - Manual de instrucciones | | ||

| LP XQ - Manual de instrucciones | LP XQ - Manual de instrucciones | | ||

| Expert XQ 2.0 - Manual de instrucciones | Expert XQ 2.0 - Manual de instrucciones | | ||

| Titan XQ puls - Bedieningshandleiding | Titan XQ puls - Bedieningshandleiding | | ||

| Drive XQ - Bedieningshandleiding | Drive XQ - Bedieningshandleiding | | ||

| HP XQ - Bedieningshandleiding | HP XQ - Bedieningshandleiding | | ||

| LP XQ - Bedieningshandleiding | LP XQ - Bedieningshandleiding | | ||

| Expert XQ 2.0 - Bedieningshandleiding | Expert XQ 2.0 - Bedieningshandleiding | | ||

| Titan XQ puls - Bruksanvisning | Titan XQ puls - Bruksanvisning | | ||

| Drive XQ - Bruksanvisning | Drive XQ - Bruksanvisning | | ||

| HP XQ - Bruksanvisning | HP XQ - Bruksanvisning | | ||

| LP XQ - Bruksanvisning | LP XQ - Bruksanvisning | | ||

| Expert XQ 2.0 - Bruksanvisning | Expert XQ 2.0 - Bruksanvisning | | ||

| Titan XQ puls - Instrukcja obsługi | Titan XQ puls - Instrukcja obsługi | | ||

| Drive XQ - Instrukcja obsługi | Drive XQ - Instrukcja obsługi | | ||

| HP XQ - Instrukcja obsługi | HP XQ - Instrukcja obsługi | | ||

| LP XQ - Instrukcja obsługi | LP XQ - Instrukcja obsługi | | ||

| Expert XQ 2.0 - Instrukcja obsługi | Expert XQ 2.0 - Instrukcja obsługi | | ||

| Titan XQ puls - Руководство по эксплуатации | Titan XQ puls - Руководство по эксплуатации | | ||

| Drive XQ - Руководство по эксплуатации | Drive XQ - Руководство по эксплуатации | | ||

| HP XQ - Руководство по эксплуатации | HP XQ - Руководство по эксплуатации | | ||

| LP XQ - Руководство по эксплуатации | LP XQ - Руководство по эксплуатации | | ||

| Expert XQ 2.0 - Руководство по эксплуатации | Expert XQ 2.0 - Руководство по эксплуатации | | ||

| Titan XQ puls - Üzemeltetési utasítás | Titan XQ puls - Üzemeltetési utasítás | | ||

| Drive XQ - Üzemeltetési utasítás | Drive XQ - Üzemeltetési utasítás | | ||

| HP XQ - Üzemeltetési utasítás | HP XQ - Üzemeltetési utasítás | | ||

| LP XQ - Üzemeltetési utasítás | LP XQ - Üzemeltetési utasítás | | ||

| Expert XQ 2.0 - Üzemeltetési utasítás | Expert XQ 2.0 - Üzemeltetési utasítás | | ||

| Titan XQ puls - Návody k obsluze | Titan XQ puls - Návody k obsluze | | ||

| Drive XQ - Návody k obsluze | Drive XQ - Návody k obsluze | | ||

| HP XQ - Návody k obsluze | HP XQ - Návody k obsluze | | ||

| LP XQ - Návody k obsluze | LP XQ - Návody k obsluze | | ||

| Expert XQ 2.0 - Návody k obsluze | Expert XQ 2.0 - Návody k obsluze | | ||

| Titan XQ puls - Kullanim kilavuzu | Titan XQ puls - Kullanim kilavuzu | | ||

| Drive XQ - Kullanim kilavuzu | Drive XQ - Kullanim kilavuzu | | ||

| HP XQ - Kullanim kilavuzu | HP XQ - Kullanim kilavuzu | | ||

| LP XQ - Kullanim kilavuzu | LP XQ - Kullanim kilavuzu | | ||

| Expert XQ 2.0 - Kullanim kilavuzu | Expert XQ 2.0 - Kullanim kilavuzu | | ||

| Titan XQ puls - Käyttöohje | Titan XQ puls - Käyttöohje | | ||

| Drive XQ - Käyttöohje | Drive XQ - Käyttöohje | | ||

| HP XQ - Käyttöohje | HP XQ - Käyttöohje | | ||

| LP XQ - Käyttöohje | LP XQ - Käyttöohje | | ||

| Expert XQ 2.0 - Käyttöohje | Expert XQ 2.0 - Käyttöohje | | ||

| HP XQ - Manual de instruções | HP XQ - Manual de instruções | | ||

| LP XQ - Manual de instruções | LP XQ - Manual de instruções | | ||

| Expert XQ 2.0 - Manual de instruções | Expert XQ 2.0 - Manual de instruções | |

Contact

-

-

-

Technical data – Phoenix XQ 355 puls

适用 Phoenix XQ 355 puls D 焊接电流设置范围 5 A - 350 A 暂载率 40 °C 350 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 480 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 18.8 kVA 效率 90 % 功率消耗 Pi 23 W 防护等级 IP23 EMC 等级 A 625 mm x 298 mm x 531 mm 24.6 inch x 11.7 inch x 20.9 inch 重量 39.4 kg / 86.9 lbs 标准 IEC 60974-1, -10 CL.A -

Technical data – Phoenix XQ 405 puls

适用 Phoenix XQ 405 puls D 焊接电流设置范围 5 A - 400 A 暂载率 40 °C 400 A / 60 % 350 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 480 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 23.2 kVA 效率 90 % 功率消耗 Pi 23 W 防护等级 IP23 EMC 等级 A 625 mm x 298 mm x 531 mm 24.6 inch x 11.7 inch x 20.9 inch 重量 39.4 kg / 86.9 lbs 标准 IEC 60974-1, -10 CL.A -

Technical data – Phoenix XQ 505 puls

适用 Phoenix XQ 505 puls D 焊接电流设置范围 5 A - 500 A 暂载率 40 °C 500 A / 40 % 430 A / 60 % 370 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 480 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 33.2 kVA 效率 90 % 功率消耗 Pi 23 W 防护等级 IP23 EMC 等级 A 625 mm x 298 mm x 531 mm 24.6 inch x 11.7 inch x 20.9 inch 重量 42.7 kg / 94.2 lbs 标准 IEC 60974-1, -10 CL.A -

Technical data – cool50-2 U40

型号 cool50-2 U40 电网电压 1 电网频率 50 Hz / 60 Hz 电网电压 1 x 400 V 1000 W 3.5 bar 水箱容量 5.5 l IP23 695 mm x 298 mm x 329 mm 27.4 inch x 11.7 inch x 13 inch 重量 21 kg / 46.3 lbs 标准 IEC 60974-1, -2, -10 CL.A High-performance cooling unit for water-cooled welding torches – also available with reinforced pump for extra-long hose packages.

-

Technical data – cool50-2 U42

型号 cool50-2 U42 电网电压 1 电网频率 50 Hz / 60 Hz 电网电压 1 x 400 V 1000 W 4.5 bar 水箱容量 5.5 l IP23 695 mm x 298 mm x 329 mm 27.4 inch x 11.7 inch x 13 inch 重量 21 kg / 46.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Cooling unit with reinforced pump for use with extra-long hose packages

-

-

Phoenix XQ puls welding processes

- Welding process finder

rootArc® XQ/rootArc® puls XQ

rootArc® XQ/rootArc® puls XQ forceArc® XQ/forceArc® puls XQ

forceArc® XQ/forceArc® puls XQ Positionweld XQ for aluminium

Positionweld XQ for aluminium superPuls

superPuls Puls

Puls Standard (MIG/MAG)

Standard (MIG/MAG)- TIG and MMA welding

- Gouging

-

-

-

-

Technical data – Taurus XQ 355 Synergic

适用 Taurus XQ 355 Synergic D 焊接电流设置范围 5 A - 350 A 暂载率 40 °C 350 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 480 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 18.8 kVA 效率 90 % 功率消耗 Pi 23 W 防护等级 IP23 EMC 等级 A 625 mm x 298 mm x 531 mm 24.6 inch x 11.7 inch x 20.9 inch 重量 39.4 kg / 86.9 lbs 标准 IEC 60974-1, -10 CL.A -

Technical data – Taurus XQ 405 Synergic

适用 Taurus XQ 405 Synergic D 焊接电流设置范围 5 A - 400 A 暂载率 40 °C 400 A / 60 % 350 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 480 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 23.2 kVA 效率 90 % 功率消耗 Pi 23 W 防护等级 IP23 EMC 等级 A 625 mm x 298 mm x 531 mm 24.6 inch x 11.7 inch x 20.9 inch 重量 39.4 kg / 86.9 lbs 标准 IEC 60974-1, -10 CL.A -

Technical data – Taurus XQ 505 Synergic

适用 Taurus XQ 505 Synergic D 焊接电流设置范围 5 A - 500 A 暂载率 40 °C 500 A / 40 % 430 A / 60 % 370 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 480 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 33.2 kVA 效率 90 % 功率消耗 Pi 23 W 防护等级 IP23 EMC 等级 A 625 mm x 298 mm x 531 mm 24.6 inch x 11.7 inch x 20.9 inch 重量 42.7 kg / 94.2 lbs 标准 IEC 60974-1, -10 CL.A -

Technical data – cool50-2 U40

型号 cool50-2 U40 电网电压 1 电网频率 50 Hz / 60 Hz 电网电压 1 x 400 V 1000 W 3.5 bar 水箱容量 5.5 l IP23 695 mm x 298 mm x 329 mm 27.4 inch x 11.7 inch x 13 inch 重量 21 kg / 46.3 lbs 标准 IEC 60974-1, -2, -10 CL.A High-performance cooling unit for water-cooled welding torches – also available with reinforced pump for extra-long hose packages.

-

Technical data – cool50-2 U42

型号 cool50-2 U42 电网电压 1 电网频率 50 Hz / 60 Hz 电网电压 1 x 400 V 1000 W 4.5 bar 水箱容量 5.5 l IP23 695 mm x 298 mm x 329 mm 27.4 inch x 11.7 inch x 13 inch 重量 21 kg / 46.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Cooling unit with reinforced pump for use with extra-long hose packages

-

-

Taurus XQ Synergic welding processes

![XQ welding process]()

- Welding process finder

rootArc® XQ

rootArc® XQ forceArc® XQ

forceArc® XQ superPuls

superPuls Standard (MIG/MAG)

Standard (MIG/MAG)- TIG and MMA welding

- Gouging

-

-

-

-

Technical data – Taurus XQ 355 Basic

适用 Taurus XQ 355 Basic D 焊接电流设置范围 5 A - 350 A 暂载率 40 °C 350 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 480 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 18.8 kVA 效率 90 % 功率消耗 Pi 23 W 防护等级 IP23 EMC 等级 A 625 mm x 298 mm x 531 mm 24.6 inch x 11.7 inch x 20.9 inch 重量 39.4 kg / 86.9 lbs 标准 IEC 60974-1, -10 CL.A -

Technical data – Taurus XQ 405 Basic

适用 Taurus XQ 405 Basic D 焊接电流设置范围 5 A - 400 A 暂载率 40 °C 400 A / 60 % 350 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 480 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 23.2 kVA 效率 90 % 功率消耗 Pi 23 W 防护等级 IP23 EMC 等级 A 625 mm x 298 mm x 531 mm 24.6 inch x 11.7 inch x 20.9 inch 重量 39.4 kg / 86.9 lbs 标准 IEC 60974-1, -10 CL.A -

Technical data – Taurus XQ 505 Basic

适用 Taurus XQ 505 Basic D 焊接电流设置范围 5 A - 500 A 暂载率 40 °C 500 A / 40 % 430 A / 60 % 370 A / 100 % 空载电压 82 V 3 x 380 V - 400 V 3 x 440 V - 480 V -25 % 直到 +20 % 电网频率 50 Hz / 60 Hz 推荐配电发电机功率 33.2 kVA 效率 90 % 功率消耗 Pi 23 W 防护等级 IP23 EMC 等级 A 625 mm x 298 mm x 531 mm 24.6 inch x 11.7 inch x 20.9 inch 重量 42.7 kg / 94.2 lbs 标准 IEC 60974-1, -10 CL.A -

Technical data – cool50-2 U40

型号 cool50-2 U40 电网电压 1 电网频率 50 Hz / 60 Hz 电网电压 1 x 400 V 1000 W 3.5 bar 水箱容量 5.5 l IP23 695 mm x 298 mm x 329 mm 27.4 inch x 11.7 inch x 13 inch 重量 21 kg / 46.3 lbs 标准 IEC 60974-1, -2, -10 CL.A High-performance cooling unit for water-cooled welding torches – also available with reinforced pump for extra-long hose packages.

-

Technical data – cool50-2 U42

型号 cool50-2 U42 电网电压 1 电网频率 50 Hz / 60 Hz 电网电压 1 x 400 V 1000 W 4.5 bar 水箱容量 5.5 l IP23 695 mm x 298 mm x 329 mm 27.4 inch x 11.7 inch x 13 inch 重量 21 kg / 46.3 lbs 标准 IEC 60974-1, -2, -10 CL.A Cooling unit with reinforced pump for use with extra-long hose packages

-

-

Taurus XQ Basic welding processes

![XQ welding process]()

- Welding process finder

Standard (MIG/MAG)

Standard (MIG/MAG)- TIG and MMA welding

- Gouging

-

-

Overview of the EWM XQ series

- / rootArc® XQ/rootArc® puls XQ

- / forceArc® XQ/forceArc® puls XQ

- / Positionweld for aluminium

- / Standard (MIG/MAG)

- / Pulse

- / superPuls

- / TIG

- / MMA

- / Gouging

- / rootArc® XQ

- / forceArc® XQ

- / Standard (MIG/MAG)

- / superPuls

- / TIG

- / MMA

- / Gouging

- / Standard (MIG/MAG)

- / TIG

- / MMA

- / Gouging

The XQ welding processes:

rootArc XQ/rootArc puls XQ – Perfect root welding, easy-to-execute filler and final passes

forceArc XQ/forceArc puls XQ – Powerful high-performance arc with deep penetration

Standard (MIG/MAG) – Perfect short and spray arcs

Pulse – Low-spatter pulsed arc

Positionweld – Simple positional welding without the “Christmas tree” technique

superPuls – Heat-reduced interval welding between two operating points (high-current and low-current phases freely adjustable)

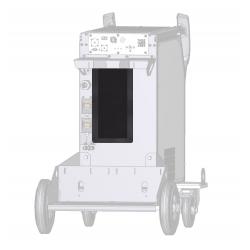

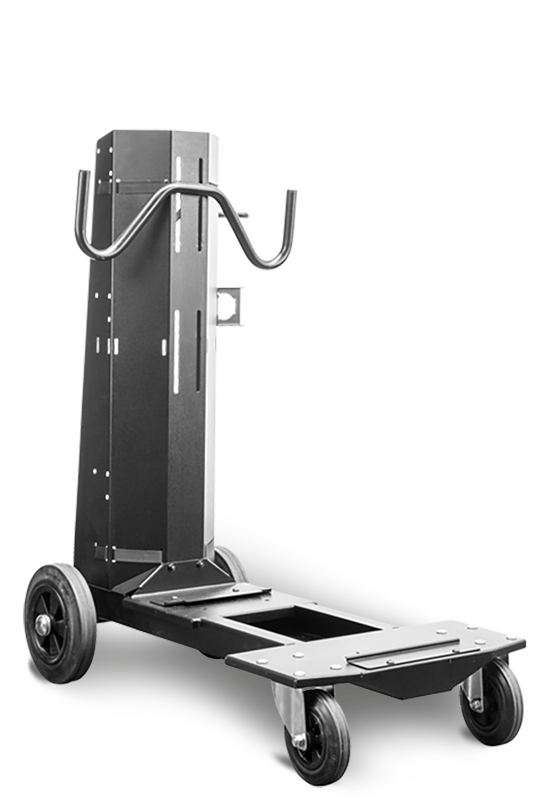

XQ series – Modular casing system for workstations in all kinds of environments

XQ – Modular casing system for workstations in all kinds of environments. Gas or water cooled Flexible design: suitable for use both in production or as a mobile machine on the construction site or job. Portable or mobile on a Trolly. Space-saving and lightweight design guarantees flexibility and mobility.

XQ series – Modular casing system for workstations in all kinds of environments

Different Trolly models Workshop or construction site Trolly? There are three models to choose from:

-

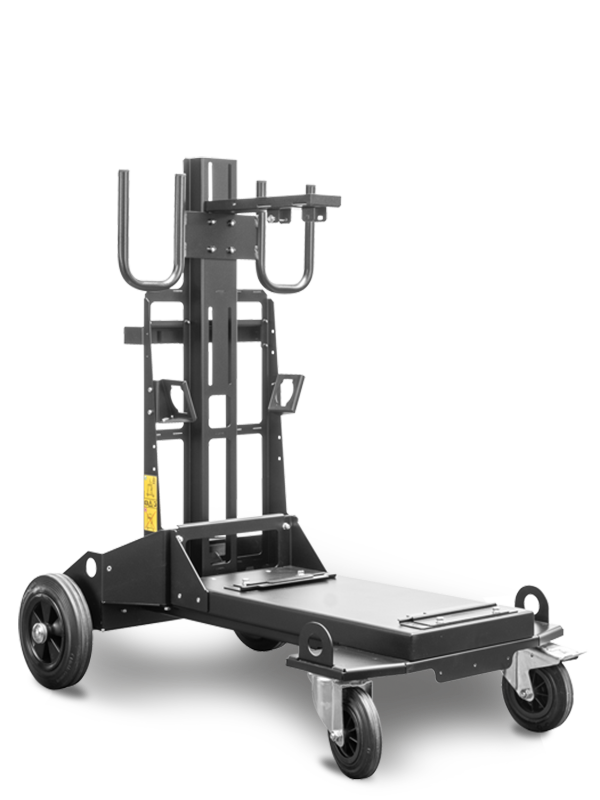

Trolly XQ 55-5

- Transport cart, 4 rollers

- Solid, stable design

- For transporting a power source, a cooling unit and a shielding gas cylinder

- Optional torch holder available

-

Trolly 55-6

- Transport cart, 4 rollers

- Solid, stable design

- For transporting a power source, a cooling unit and one or two shielding gas cylinders

- Can be lifted by crane as standard

- Supplied with braking rollers

-

Trolly 35-6

- Transport cart, 2 rollers

- Solid, stable design

- Best suited to particularly uneven areas

- For holding a power source and a wire feeder

Drive XQ wire feeders – great options to make life easier

-

Drive XQ wire feeder

At just 13 kg (excl. wire spool) and with a balanced, ergonomic handle, the Drive XQ wire feeder is the perfect companion for impassable scaffolding, hard-to-reach work spaces or large components – it can even fit through manholes.

-

MIG/MAG wire feeder for XQ welding machines

- Suitable for 200-mm or 300-mm wire spools

- Easy to transport thanks to its low weight and compact design

- Interior lighting

- Stable base construction (continuous cast aluminium) with sliding rails as standard

- Transparent protective cap – welding parameters visible at all times

- Robust electronics protected in a dust-free area

- Protected arrangement of connections for intermediate hose packages and control cables

- Non-specialist staff can change hose packages without tools

- eFeed: innovative 4-roll drive (quadruple meshing)

- Equipped with 1.0–1.2-mm UNI rolls for low to high-alloy steel

![Drive XQ IC 200 wire feeder]()

-

DGC – electronic gas flow control: Save gas with ease and accuracy (optional)

- Prevents welding errors caused by too much or too little gas

- Efficiency through gas savings thanks to accurate settings

- Fully reproducible thanks to digital configuration and saving to the respective JOB (welding task)

- Constant gas flow rate thanks to electronic adjustment

- Digital display of nominal and actual gas flow rate values in l/min

- Extremely advantageous with long hose packages, e.g. for shipbuilding and steel construction

- No gas blast with turbulence when igniting the arc as the electrical valve opens and closes gently

![DGC graphics]()

-

WRS – wire reserve sensor: no unexpected occurrences during welding

- The sensor warns at 10% residual quantity of the wire spool by means of a control lamp.

- It reduces the risk of seam errors occurring due to the wire running out during welding.

- A spool change can be planned in advance, which reduces downtime.

![XQ series Drive 4]()

-

WHS – wire spool heater: regulated heat for better seam quality (optional)

- The wire is pre-heated, which reduces the build-up of moisture on the welding wire.

- The temperature is regulated at 50 °C (adjustable).

- The welding results are perfect, especially for aluminium.

![XQ series Drive 4]()

-

Electrode holder connection (optional)

- Ideal for MMA welding

- Ideal for gouging

![XQ series Drive 4]()

-

-

Drive XQ IC 200 wire feeder

Weighing in at just 10 kg, this robust, resilient machine is perfect for work on shipyards and in hard-to-reach places.

-

Drive XQ IC 200 wire feeder

- MIG/MAG wire feeder for XQ welding machines

- Powerful, high-precision EWM eFeed 4-roll wire feeder to reliably feed all solid and flux cored wires

- Easy to transport thanks to its low weight and compact design

- Suitable for 5-kg D200 wire spools

- Lightweight and robust design, ideal for shipyard applications

- Robust electronics protected in a dust-free area

- Optionally with integrated flow meter

![Drive XQ IC 200 wire feeder]()

-

Flow meter (optional)

Optional analogue gas flow rate adjustment with gas flow meter

- Flow meter for setting the shielding gas flow manually

- Precise setting and checking of the gas quantity at the welding site

- Extremely advantageous with long hose packages, e.g. for shipbuilding and steel construction

![Flow meter]()

-

Securely connected

Retrofitting option: Water cooling for wire feeder

- Key switch – control shut-off to protect against operator error

- Tool-free changing of intermediate hose packages

- Easy-to-access, internal hose package connections, fully protected thanks to cover cap

- Strain-relieved hose package thanks to quick connect coupling system

![Cool hose package connections]()

-

Handle/ON TG D12 (optional)

Retrofitting option: Carrying handle and strap

![Handle/ON TG D12]()

-

Transparent cover lens

Transparent cover lens for wire feed controls

- Cover lens made of transparent plastic

- Protects the controls against dirt and damage

- Operation still possible thanks to recesses for the operating knobs

![Cover lens]()

-

PS drive D12 (optional)

Pivot support (360°) for wire feeders

- Wire feeder pivots 360° on the welding machine

- Increased working radius thanks to rotatability

- Wire feeder can be mounted and removed without tools

- When using on welding machines with casing type F.0006, option ON PS F06 1D01 must be present

- For use on Trolly XQ 55-5, option ON PS Trolly XQ 55-5 is required

- For use on Trolly 55-6, cross arm ON PS Trolly 55-5/55-6 is required

![PS drive D12]()

-

Wheel set – facilitates work at frequently changing welding sites (optional)

Wheel assembly kit

- Wheel set – facilitates work at frequently changing welding sites

![Wheel assembly kit]()

-

eFeed wire feeder – full traction

-

eFeed wire feeder with ball bearings and four driven drive rolls – one more step forward

Exchange rolls in just three steps. Instantly, without tools and with captive parts

Unlock the roll fastener

Swivel out the captive roll fastener

Exchange the roll -

Colour-coded rolls – prevent confusionThe different groove diameters in the wire feed rolls are colour-coded. The grooves for aluminium (U-groove), steel, stainless steel and braze (V-groove) and flux cored wire (knurled) are indicated with coloured clips.

e.g. UNI rolls for Ø 1.0 mm to 1.2 mm with V-groove (blue/red) for stainless steel, steel

e.g. ∅ 1 mm with U-groove (blue/yellow) for aluminium

e.g. Ø 1 mm with V-groove, knurled (blue/orange) for flux cored wire

-

The eFeed wire feeder is accurate, durable and robust. The transfer is carried out cleanly via cogwheels housed in the high-quality aluminium die-cast casing. This improves the welding result even for flux cored wires and particularly soft or particularly hard, unmanageable wires.

4-wheel drive, the right way

The four wire feed rolls are centrally driven by double ball bearing drive axles.Effective inching

Wire inching takes place automatically and error-free with the eFeed. The casing can remain closed.Quick roll changes

The wire feed rolls can be changed quickly without tools: simply loosen the lock, open the bracket and remove the rolls.

XQ series – Overview of controls

-

HP-XQFor perfectionists: The HP-XQ control offers the highest level of requirement-specific settings options for the relevant welding task. The user can individually determine every detail of the welding sequence, from the ignition current to the end crater program. The HP-XQ is the ideal control for professional users who leave nothing to chance for perfect results.

-

LP-XQSwitch it on and start welding: Welders can use the favourites button to save their preferred settings and retrieve them. The LP-XQ control has the best parameters for every required welding sequence set up ex works – from the ignition current to the end crater program. This saves training time: simply set the operating point using the click wheel and start working. This control is perfect when the welding personnel are constantly changing, for example on construction sites and for assembly work.

-

Expert XQ 2.0Enjoy efficient working: The Expert XQ 2.0 control shows what the machine can do. The user simply needs to select the welding procedure, material, gas and wire diameter using the click wheel. The appropriate characteristic for the welding task (JOB) is immediately shown on the robust and easy-to-read LCD display and the welder is ready to go.

The control is available in the following variants and with the following networking capabilities: Expert XQ 2.0, Expert XQ 2.0 LG with integrated LAN gateway and Expert XQ 2.0 WLG with integrated LAN/Wi-Fi gateway.

EWM professional welding torch: re-discover welding

LED lighting with movement sensor:

turns on automatically when the welding torch is moved and illuminates the workpiece in the working area – for perfect visibility and best results (optional equipment).

-

Four operating variants – guaranteeing a good choice.

One standard torch and three function torches are available for the XQ series. The modern two-component grip with its rubber anti-kink device and stable ball joint is a role model for ergonomic perfection and robust EWM quality. There are different operating concepts and display options. It’s your choice!

-

RD3X function torch

Function torch with graphic display and LED light setting options:

- Welding current and wire feed speed

- Voltage correction

- Welding procedure

- Welding programs and tasks (JOBs)

- Operating mode (non-latched/latched)

- Component management: weld seams selected based on welding sequence plan

![RD3X function torch]()

-

RD2X function torch

Function torch with graphic display and LED light setting options:

- Welding current and wire feed speed

- Voltage correction

- Welding programs

![RD2X function torch]()

-

PM 2U/DX

MIG/MAG function torch with LED light setting options:

- Welding current and wire feed speed

- Voltage correction

- Program and JOB selection

![MIG/MAG function torch]()

-

Standard torch

Standard torch trigger for all MIG/MAG machines

![Standard torch]()

Standard torch

Optional torch trigger on top

![Standard torch]()

ewm Xnet

Welding 4.0 for large and small businesses. The modular system supports both welding coordination personnel and welders in their daily work.

XQ series modular accessories

XQ series

As you can expect from EWM, the system is well thought-out and each component has been tested under tough everyday conditions. Thanks to the extensive range of accessories, the welding machine can be customised to suit the individual needs of the welder and work environment. The working radius can be expanded easily. Welding parameters can be changed from any location using a remote control. The optional brackets provide space for many components. The optional cooling unit with a reinforced pump ensures that the welding torch is cooled well even over long distances and height differences.

Wire feeder accessories

-

Drive XQ

Whether manually setting the shielding gas flow, working on suspended workpieces or drum feeding: the Drive XQ wire feeder with its accompanying accessories can be easily customised for every user and every use.

-

Drive XQ IC 200

Weighing in at just 10 kg, this robust, resilient machine is perfect for work on shipyards and in hard-to-reach places.

XQ machine documents

Here you can find documentation on the XQ series. For further documents and further operating instructions, please refer to our

Online Shop

小册子

| 格式 | 语言 | 名称 | 编辑 | 信息 | |

|---|---|---|---|---|---|

| de | MIG/MAG XQ puls - Broschüre | MIG/MAG XQ puls - Broschüre | 2021-10-18 |

|

|

| de | Titan XQ puls - Broschüre | Titan XQ puls - Broschüre | 2018-12-07 |

|

|

| de | Titan XQ 400AC - Broschüre | Titan XQ 400AC - Broschüre | 2018-10-01 |

|

|

| de | PM-Schweißbrennerserie - Broschüre | PM-Standardschweißbrennner - Broschüre | 2018-11-16 |

|

|

| de | ewm Xnet - Broschüre | ewm Xnet - Broschüre | 2018-05-04 |

|

|

| en | MIG/MAG XQ puls - Brochure | MIG/MAG XQ puls - Brochure | 2021-10-18 |

|

|

| en | Titan XQ puls - Brochure | Titan XQ puls - Brochure | 2018-12-07 |

|

|

| en | Titan XQ 400AC - Brochure | Titan XQ 400AC - Brochure | 2018-10-01 |

|

|

| en | PM welding torch series - Brochure | PM welding torch series - Brochure | 2018-11-16 |

|

|

| en | ewm Xnet - Brochure | ewm Xnet - Brochure | 2018-05-04 |

|

|

| fr | MIG/MAG XQ puls - Brochure | MIG/MAG XQ puls - Brochure | 2021-10-18 |

|

|

| fr | Titan XQ puls - Brochure | Titan XQ puls - Brochure | 2018-12-07 |

|

|

| fr | Titan XQ 400AC - Brochure | Titan XQ 400AC - Brochure | 2018-10-01 |

|

|

| fr | Torches de soudage de la série PM - Brochure | Torches de soudage de la série PM - Brochure | 2018-11-16 |

|

|

| fr | ewm Xnet - Brochure | ewm Xnet - Brochure | 2018-05-04 |

|

|

| it | MIG/MAG XQ puls - Opuscolo | MIG/MAG XQ puls - Opuscolo | 2021-10-18 |

|

|

| it | Titan XQ puls - Opuscolo | Titan XQ puls - Opuscolo | 2018-12-07 |

|

|

| it | ewm Xnet - Opuscolo | ewm Xnet - Opuscolo | 2018-05-04 |

|

|

| es | MIG/MAG XQ puls - Folleto | MIG/MAG XQ puls - Folleto | 2021-10-18 |

|

|

| es | Titan XQ puls - Folleto | Titan XQ puls - Folleto | 2018-12-07 |

|

|

| es | ewm Xnet - Folleto | ewm Xnet - Folleto | 2018-05-04 |

|

|

| nl | MIG/MAG XQ puls - Brochure | MIG/MAG XQ puls - Brochure | 2021-10-18 |

|

|

| nl | Titan XQ puls - Brochure | Titan XQ puls - Brochure | 2018-12-07 |

|

|

| nl | ewm Xnet - Brochure | ewm Xnet - Brochure | 2018-05-04 |

|

|

| sv | MIG/MAG XQ puls - Broschyr | MIG/MAG XQ puls - Broschyr | 2021-10-18 |

|

|

| sv | Titan XQ puls - Broschyr | Titan XQ puls - Broschyr | 2018-12-07 |

|

|

| sv | ewm Xnet - Broschyr | ewm Xnet - Broschyr | 2018-05-04 |

|

|

| pl | MIG/MAG XQ puls - Broszura | MIG/MAG XQ puls - Broszura | 2021-10-18 |

|

|

| pl | Titan XQ puls - Broszura | Titan XQ puls - Broszura | 2018-12-07 |

|

|

| pl | ewm Xnet - Broszura | ewm Xnet - Broszura | 2018-05-04 |

|

|

| ru | MIG/MAG XQ puls - брошюра | MIG/MAG XQ puls - брошюра | 2021-10-18 |

|

|

| ru | Titan XQ puls - брошюра | Titan XQ puls - брошюра | 2018-12-07 |

|

|

| ru | ewm Xnet - брошюра | ewm Xnet - брошюра | 2018-05-04 |

|

|

| hu | Titan XQ puls - Prospektus | Titan XQ puls - Prospektus | 2018-12-07 |

|

|

| hu | ewm Xnet - Prospektus | ewm Xnet - Prospektus | 2018-05-04 |

|

|

| cs | MIG/MAG XQ puls - Brožura | MIG/MAG XQ puls - Brožura | 2021-10-18 |

|

|

| cs | Titan XQ puls - Brožura | Titan XQ puls - Brožura | 2018-12-07 |

|

|

| cs | ewm Xnet - Brožura | ewm Xnet - Brožura | 2018-05-04 |

|

|

| tr | MIG/MAG XQ puls - Broşür | MIG/MAG XQ puls - Broşür | 2021-10-18 |

|

|

| tr | Titan XQ puls - Broşür | Titan XQ puls - Broşür | 2018-12-07 |

|

|

| tr | ewm Xnet - Broşür | ewm Xnet - Broşür | 2018-05-04 |

|

|

| fi | MIG/MAG XQ puls - Esite | MIG/MAG XQ puls - Esite | 2021-10-18 |

|

|

| fi | Titan XQ puls - Esite | Titan XQ puls - Esite | 2018-12-07 |

|

|

| fi | ewm Xnet - Esite | ewm Xnet - Esite | 2018-05-04 |

|

|

| no | Titan XQ puls - Brosjyre | Titan XQ puls - Brosjyre | 2018-12-07 |

|

|

| no | ewm Xnet - Brosjyre | ewm Xnet - Brosjyre | 2018-05-04 |

|

操作手册

| 格式 | 名称 | 编辑 | 信息 | |

|---|---|---|---|---|

| Titan XQ puls - Betriebsanleitung | Titan XQ puls - Betriebsanleitung | | ||

| Drive XQ - Betriebsanleitung | Drive XQ - Betriebsanleitung | | ||

| HP XQ - Betriebsanleitung | HP XQ - Betriebsanleitung | | ||

| LP XQ - Betriebsanleitung | LP XQ - Betriebsanleitung | | ||

| Expert XQ 2.0 - Betriebsanleitung | Expert XQ 2.0 XQ - Betriebsanleitung | | ||

| Titan XQ puls - Manual | Titan XQ puls - Manual | | ||

| Drive XQ - Manual | Drive XQ - Manual | | ||

| HP XQ - Manual | HP XQ - Manual | | ||

| LP XQ - Manual | LP XQ - Manual | | ||

| Expert XQ 2.0 - Manual | Expert XQ 2.0 - Manual | | ||

| Titan XQ puls - Notice d´utilisation | Titan XQ puls - Notice d´utilisation | | ||

| Drive XQ - Notice d´utilisation | Drive XQ - Notice d´utilisation | | ||

| HP XQ - Notice d´utilisation | HP XQ - Notice d´utilisation | | ||

| LP XQ - Notice d´utilisation | LP XQ - Notice d´utilisation | | ||

| Expert XQ 2.0 - Notice d´utilisation | Expert XQ 2.0 - Notice d´utilisation | | ||

| Titan XQ puls - Manuale d´uso | Titan XQ puls - Manuale d´uso | | ||

| Drive XQ - Manuale d´uso | Drive XQ - Manuale d´uso | | ||

| HP XQ - Manuale d´uso | HP XQ - Manuale d´uso | | ||

| LP XQ - Manuale d´uso | LP XQ - Manuale d´uso | | ||

| Expert XQ 2.0 - Manuale d´uso | Expert XQ 2.0 - Manuale d´uso | | ||

| Titan XQ puls - Manual de instrucciones | Titan XQ puls - Manual de instrucciones | | ||

| Drive XQ - Manual de instrucciones | Drive XQ - Manual de instrucciones | | ||

| HP XQ - Manual de instrucciones | HP XQ - Manual de instrucciones | | ||

| LP XQ - Manual de instrucciones | LP XQ - Manual de instrucciones | | ||

| Expert XQ 2.0 - Manual de instrucciones | Expert XQ 2.0 - Manual de instrucciones | | ||

| Titan XQ puls - Bedieningshandleiding | Titan XQ puls - Bedieningshandleiding | | ||

| Drive XQ - Bedieningshandleiding | Drive XQ - Bedieningshandleiding | | ||

| HP XQ - Bedieningshandleiding | HP XQ - Bedieningshandleiding | | ||

| LP XQ - Bedieningshandleiding | LP XQ - Bedieningshandleiding | | ||

| Expert XQ 2.0 - Bedieningshandleiding | Expert XQ 2.0 - Bedieningshandleiding | | ||

| Titan XQ puls - Bruksanvisning | Titan XQ puls - Bruksanvisning | | ||

| Drive XQ - Bruksanvisning | Drive XQ - Bruksanvisning | | ||

| HP XQ - Bruksanvisning | HP XQ - Bruksanvisning | | ||

| LP XQ - Bruksanvisning | LP XQ - Bruksanvisning | | ||

| Expert XQ 2.0 - Bruksanvisning | Expert XQ 2.0 - Bruksanvisning | | ||

| Titan XQ puls - Instrukcja obsługi | Titan XQ puls - Instrukcja obsługi | | ||

| Drive XQ - Instrukcja obsługi | Drive XQ - Instrukcja obsługi | | ||

| HP XQ - Instrukcja obsługi | HP XQ - Instrukcja obsługi | | ||

| LP XQ - Instrukcja obsługi | LP XQ - Instrukcja obsługi | | ||

| Expert XQ 2.0 - Instrukcja obsługi | Expert XQ 2.0 - Instrukcja obsługi | | ||

| Titan XQ puls - Руководство по эксплуатации | Titan XQ puls - Руководство по эксплуатации | | ||

| Drive XQ - Руководство по эксплуатации | Drive XQ - Руководство по эксплуатации | | ||

| HP XQ - Руководство по эксплуатации | HP XQ - Руководство по эксплуатации | | ||

| LP XQ - Руководство по эксплуатации | LP XQ - Руководство по эксплуатации | | ||

| Expert XQ 2.0 - Руководство по эксплуатации | Expert XQ 2.0 - Руководство по эксплуатации | | ||

| Titan XQ puls - Üzemeltetési utasítás | Titan XQ puls - Üzemeltetési utasítás | | ||

| Drive XQ - Üzemeltetési utasítás | Drive XQ - Üzemeltetési utasítás | | ||

| HP XQ - Üzemeltetési utasítás | HP XQ - Üzemeltetési utasítás | | ||

| LP XQ - Üzemeltetési utasítás | LP XQ - Üzemeltetési utasítás | | ||

| Expert XQ 2.0 - Üzemeltetési utasítás | Expert XQ 2.0 - Üzemeltetési utasítás | | ||

| Titan XQ puls - Návody k obsluze | Titan XQ puls - Návody k obsluze | | ||

| Drive XQ - Návody k obsluze | Drive XQ - Návody k obsluze | | ||

| HP XQ - Návody k obsluze | HP XQ - Návody k obsluze | | ||

| LP XQ - Návody k obsluze | LP XQ - Návody k obsluze | | ||

| Expert XQ 2.0 - Návody k obsluze | Expert XQ 2.0 - Návody k obsluze | | ||

| Titan XQ puls - Kullanim kilavuzu | Titan XQ puls - Kullanim kilavuzu | | ||

| Drive XQ - Kullanim kilavuzu | Drive XQ - Kullanim kilavuzu | | ||

| HP XQ - Kullanim kilavuzu | HP XQ - Kullanim kilavuzu | | ||

| LP XQ - Kullanim kilavuzu | LP XQ - Kullanim kilavuzu | | ||

| Expert XQ 2.0 - Kullanim kilavuzu | Expert XQ 2.0 - Kullanim kilavuzu | | ||

| Titan XQ puls - Käyttöohje | Titan XQ puls - Käyttöohje | | ||

| Drive XQ - Käyttöohje | Drive XQ - Käyttöohje | | ||

| HP XQ - Käyttöohje | HP XQ - Käyttöohje | | ||

| LP XQ - Käyttöohje | LP XQ - Käyttöohje | | ||

| Expert XQ 2.0 - Käyttöohje | Expert XQ 2.0 - Käyttöohje | | ||

| HP XQ - Manual de instruções | HP XQ - Manual de instruções | | ||

| LP XQ - Manual de instruções | LP XQ - Manual de instruções | | ||

| Expert XQ 2.0 - Manual de instruções | Expert XQ 2.0 - Manual de instruções | |